Endereço

304 Norte Cardinal

St. Dorchester Center, MA 02124

Horas de trabalho

Segunda-feira a sexta-feira: 7h - 19h

Fim de semana: 10:00 - 17:00

Endereço

304 Norte Cardinal

St. Dorchester Center, MA 02124

Horas de trabalho

Segunda-feira a sexta-feira: 7h - 19h

Fim de semana: 10:00 - 17:00

Struggling with enclosures that are too heavy or expensive? These problems can seriously delay your production schedule. I’ve found a powerful solution that solves these issues for my clients.

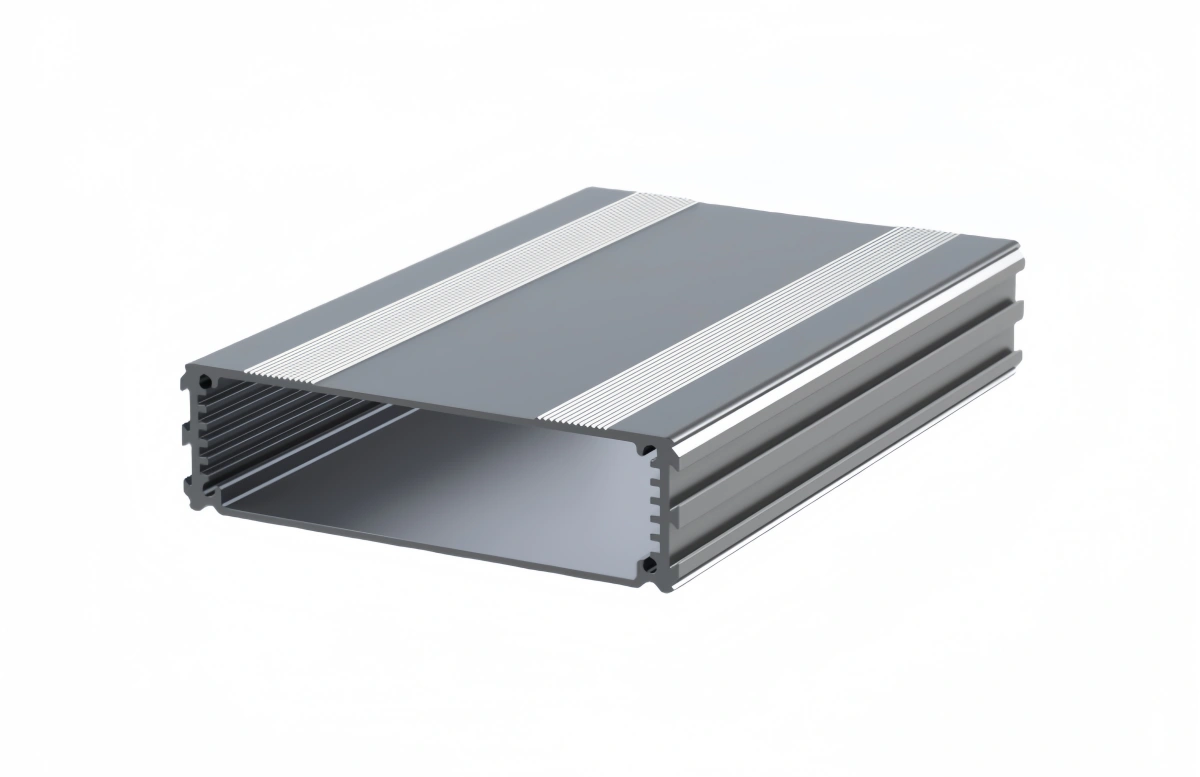

I believe an aluminum enclosure extrusion is a game-changer because it allows for creating complex, custom shapes that are both lightweight and incredibly strong. This process provides superior protection for electronics while being very cost-effective for large-scale production, a combination I find unbeatable.

But how does this all work, and what makes it the right choice for your specific needs? Let’s break it down, step by step, so you can see the value for yourself.

Heard the term but not sure what it means? This confusion can make it hard to choose the right manufacturing method. Let’s clear it up with a simple explanation.

From my perspective, an aluminum enclosure extrusion is a custom-shaped profile, created by pushing a heated aluminum billet through a die. Think of it like squeezing toothpaste from a tube. This forms a long, continuous piece with a specific cross-section, perfect for creating durable and precise housings.

To really get it, let’s look at the two parts of the term: “enclosure” and “aluminum extrusion.” An enclosure is simply a housing or case designed to protect internal components, usually electronics. An aluminum extrusion is a method of shaping aluminum by forcing it through an opening in a tool, called a die. When you combine them, you get a highly customized and efficient way to create protective cases.

