Адрес

304 Северный кардинал

Улица Дорчестер Сентер, MA 02124

Рабочие часы

Понедельник - пятница: 7AM - 7PM

Выходные: 10AM - 5PM

Адрес

304 Северный кардинал

Улица Дорчестер Сентер, MA 02124

Рабочие часы

Понедельник - пятница: 7AM - 7PM

Выходные: 10AM - 5PM

Struggling to find a versatile material for your project? I know that the wrong choice can lead to costly delays. I’ve discovered that the right material makes all the difference for success.

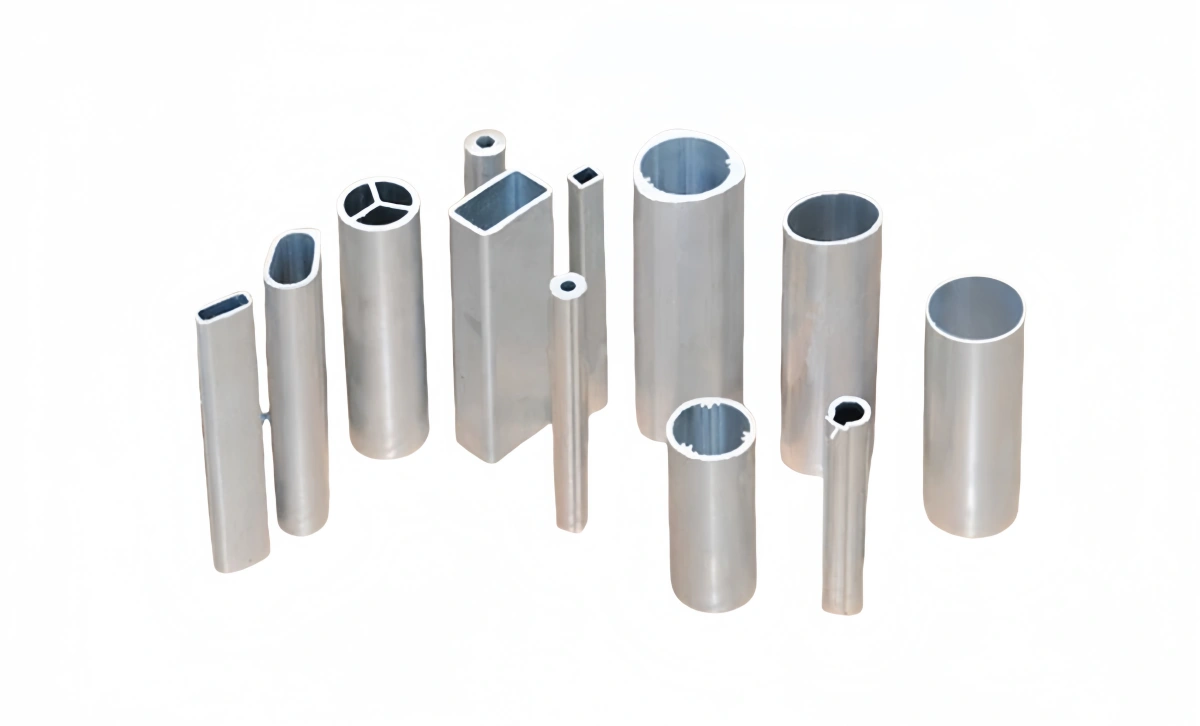

In my experience, the ultimate, game-changing secret of round aluminum extrusion is its perfect blend of lightweight properties and exceptional strength. This combination allows for incredible design freedom and cost-effective performance, making it a superior choice for many applications.

But what is this material, really? And how can its unique properties benefit your specific needs? Let’s break it down, step by step, to see if it’s the right fit for your next project.

Confused by industry jargon? Using the wrong term can lead to ordering mistakes. Let’s clarify exactly what we mean by this specific profile and why precision matters for your final product.

From my factory floor perspective, a round aluminum extrusion is a precisely shaped aluminum profile created by forcing a heated aluminum billet through a die. The result is a seamless, hollow or solid, round tube with uniform wall thickness and excellent structural integrity.

To really understand a round aluminum extrusion, it helps to break down the term. “Extrusion” is the manufacturing process itself. Think of squeezing toothpaste from a tube; the paste comes out in the shape of the circular opening. Aluminum extrusion works on a similar principle, but with immense heat and pressure.

We start with a solid block of aluminum alloy called a “billet.” We heat this billet to a high temperature, making it malleable but not molten. Then, a powerful hydraulic press pushes the billet through a shaped opening, known as a “die.” The aluminum emerges on the other side as a long, perfectly shaped profile.

A key detail is that a round aluminum extrusion can be either solid or hollow. A solid profile is a round bar or rod. It offers maximum strength and is used where weight is less of a concern than pure load-bearing capacity.

A hollow profile is a tube. This is where things get interesting for many applications. Creating a hollow tube significantly reduces the material’s weight while maintaining impressive structural stability. This makes it ideal for frames and conduits where weight is a critical factor. The precision of the process ensures the tube’s wall thickness is consistent, which is vital for balanced strength. As a purchasing manager, understanding this difference is crucial for specifying the most cost-effective solution.

Here is a simple table to compare the two main types:

| Характеристика | Solid Round Extrusion | Hollow Round Extrusion |

| Primary Use | High-stress structural components | Frames, conduits, lightweight structures |

| Weight | Heavier | Lighter |

| Material Cost | Higher (more material) | Lower (less material) |

| Example | Axles, support pins | Handrails, machine frames, piping |

Getting this basic definition right is the first step. It ensures that when you send a request for quotation (RFQ), you and your supplier are speaking the same language. This clarity prevents costly errors.

