Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Struggling to find the right structural or finishing component? You might be overlooking a versatile hero. I’ve seen many projects benefit greatly from the right aluminum profile angle.

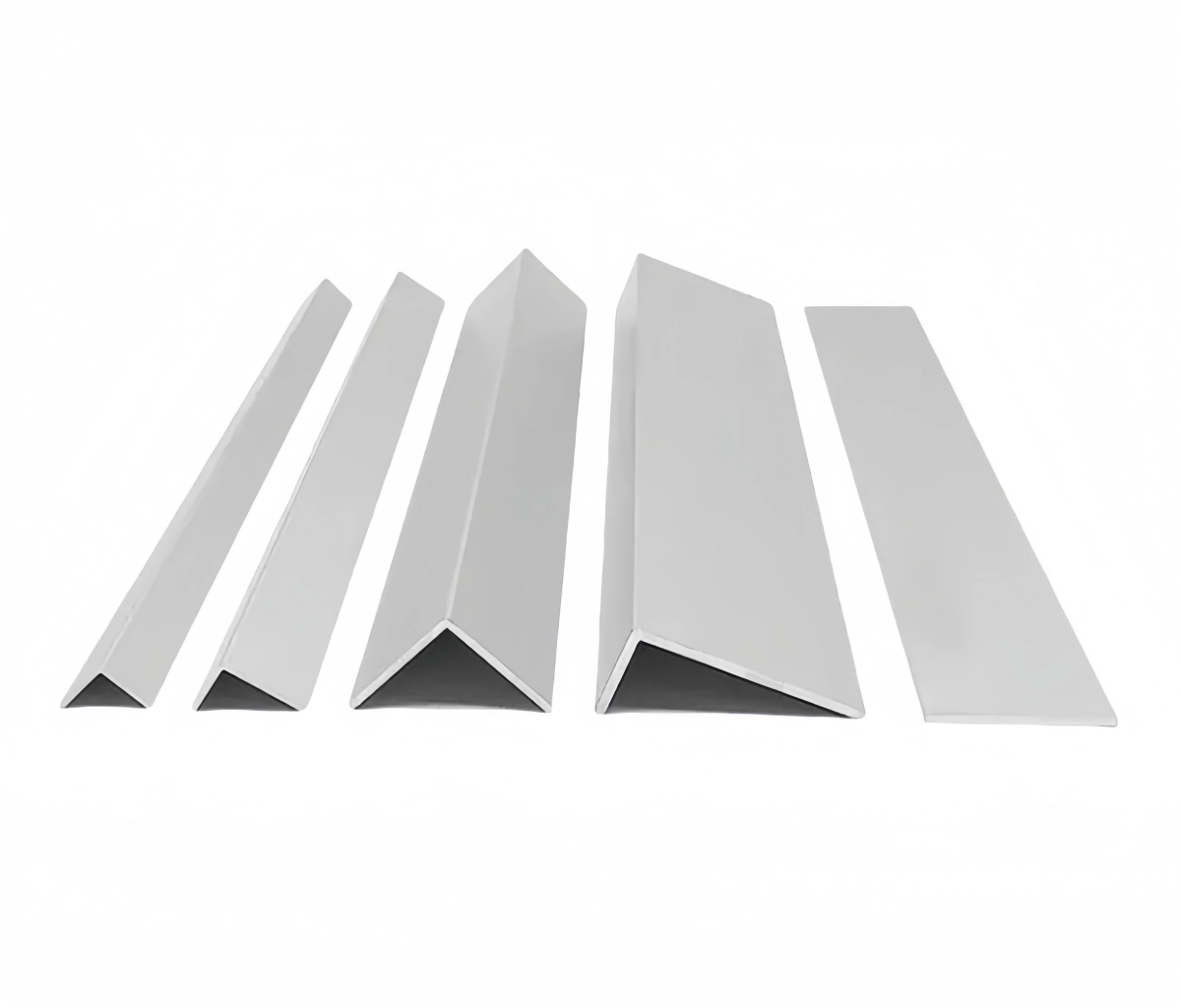

From my experience, an aluminum profile angle is an incredibly versatile extruded aluminum product. It features an L-shape, providing excellent structural support and a clean finish for countless applications. It’s a go-to for its strength, light weight, and corrosion resistance.

This simple yet effective component has so much to offer. Let’s explore what makes aluminum profile angle a fantastic choice for your demanding projects.

Are you wondering about the specifics of this common component? It’s easy to overlook the details. I often find clients need a clear, simple explanation.

In my work, I explain that an aluminum profile angle is an L-shaped extrusion. It’s made from aluminum alloy, offering a fantastic balance of light weight and good strength. We see it used everywhere!

An aluminum profile angle is, at its core, a piece of aluminum that has been formed into an L-shape. This shape is achieved through a process called extrusion. Imagine squeezing toothpaste from a tube; extrusion is similar but uses much higher pressure and heated aluminum. A billet of aluminum is heated and forced through a die that has the desired L-shape cutout. The result is a long, continuous piece of aluminum profile angle that can then be cut to specific lengths.

The material itself is key. Aluminum is chosen for several reasons:

Not all aluminum is the same. The specific alloy used for an aluminum profile angle impacts its properties. Two common alloys you’ll encounter are 6061 and 6063.

