Адрес

304 Северный кардинал

Улица Дорчестер Сентер, MA 02124

Рабочие часы

Понедельник - пятница: 7AM - 7PM

Выходные: 10AM - 5PM

Адрес

304 Северный кардинал

Улица Дорчестер Сентер, MA 02124

Рабочие часы

Понедельник - пятница: 7AM - 7PM

Выходные: 10AM - 5PM

I’ve seen the struggle. Architects and builders often face tough choices with materials. They need something strong, light, and flexible for modern designs.

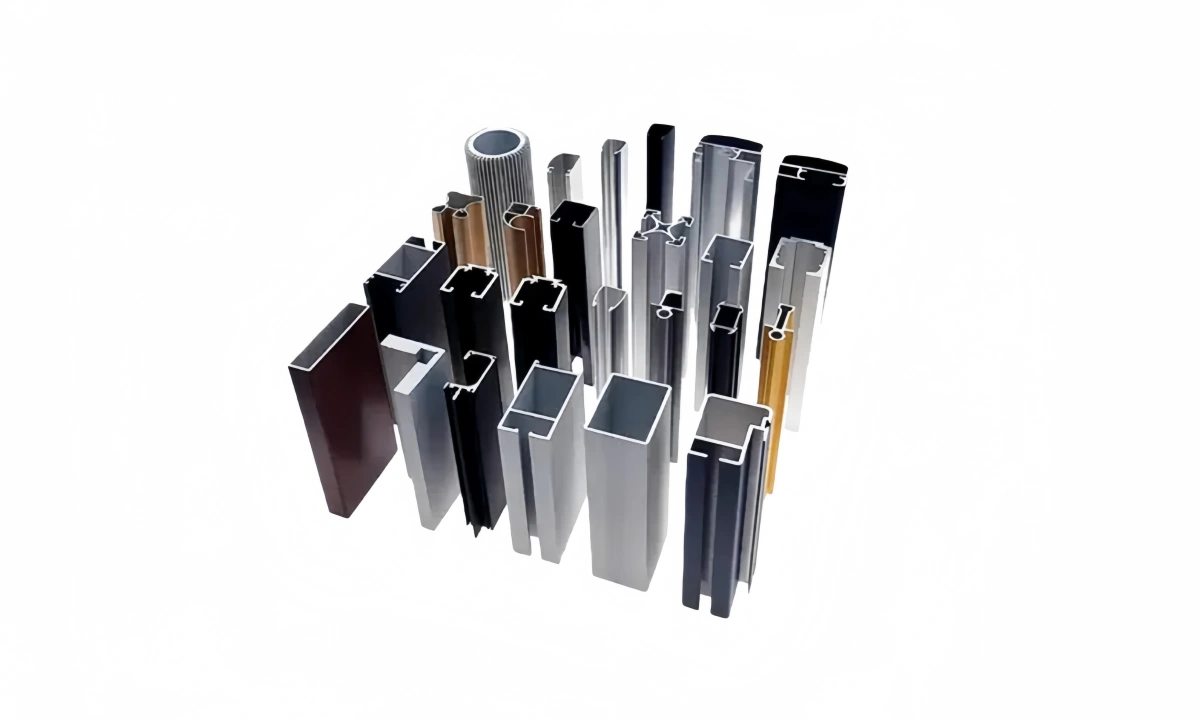

Architectural aluminum extrusions are critical because they offer unmatched versatility and durability for building projects. They provide design freedom and structural integrity, meeting diverse construction demands efficiently.

Let’s dive deeper into how these amazing architectural aluminum extrusions can transform your next project. You shouldn’t overlook their power.

I often hear questions about how these versatile architectural aluminum extrusions are truly applied. It’s a valid concern when planning a large project.

Architectural aluminum extrusions are primarily used in building facades, window and door frames, curtain walls, and interior design elements. Their lightweight strength supports diverse structural and aesthetic needs.

Architectural aluminum extrusions are used for many things in buildings. They make up parts of walls that face outside. Examples include window frames and door frames. These frames hold glass in place for windows and doors.

They also help build curtain walls. Curtain walls are outer coverings of buildings. These walls do not carry the weight of the roof or floors. Instead, they keep weather out. They also look good.

