Endereço

304 Norte Cardinal

St. Dorchester Center, MA 02124

Horas de trabalho

Segunda-feira a sexta-feira: 7h - 19h

Fim de semana: 10:00 - 17:00

Endereço

304 Norte Cardinal

St. Dorchester Center, MA 02124

Horas de trabalho

Segunda-feira a sexta-feira: 7h - 19h

Fim de semana: 10:00 - 17:00

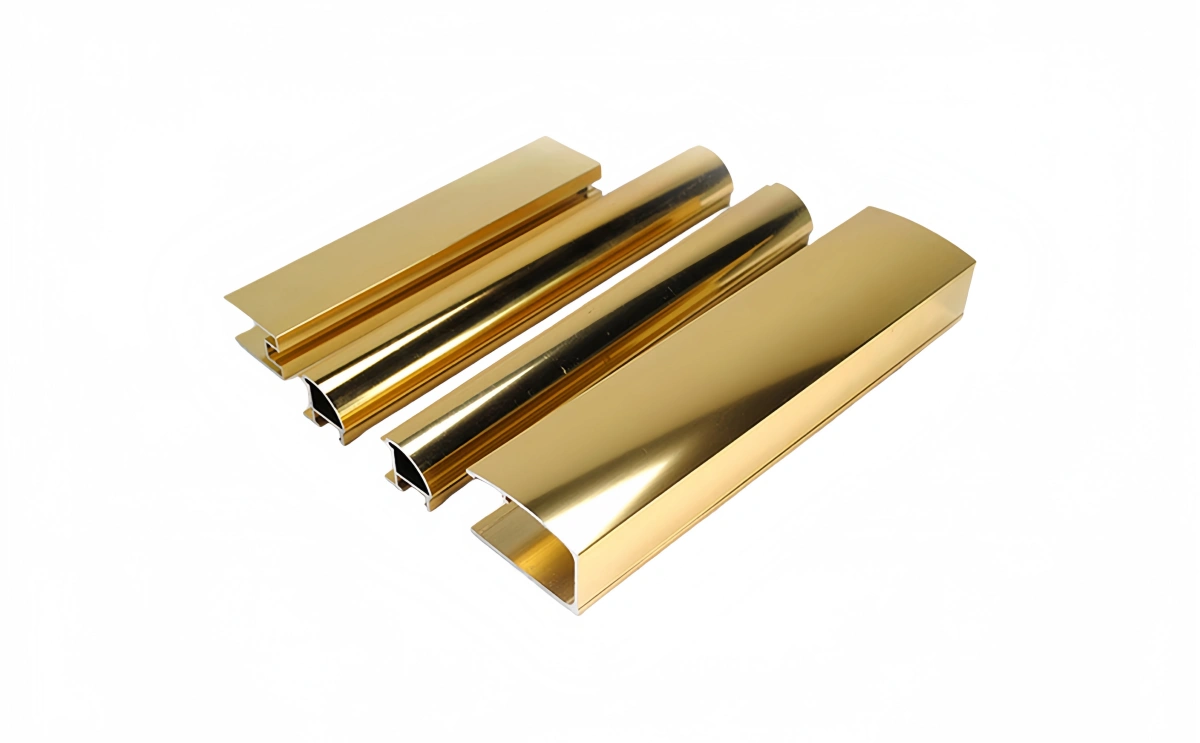

Polishing aluminum to mirror finish can be a truly challenging task, leaving many feeling frustrated. I understand this common struggle. But what if there was a guaranteed way to achieve that incredible, flawless shine? I believe you can master polishing aluminum to mirror finish.

Achieving a mirror finish on aluminum demands patience and the correct technique. It is a multi-step process that involves progressively finer abrasives, meticulous cleaning, and a final buffing stage. Anyone can master polishing aluminum to mirror finish with practice and the right approach.

Stick with me, and you’ll discover the secrets to transforming dull aluminum into a dazzling, reflective surface. Let’s make your aluminum truly shine through expert polishing aluminum to mirror finish techniques.

I often get asked, “What’s the best way to polishing aluminum to mirror finish?” It is a common question. Many people want to make their aluminum look new. I understand this desire for polishing aluminum to mirror finish.

