Endereço

304 Norte Cardinal

St. Dorchester Center, MA 02124

Horas de trabalho

Segunda-feira a sexta-feira: 7h - 19h

Fim de semana: 10:00 - 17:00

Endereço

304 Norte Cardinal

St. Dorchester Center, MA 02124

Horas de trabalho

Segunda-feira a sexta-feira: 7h - 19h

Fim de semana: 10:00 - 17:00

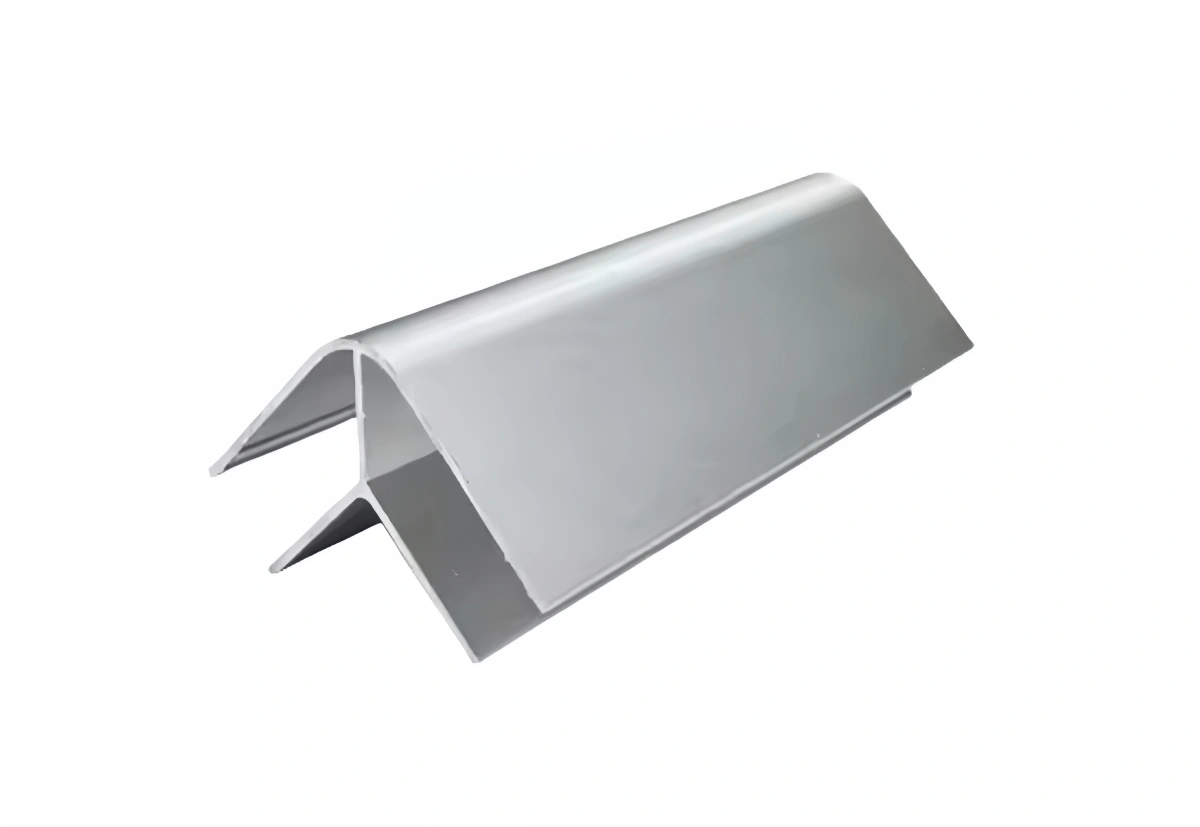

Exposed corners get chipped, damaged, and look unfinished. This compromises the quality and durability of your entire project. I’ve learned an aluminum corner extrusion is the simple, professional solution.

In my professional experience, it’s the ultimate solution because it provides unbeatable protection against impact, creates a crisp, clean aesthetic line, and simplifies installation. An aluminum corner extrusion gives every project a durable, high-end finish that I know my clients demand.