Inside buildings, architectural aluminum extrusions are used for decorative parts. This includes trim, partitions, and light fixtures. They can also form handrails and other safety features.

| Application Area | Specific Examples | Key Benefits |

| Building Exteriors | Window frames, door frames, curtain wall systems, storefronts, sunshades | Weather resistance, aesthetic appeal, structural support |

| Interior Systems | Partitions, trim, ceiling grids, lighting fixtures, handrails | Design flexibility, ease of installation, modern look |

| Structural Components | Support beams (in certain applications), framework for custom designs | High strength-to-weight ratio, corrosion resistance |

Many types of buildings use these architectural aluminum extrusions. Commercial buildings, like offices and shopping centers, use them a lot. This is because aluminum can be shaped into many forms. It also lasts a long time.

Residential buildings also use them for windows and doors. Public buildings, such as schools and hospitals, benefit from their strength and low maintenance. Even industrial buildings use these architectural aluminum extrusions for specific parts.

The ability to customize shapes is a big reason for their use. Aluminum can be pushed through a die. This makes long pieces with specific cross-sections. This process is called extrusion.

Architects can design unique shapes for their buildings. These shapes would be hard to make with other materials. This means better designs and more creative buildings.

Also, aluminum does not rust. This makes it good for outside use. It can stand up to rain, sun, and other weather conditions. This means less need for repairs over time. This saves money in the long run. The versatility of architectural aluminum extrusions makes them a preferred choice.

I often get asked if all architectural aluminum extrusions are the same. It’s a common question. The answer is important for your project.

Yes, there are different types of architectural aluminum extrusions based on their alloy, temper, and profile shape. Each type offers specific properties suited for various building applications and performance needs.

There are indeed different kinds of architectural aluminum extrusions. These differences come from a few main things. One is the aluminum alloy used.

Another is how the aluminum is treated for strength. This is called its temper. The last is the actual shape, or profile, of the extrusion. Each of these factors changes how the extrusion performs.

This means that for different parts of a building, you need different types of architectural aluminum extrusions. Choosing the right type is key for the success of any building project. It makes sure the part works as it should. It also makes sure the part lasts a long time.

| Alloy Series | Key Characteristics | Typical Applications |

| 6061 | Good strength, good corrosion resistance, weldable | Structural components, frames, general architectural uses |

| 6063 | Excellent finish, good corrosion resistance, moderate strength | Window/door frames, decorative trim, curtain walls (most common) |

| 6005/6005A | Higher strength than 6063, good formability | Structural elements, rail applications, more demanding frames |

The alloy refers to the mix of metals in the aluminum. For architectural uses, the 6000 series alloys are most common. For example, 6063 is very popular for architectural aluminum extrusions.

It has a good surface finish. It also resists rust well. It is not the strongest alloy. But it is strong enough for many building parts like window frames.

Another alloy is 6061. This one is stronger than 6063. It is used when parts need more strength. Both 6061 and 6063 have good resistance to corrosion. This means they do not get damaged by air or water easily. This is important for parts that are outside.

Temper refers to how hard or strong the aluminum is. This is controlled by heat treatment. For example, T5 temper means the aluminum is aged and cooled to a certain strength. T6 temper means it is even stronger because of more heat treatment.

The temper chosen depends on how much stress the part will face. For instance, a main structural beam might need a T6 temper. A decorative piece might only need T5.

The profile shape is also very important. This is the cross-section of the aluminum piece. It can be a simple square. Or it can be a complex shape with many hollow areas. Complex shapes help save weight. They also add strength where needed. They allow for hidden fasteners or special connections. Architects design these profiles for specific functions. This includes holding glass or connecting panels. These varied types of architectural aluminum extrusions allow for diverse applications.

I know the search for reliable suppliers can be a headache. You need a partner you can trust to deliver quality architectural aluminum extrusions.

You can find quality architectural aluminum extrusions from established manufacturers and suppliers with strong reputations, often located in key industrial regions like China. Look for companies that emphasize consistent quality control and offer full supply chain services.

Finding good quality architectural aluminum extrusions is very important for any building project. The best place to start looking is with manufacturers who have been in business for a long time. These companies usually have good reputations. They know how to make extrusions that meet high standards.

Many of these reliable manufacturers are found in places like China. Companies there often have large factories. They also have a lot of experience. They have good systems for checking quality.