The best way to polishing aluminum to mirror finish is through a systematic process. You start with coarser abrasives to remove imperfections. Then, you move to finer grits to smooth the surface. Finally, you use polishing compounds and buffing wheels for the ultimate shine when polishing aluminum to mirror finish.

To get a mirror finish on aluminum, you need a planned approach. It is not just one step for polishing aluminum to mirror finish. First, you must clean the aluminum well. Remove all dirt, grease, and old coatings. Use a good degreaser for this. If the surface has deep scratches or corrosion, you need to start with coarser sandpaper. This is usually around 200 or 320 grit. Work in a consistent direction. This removes the major flaws before polishing aluminum to mirror finish.

Wet sanding is a useful technique when polishing aluminum to mirror finish. It keeps the sandpaper from clogging. It also helps to get a smoother finish faster. Just dip your sandpaper in water often.

| Grit Size | Objetivo |

| 200-400 | Remove deep scratches and heavy oxidation |

| 600-1000 | Smooth the surface, remove previous grit marks |

| 1500-2000 | Prepare for compounding, achieve a semi-polished look |

| 2500-3000 | Refine surface, minimize swirl marks for mirror finish |

Once you finish sanding with the finest grit, the aluminum should look dull but smooth. It will not be shiny yet. The next step is compounding. This involves using polishing compounds and buffing wheels. Attach a buffing wheel to a drill or grinder. Apply a small amount of polishing compound to the wheel. Then, gently press the wheel against the aluminum. Move the wheel constantly to avoid overheating. Overheating can cause discoloration. You will see the shine start to appear as you work towards polishing aluminum to mirror finish. There are different compounds for different stages. Some are for cutting, and some are for finishing.

Use separate buffing wheels for each compound. This prevents cross-contamination. Cross-contamination can cause new scratches. With the right tools and careful work, you can achieve a truly amazing mirror finish on your aluminum. It takes time, but the results are worth it when you are polishing aluminum to mirror finish.

People often ask me, “How long will it take to polishing aluminum to mirror finish?” It is a fair question, especially for those new to polishing. I know time is important for polishing aluminum to mirror finish.

The time it takes to polishing aluminum to mirror finish varies greatly. It depends on the aluminum’s initial condition, the size of the piece, and your experience. A small, moderately scratched piece might take a few hours. A large, heavily oxidized item could take days for polishing aluminum to mirror finish.

Many factors affect the total time needed to polishing aluminum to mirror finish. The first factor is the initial condition of the aluminum. If the aluminum is old, dull, or has deep scratches, it will take much longer to achieve a mirror finish. You will need to start with coarser grits and spend more time on the initial sanding stages. If the aluminum is already in good shape, with only minor scuffs, the process of polishing aluminum to mirror finish will be quicker.

The size of the aluminum piece also plays a big role. Polishing a small bracket is much faster than polishing a large truck fuel tank or a set of car wheels. Larger surfaces require more sanding pads, more buffing wheels, and simply more time to cover every area evenly when polishing aluminum to mirror finish. If you are working on a very large piece, you might break the work into sections.

The tools you use can also affect how long it takes. Using power tools like orbital sanders and angle grinders with buffing attachments will be faster than doing everything by hand. Hand polishing is usually slower. It requires more effort. However, hand polishing can give you more control for very detailed or delicate areas. I often use a mix of both. Power tools for the main surface. Hand tools for edges and tight spots when polishing aluminum to mirror finish.

| Fator | Effect on Time |

| Initial Condition (Scratches/Oxidation) | More damage = Longer time for mirror finish |

| Size of Piece | Larger piece = Longer time for mirror finish |

| Tools Used (Manual vs. Power) | Manual = Longer time; Power = Shorter time for mirror finish |

| Your Experience Level | Less experience = Longer time for mirror finish |

Your experience level is another key factor. If you are new to polishing aluminum to mirror finish, you might spend more time learning the techniques. You might also make more mistakes. An experienced polisher can work more efficiently. They know how much pressure to apply. They know when to move to the next grit. They can judge the surface quality better. With practice, your speed and skill will improve. For a first-timer, even a small project might take a full day to get a mirror finish. For an expert, the same project could be done in a few hours. Remember, rushing the process can lead to a poor finish. It can also cause you to start over. It is better to take your time and do it right the first time. Quality takes time, especially for a perfect mirror polish when polishing aluminum to mirror finish.