Ever wonder how your parts are actually made? Not knowing the process can make it hard to spot a quality supplier. I’ll walk you through the factory process we use daily.

I’ve overseen this process countless times. First, we heat a solid aluminum billet to about 500°C. Then, a powerful hydraulic press pushes it through a hardened steel die, shaping it into a continuous round aluminum extrusion profile that we then cool and cut.

The manufacturing of a round aluminum extrusion profile is a multi-step process. Control at each stage is vital for the final quality. Any deviation can affect the dimensional tolerance and material strength of your component, leading to assembly problems.

It all begins with the raw material: a large, cylindrical log of aluminum alloy called a billet. We select the specific alloy, like 6061 or 6063, based on your requirements. The billet is cut to length and loaded into an oven, where it is heated to a precise temperature, typically between 450°C and 500°C (850°F – 930°F).

Once heated, the malleable billet is transferred to the extrusion press. A hydraulic ram applies immense pressure, pushing the softened aluminum through the shaped opening of the steel die. It emerges on the other side as a fully formed round aluminum extrusion profile, which is guided onto a runout table.

As the profile leaves the die, it is cooled in a controlled way, either by air or a water bath. This cooling process, called quenching, sets the material’s temper and mechanical properties. After cooling, the long profile is moved to a stretcher, which pulls it to correct any minor twisting and ensure it is perfectly straight.

Finally, the straightened profile is cut to the desired lengths. For many alloys, a final step is required: artificial aging or “heat treatment.” The cut extrusions are placed in an aging oven for several hours to harden the aluminum to its full strength (e.g., a T5 or T6 temper). This is how we guarantee the mechanical properties on your spec sheet.

Is your current material too heavy, hard to work with, or prone to rust? These issues can kill your profit margins. Discover the advantages that give your product a competitive edge.

The main benefit I always highlight to my clients is the amazing strength-to-weight ratio. You get the durability needed for structural parts without the weight of steel, which saves on shipping and makes handling easier. It’s a real game-changer for product design.

When purchasing managers evaluate materials, they are looking for a combination of performance, cost, and reliability. Round aluminum extrusion scores high marks in all these areas.

This is the most celebrated benefit. Aluminum is about one-third the weight of steel, but certain alloys can be engineered to have incredible strength. This means you can design parts that are strong and rigid but also lightweight. For your business, this translates directly into lower shipping costs and makes assembly easier for your team.

Aluminum naturally forms a protective oxide layer on its surface. This thin, tough layer prevents the metal from rusting. For products used outdoors or in moist environments, this is a massive advantage. It reduces the need for expensive coatings, saving you a production step and cost.

Aluminum is an excellent conductor of both heat and electricity. This makes round aluminum extrusion a top choice for electrical applications and heat sinks. The material efficiently pulls heat away from sensitive electronic components, improving the performance and lifespan of products like LED lights.

| Property | Round Aluminum Extrusion (6061-T6) | Mild Steel |

| Density | Low (approx. 2.7 g/cm³) | High (approx. 7.85 g/cm³) |

| Устойчивость к коррозии | Excellent | Poor (requires coating) |

| Machinability | Excellent | Good |

| Проводимость | High (Thermal & Electrical) | Низкий |

Stuck on how to use a material? Limiting your imagination limits your product’s potential. Let me show you where this versatile profile is already succeeding across many industries.

I’ve supplied round aluminum extrusion for so many projects. We see it everywhere from structural frames for machinery and architectural handrails to lightweight tubes for medical equipment and custom heat sinks for LED lighting. Its versatility is its greatest strength.

The versatility of round aluminum extrusion means it appears in a surprising number of products we use every day. Its adaptability allows engineers to use it in diverse fields, leveraging its specific benefits for each application.

In the industrial sector, strength and durability are key. Hollow round aluminum extrusion is a favorite for building modular frames for automation equipment and safety guards. It’s easy to cut, drill, and assemble, which speeds up fabrication time. Solid round extrusions are used as shafts, axles, and support elements within machines.

You will find aluminum tubes everywhere in modern construction. They are used for handrails, curtain rods, and furniture frames. In these applications, its light weight, corrosion resistance, and ability to be finished with an attractive surface are major advantages.

This is a huge market for us. My customers, who often assemble products like LED lights or appliances, rely heavily on this material. A hollow round aluminum extrusion serves as the perfect housing for many LED fixtures. It provides structure and acts as a heat sink to draw heat away from the LED chips.

| Приложение | Key Benefit Leveraged | Why It’s a Good Fit |

| Machine Frame | Strength-to-Weight, Modularity | Easy to assemble; strong enough for guards and light structures. |

| LED Light Housing | Thermal Conductivity | Dissipates heat effectively, protecting electronic components. |

| Outdoor Handrail | Corrosion Resistance, Finish | Will not rust in rain and can be anodized for aesthetics. |

| Medical Walker | Light Weight, Strength | Easy for users to lift while being strong enough for support. |

Understanding these common uses can spark ideas for how a round aluminum extrusion can improve your own products by replacing heavier or less durable materials.

Round aluminum extrusion offers an ultimate mix of strength, light weight, and versatility. It’s a smart, reliable choice for improving your product design and manufacturing process.