When you search for a supplier, you should look for one that controls quality well. They should check products at every step. Also, a good supplier will offer full services. This means they help with everything from taking your order. They also make sure it arrives at your door. This makes the whole process smoother for you.

| Factor | Описание | Why it Matters |

| Factory Size & Capacity | Large facilities, high production volume | Ensures ability to handle large orders and consistent supply |

| Quality Control Systems | Certifications (e.g., ISO), in-house testing | Guarantees product meets specifications and standards |

| Supply Chain Services | Order management, logistics, quality inspection | Reduces your workload and potential shipping problems |

| Engineering Support | Ability to assist with design and technical issues | Helps optimize designs and solve complex problems |

| Communication & Professionalism | Clear, concise, and timely responses | Avoids misunderstandings and project delays |

When I talk to clients, they often share their pain points about suppliers. One big problem is when sales representatives lack knowledge. This leads to bad communication. It also leads to unprofessional replies. My company, ALUT, understands these issues well.

We make customized aluminum products, including architectural aluminum extrusions. We are a factory in China. We have over 10,000 square meters of space. We work only with businesses (B2B).

Our team provides complete supply chain services. This includes managing orders. It also includes checking quality. We handle logistics too. We export to the United States, Canada, and Europe.

Our customers are often purchasing managers or executives of big companies. They want suppliers who are good at engineering, service, and project management. We focus on these areas to make sure our customers get what they need.

We also offer flexible payment terms. These can include credit. This helps our clients manage their cash flow better. We know that delays and poor quality can stop production for our customers. So, we work hard to prevent these problems. We ensure our products meet exact design requirements. We also ensure they are delivered on time. We specialize in providing high-quality architectural aluminum extrusions.

I know appearances matter a lot in architecture. You’re probably wondering what choices you have to make these architectural aluminum extrusions look their best.

Many finishing options are available for architectural aluminum extrusions, including anodizing, powder coating, and mechanical finishes. These options enhance appearance, improve durability, and provide corrosion protection.

There are many different ways to finish architectural aluminum extrusions. These finishes do more than just make the aluminum look good. They also make the material stronger. They help it last longer. They protect the aluminum from rust and wear.

The most common finishes are anodizing, powder coating, and some mechanical finishes. Each type of finish has its own set of benefits. It also has different looks.

Choosing the right finish depends on what the building needs. It also depends on how you want it to look. You also need to think about how much wear and tear the part will face. The finish is a key part of the design and function of the architectural aluminum extrusions.

| Finish Type | Описание | Key Benefits | Common Applications |

| Anodizing | Electrochemical process creating a thick oxide layer | Excellent corrosion resistance, hard surface, metallic look | Window frames, door frames, curtain walls, decorative panels |

| Powder Coating | Dry powder applied electrostatically, then cured with heat | Wide range of colors, good durability, impact resistance | Facade elements, interior trim, protective barriers |

| Mechanical Finishes | Brushing, polishing, sandblasting | Unique textures, specific light reflection, preparation for other finishes | Decorative items, internal features, specialized surfaces |

Anodizing is one popular way to finish aluminum. It uses electricity to create a protective layer on the aluminum’s surface. This layer is very hard. It resists rust well.

Anodizing can also be done in different colors. This gives a metallic look. Common anodized colors include clear (silver), bronze, and black.

This finish is good for outdoor parts that need to stand up to weather. It also works well for parts that get touched a lot. For example, door handles and window frames often use anodizing. It keeps them looking good for a long time. The thickness of the anodized layer can be controlled. Thicker layers mean more protection. They also mean longer life for architectural aluminum extrusions.

Powder coating is another widely used finish. In this process, a dry powder is sprayed onto the aluminum. Then, the aluminum piece is heated. This melts the powder into a smooth, strong layer.

Powder coating comes in many colors. This allows for many design choices. It also makes the aluminum very durable. It resists scratches, chips, and fading.

This finish is good for both inside and outside parts. It offers strong protection and a great look. You can choose from glossy, matte, or textured finishes.

Mechanical finishes change the surface texture without adding a layer. Examples include brushing, polishing, and sandblasting. Brushing creates fine lines for a satin look. Polishing makes the surface shiny like a mirror. Sandblasting gives a rough, matte finish.

These are often used for decorative purposes. They can also prepare the surface for other finishes. Sometimes, mechanical finishes are used alone for a unique aesthetic. This makes architectural aluminum extrusions even more versatile.

Architectural aluminum extrusions are a smart choice for any building project. They offer strength, style, and long-lasting quality. You won’t regret choosing them!