This versatile profile has many uses beyond what you might expect. Let’s explore what an aluminum corner extrusion is used for, its main benefits, the different types available, and how you can choose the perfect one for your specific application.

Projects with vulnerable corners often fail over time. Chipped drywall or damaged edges look terrible and require costly repairs. I always recommend using an aluminum corner extrusion to protect and finish them.

From what I see in our factory, it’s primarily used to protect vulnerable 90-degree corners on walls, furniture, and fixtures from damage. I also see it used decoratively to create clean lines and as a functional channel for LED lighting.

The applications for an aluminum corner extrusion are far more diverse than many people realize. While its primary role is protection, its uses have evolved to become a key part of modern design and functionality. For my clients, who are often purchasing managers or product developers, understanding this versatility is key to unlocking new design possibilities and improving the quality of their final products. It’s a component that can solve multiple problems at once—a detail that is always appreciated in efficient product design. Let’s look at the main applications I see every day.

This is the most common use. In high-traffic commercial environments like hospitals, schools, and retail stores, wall corners are constantly bumped by carts, equipment, and people. A vinyl or simple drywall corner bead will crack or dent easily. An aluminum corner extrusion, however, provides a robust shield that absorbs impact and prevents damage. It’s also used to protect the edges of countertops, custom furniture, and industrial shelving, significantly extending the life of the product.

Architects and designers use an aluminum corner extrusion to achieve sharp, clean lines that are difficult to create with other materials. It provides a perfect 90-degree angle that looks precise and intentional. This is especially popular in minimalist and industrial design styles. When used on furniture or cabinetry, it can serve as a decorative trim that adds a touch of metallic contrast and a high-end feel.

Beyond just looks and protection, some profiles are designed for specific functions. I’ve worked with clients to develop a custom aluminum corner extrusion that acts as a channel for LED strips, turning a simple corner guard into an integrated lighting fixture. Other designs are used as a transition piece between two different flooring or wall materials, like tile and drywall, creating a clean and durable seam.

| Aplicações comuns | Primary Function | Indústria |

| Wall Corner Guard | Protection from impact | Commercial, Healthcare |

| Tile Trim | Edge protection and transition | Construction, Interior Design |

| Furniture Edging | Decorative and protective | Fabrico de mobiliário |

| LED Channel | Housing and heat sink | Lighting, Architectural |

Choosing the wrong material for corner protection can be a big mistake. It might rust, crack, or fail to provide real protection. The clear benefits of an aluminum corner extrusion make it my top choice.

The main benefits I always highlight to my clients are its exceptional durability, its natural corrosion resistance, and its light weight. I’ve found an aluminum corner extrusion offers superior, long-lasting protection without adding significant bulk or requiring constant maintenance.

When a purchasing manager evaluates a component, they are looking beyond the initial unit price to the total value it provides. That is where an aluminum corner extrusion truly excels. The benefits translate directly into a better product, lower long-term costs, and higher customer satisfaction. I once had a client who manufactured display cases. They switched from a plastic corner trim to an aluminum corner extrusion, and their warranty claims for shipping damage dropped to almost zero. The slightly higher initial cost was easily paid back by the savings on repairs and replacements. This is the kind of long-term value I want my clients to understand.

Aluminum has a fantastic strength-to-weight ratio. An aluminum corner extrusion made from an alloy like 6063 or 6061 is significantly tougher than plastic or wood trim. It resists dents, scratches, and warping. This means the finished product will look good and perform well for a much longer time, even in demanding environments.

This is a huge benefit. Aluminum naturally forms a thin, protective layer of aluminum oxide when exposed to air. This layer prevents rust and corrosion. Unlike steel angles that need to be painted or galvanized to prevent rust, an aluminum corner extrusion can be used in its raw state, even in damp areas like kitchens and bathrooms, without fear of degradation.