The choice between these alloys depends on the specific needs of your project. For our clients, we help them select the right alloy to ensure the aluminum profile angle performs as expected.

The extrusion process is fundamental to creating an aluminum profile angle.

This process allows for complex shapes to be created with tight tolerances, making aluminum profile angle a very precise and consistent product.

Feeling unsure where this versatile component fits best? Many wonder about its practical applications. I’ve seen aluminum profile angle solve problems in so many industries.

Based on my projects, aluminum profile angle is a star in construction for framing and supports. It’s also vital in manufacturing for machine guards and custom fixtures. The uses are truly widespread!

The versatility of aluminum profile angle means it finds its way into a vast array of applications. Its combination of light weight, strength, corrosion resistance, and ease of fabrication makes it an ideal choice for many situations. As purchasing managers, you’ll likely encounter requests for it across various product lines.

This is perhaps the most common area where you’ll see aluminum profile angle.

In a factory or manufacturing setting, aluminum profile angle is indispensable.

The table below highlights some specific industrial uses and the benefits aluminum profile angle brings:

| Industrial Application | Key Benefits of Aluminum Profile Angle |

| Automated Machinery Frames | Lightweight for easier integration, precise dimensions, corrosion resistance |

| Robotics Enclosures | Customizable, good strength-to-weight ratio, easy to modify |

| Inspection Table Structures | Stable, non-magnetic (important for some sensors), clean appearance |

| Cleanroom Equipment | Easy to clean, corrosion-resistant, can be anodized for extra protection |

Beyond industrial and large-scale construction, aluminum profile angle is a favorite for smaller projects and hobbyists.

Understanding these common uses helps you, as a purchasing manager, anticipate demand and recognize the value of sourcing high-quality aluminum profile angle for your company’s diverse needs. We often work with clients who discover new applications for it once they understand its capabilities.

Are you thinking all L-shaped aluminum is the same? It’s a common misconception. I always advise clients that the “type” really matters for performance.

From my experience, yes, there are different types! You’ll find aluminum profile angle varying in leg length (equal or unequal), alloy composition, and surface finish. Each type suits different needs.

Indeed, not all aluminum profile angle is created equal. Understanding the distinctions is crucial for sourcing the correct material for your specific applications. These differences primarily lie in their dimensions, the aluminum alloy used, and the surface finish applied. For a purchasing manager, knowing these variations ensures you’re specifying and acquiring the most suitable and cost-effective option.

The most obvious difference is in the dimensions of the “legs” of the L-shape.

We touched on alloys earlier, but it’s worth reiterating their importance in defining “types” of aluminum profile angle. The choice of alloy significantly affects:

The table below shows a comparison of common alloys used for aluminum profile angle:

| Alloy | Primary Characteristics | Common Applications |

| 6063 | Excellent finish, good corrosion resistance, easily anodized | Architectural trim, window/door frames, decorative |

| 6061 | Good strength, good machinability, good weldability | Structural components, machine parts, general fabrication |

| 6082 | Higher strength than 6061, good corrosion resistance | Highly stressed applications, trusses, bridges |

The “as-extruded” aluminum profile angle is known as “mill finish.” However, various surface finishes can be applied to enhance appearance, durability, or other properties:

Understanding these different types of aluminum profile angle ensures you can specify precisely what your engineering or production teams need, avoiding costly mistakes or performance issues.

Concerned about whether aluminum can handle the load? It’s a valid question. I often explain that the strength of aluminum profile angle comes from several factors.

In my projects, I’ve seen how the inherent properties of aluminum alloys, the L-shape geometry, and specific heat treatments all contribute to making aluminum profile angle surprisingly strong for its weight.

The strength of an aluminum profile angle isn’t just about the raw material; it’s a combination of material science, geometric design, and processing. For purchasing managers dealing with engineering requirements, understanding these factors helps in appreciating why a seemingly lightweight component can be so robust and reliable for various applications.

Aluminum itself, especially when alloyed, has an excellent strength-to-weight ratio. This is a primary reason for its widespread use.

The “angle” shape itself is inherently strong and rigid.

For many high-strength aluminum alloys like 6061, heat treatment, also known as tempering, is a critical step in achieving maximum strength.

The table below outlines factors influencing the strength of an aluminum profile angle:

| Strength Factor | Description | Impact on Aluminum Profile Angle |

| Alloy Composition | Specific elements added to aluminum (e.g., Mg, Si, Cu) | Determines base mechanical properties like tensile and yield strength. |

| Geometric Shape (L) | The cross-sectional design of the profile. | Provides inherent resistance to bending and buckling. |

| Material Thickness | The gauge of the aluminum used in the legs of the angle. | Thicker material generally means higher load-bearing capacity. |

| Temper / Heat Treatment | Processes like solution heat treating and aging (e.g., T6 temper). | Significantly increases hardness, tensile strength, and yield strength. |

| Manufacturing Quality | Consistency of the extrusion process, absence of defects. | Ensures the profile meets specified strength and dimensional tolerances. |

As a supplier, we ensure that the aluminum profile angle we provide, whether a standard item or a custom extrusion, meets the specified alloy and temper requirements. This guarantees that our clients receive parts with the expected strength and performance characteristics, addressing their concerns about quality control and product reliability.

In short, aluminum profile angle is a remarkably useful and adaptable material. Its various types and strengths make it perfect for many projects.