When I first started, I wondered, “What exact tools do I even need to polishing aluminum to mirror finish?” It is easy to get lost in all the options. But I want to simplify it for you.

To polish aluminum to a mirror finish, you need a specific set of tools. These include various grits of sandpaper, polishing compounds (cutting, medium, and finishing), buffing wheels, and a power tool to drive the wheels. Safety gear is also very important for polishing aluminum to a mirror finish.

Having the right tools is key to success when polishing aluminum to a mirror finish. You cannot get good results with the wrong equipment. The most basic tools you will need are sandpaper. You need a wide range of grits. Start from rough ones, like 200 or 320 grit. Then, you need to progress through medium grits, such as 600, 800, 1000. Finally, you need very fine grits, like 1500, 2000, 2500, and 3000. These finer grits are often used for wet sanding. Wet sanding helps to get a smoother surface faster. Make sure your sandpaper is designed for metal when polishing aluminum to a mirror finish.

Next, you will need polishing compounds. These come in bars or sticks. There are different types for different stages of polishing aluminum to a mirror finish.

You will also need buffing wheels. These attach to a power tool. Buffing wheels come in different materials and stiffness. Cotton buffing wheels are common. Use separate wheels for each type of compound. This prevents mixing the compounds. Mixing compounds can cause scratches. This is crucial when polishing aluminum to a mirror finish.

A power tool is necessary for buffing. An angle grinder, a drill, or a bench grinder can work. An angle grinder is good for larger surfaces. A drill is useful for smaller, more detailed work. A bench grinder is fixed and good for steady work. Make sure the tool has variable speed control. This gives you more control over the process of polishing aluminum to a mirror finish.

Safety gear is also important. Always wear safety glasses to protect your eyes from flying debris. Gloves protect your hands from compounds and metal dust. A dust mask or respirator protects your lungs. The polishing process creates fine dust particles. These are not good to breathe in. Working in a well-ventilated area is also a good idea. Having a clean work area helps too.

After all that hard work, I know you will ask, “How do I keep this polished aluminum mirror finish looking this good?” It is a common concern. You want that shine to last.

To maintain a mirror finish on polished aluminum, regular cleaning and protection are essential. Avoid abrasive cleaners and harsh chemicals. Use mild soaps and soft cloths for washing. Apply a protective wax or sealant to create a barrier against oxidation and environmental damage, ensuring your polished aluminum mirror finish lasts.

Maintaining a mirror finish on polished aluminum requires ongoing care. It is not a one-time job. Aluminum can oxidize and tarnish over time. This makes it lose its shine. Regular cleaning is the first step. You should clean your polished aluminum often. Use a mild soap and water. Dish soap often works well. Use a soft cloth or sponge. Never use abrasive scrubbers or harsh brushes. These will scratch the delicate mirror surface. Always rinse the aluminum thoroughly with clean water. This removes all soap residue. Then, dry it immediately with a clean, soft microfiber towel. This prevents water spots on your polished aluminum mirror finish.

After cleaning, applying a protective coating is key. This coating acts as a barrier. It protects the aluminum from air, moisture, and dirt. This slows down the oxidation process. There are several types of protective coatings you can use to maintain your mirror finish on polished aluminum.

Automotive wax is a popular choice. It is easy to apply. It also adds a nice shine. Apply a thin layer of wax. Let it dry to a haze. Then, buff it off with a clean microfiber cloth. This creates a protective layer for your mirror finish. Aluminum sealants are another option. These often last longer than wax.

For the most durable protection, consider a clear coat. This is usually a clear lacquer or urethane. This type of coating forms a hard, clear layer over the aluminum. It offers excellent long-term protection for your mirror finish. However, applying a clear coat can be more complex. It might require professional application. It is more permanent. You cannot easily remove it.

Polishing aluminum to a mirror finish is a process that requires effort and the right tools. With careful sanding, compounding, and proper maintenance, you can achieve and keep that amazing shine.