Aluminum is about one-third the weight of steel. This makes an aluminum corner extrusion much easier to handle, cut, and install, saving valuable labor time. The lighter weight also leads to lower shipping costs, a significant factor for my B2B clients who buy in bulk and ship products internationally.

| Benefício | Impact for a Purchasing Manager |

| Durability | Lower warranty claims and higher product quality. |

| Resistência à corrosão | Suitable for more applications; lower maintenance costs. |

| Leve | Reduced shipping costs and easier, faster installation. |

| Reciclabilidade | Meets corporate sustainability goals. |

You need a corner profile, but the standard L-shape isn’t quite right. Using the wrong shape looks bad and won’t fit properly. I can help you understand the different types available to find the perfect match.

In my experience, the main types are the standard L-shape, tile trim profiles with an anchoring leg, and specialized LED channels. I often help clients choose between sharp angles, rounded edges, and profiles with grooves depending on their specific functional and aesthetic needs.

The term “aluminum corner extrusion” covers a wide family of profiles, each designed for a specific task. Knowing the different types is crucial for specifying the correct part. A client in the construction industry once ordered a standard L-angle for a tile installation. It didn’t work because it couldn’t be properly secured in the mortar bed. We quickly identified that they needed a tile trim profile with an anchoring leg. This small difference in shape was the key to a successful installation. As a supplier, my role is to ensure my clients get the exact part they need, and that starts with understanding the different profile types and their intended uses.

This is the most common type of aluminum corner extrusion. It’s a simple 90-degree profile, often with equal leg lengths (e.g., 1″ x 1″). It’s a versatile workhorse used for basic edge protection on walls, counters, and frames. It can also have unequal legs (e.g., 1″ x 2″) for applications where you need to cover more of one surface than the other.

These profiles are designed to be installed flush with the surface. They have a standard L-shape to cover the corner, but they also include a thin, perforated anchoring leg. This leg is embedded into the wall plaster or tile adhesive. This method creates a perfectly clean, integrated transition between the corner trim and the wall surface, with no visible gap.

This category includes a huge variety of shapes. You can find an aluminum corner extrusion with a rounded, or “bullnose,” edge for improved safety in schools or hospitals. There are also corner profiles with built-in channels designed specifically to hold LED strips, turning a protective corner into a light source. Other decorative profiles might have grooves or ridges for a unique visual texture.

| Tipo de perfil | Main Feature | Typical Use Case |

| Standard L-Angle | Simple 90-degree shape. | General purpose corner protection. |

| Tile Trim Profile | Has an anchoring leg. | Creating a flush edge on tiled corners. |

| LED Channel Profile | Has a hollow channel and diffuser slot. | Integrated corner lighting. |

| Rounded Profile | Has a soft, curved outer edge. | High-traffic areas where safety is a concern. |

Ordering the wrong profile leads to project delays and wasted material. It’s frustrating when the part doesn’t fit or fails in use. I use a simple checklist to ensure my clients select the perfect profile every time.

To select the right one, I always advise checking three things: the alloy and temper for strength, the dimensions for a perfect fit, and the finish for aesthetics and protection. Getting these three details right ensures the aluminum corner extrusion will perform perfectly.

Making the correct selection is a process of matching the material’s properties to the application’s demands. For a purchasing manager, getting this right from the start prevents communication errors with engineering and avoids sourcing a part that doesn’t meet quality standards. A thoughtful specification considers not just the shape, but the underlying metallurgy and surface treatment. This is where a knowledgeable supplier can provide significant value, by guiding you through these choices to find the most cost-effective solution that meets all performance criteria. This attention to detail is what separates a simple transaction from a true supply chain partnership.

The alloy is the recipe of the aluminum, and it determines its core properties. For most aluminum corner extrusion applications, you will choose between two alloys:

You need to specify three key dimensions: the length of each leg and the wall thickness. Measure your corner to ensure the legs will provide adequate coverage. The wall thickness is also critical. A thicker wall provides more durability and impact resistance but will also cost more. It’s a trade-off between performance and budget.

The finish affects both the look and the durability.

The aluminum corner extrusion is an essential component for protection and design. Choosing the right profile, alloy, and finish ensures a durable, professional result for any project.