The final product isn’t just a simple box. The magic of the aluminum enclosure extrusion process is that you can design complex features directly into the profile. This includes things like cooling fins, screw channels for assembly, and slots for mounting circuit boards (PCBs). This integration means you need fewer total parts, which simplifies your assembly process and reduces costs.

The process starts with two key items:

An aluminum enclosure extrusion gives you a seamless, one-piece profile that is cut to your desired length. This structural integrity is far superior to enclosures made from bent sheet metal or multiple plastic parts fastened together.

The manufacturing process seems complex and mysterious, right? This can make you feel disconnected from your supplier. I want to show you exactly how we turn a design into a product.

In my factory, the aluminum enclosure extrusion process begins by heating an aluminum billet to about 500°C. We then use a powerful hydraulic press to force it through a custom steel die. The resulting profile is cooled, stretched for straightness, and cut to the required lengths.

Understanding the step-by-step journey from a raw block of aluminum to a finished enclosure can give you confidence in the quality and consistency of your parts. At our facility, we manage this entire process with strict quality control checkpoints at every stage.

The creation of an aluminum enclosure extrusion follows a well-defined sequence of events. Each step is crucial for achieving the final product’s desired mechanical properties and dimensional accuracy.

| Step Number | Ação | Descrição |

| 1 | Die Design & Preparation | The custom steel die is designed and manufactured based on your CAD drawing. It’s preheated to prevent thermal shock. |

| 2 | Billet Heating | A solid aluminum billet is heated in a furnace to a specific temperature (450-500°C) to make it malleable. |

| 3 | Extrusão | The heated billet is pushed by a hydraulic ram through the die, emerging as a long, shaped profile. |

| 4 | Cooling (Quenching) | The profile is rapidly cooled with air or water. This step locks in the material’s molecular structure. |

| 5 | Stretching and Cutting | The profile is gripped and stretched to correct any twisting and ensure it is perfectly straight. Then it is cut. |

| 6 | Aging (Heat Treatment) | The cut profiles are placed in an aging oven to bring them to their final strength and hardness (T5 or T6 temper). |

After the primary extrusion process, the long profiles are cut into the final enclosure lengths. From there, we perform any necessary secondary machining, such as drilling mounting holes, milling openings for connectors, or cutting ventilation slots. This is where a simple profile becomes a fully functional aluminum enclosure extrusion, ready for finishing touches like anodizing or powder coating before being shipped to your assembly line.

Choosing the wrong material can be a costly mistake. It leads to heavy, weak, or rust-prone parts. I’ve seen clients gain a huge competitive advantage by making one simple material switch.

For me, the key benefits of aluminum enclosure extrusion are its incredible design flexibility and strength-to-weight ratio. I can create complex, integrated features like heat sinks and mounting channels, reducing assembly costs for my clients while providing a lightweight yet extremely durable final product.

When purchasing managers and engineers evaluate materials, they are looking for a solution that checks multiple boxes: performance, cost, and reliability. An aluminum enclosure extrusion consistently comes out on top for a wide range of applications, especially in electronics and industrial equipment. Let’s compare it directly to other common materials.

Seeing the options side-by-side makes the choice clearer. Each material has its place, but for custom housings, aluminum extrusion offers a unique balance of properties.

| Caraterística | Extruded Aluminum | Formed Steel | Molded Plastic (ABS) |

| Weight | Leve | Heavy | Very Lightweight |

| Força | High strength-to-weight ratio | Very Strong | Lower Strength |

| Resistência à corrosão | Excellent (especially when anodized) | Poor (requires plating or painting) | Excelente |

| Thermal Conductivity | Excellent (acts as a natural heat sink) | Justo | Poor (insulator) |

| Custo das ferramentas | Moderate (for the die) | High (for stamping tools) | Very High (for injection molds) |

| Customization | Very High (complex profiles are possible) | Limited (mostly simple bends and forms) | High (but design changes are expensive) |

Beyond the physical properties, an aluminum enclosure extrusion brings other powerful benefits:

A poor design can lead to manufacturing failures and wasted money. You feel frustrated when your vision doesn’t become reality. I help my clients optimize their designs for success from day one.

From my engineering background, the most critical design factors are wall thickness, tolerances, and corner radii. Getting these right ensures the part is strong, manufacturable, and fits perfectly with other components. I always review these details first on any new client drawing to prevent future problems.

To avoid delays and extra costs, it’s best to design for manufacturability (DFM) from the start. A design that looks great in a CAD program might be difficult or impossible to produce effectively. By keeping a few key principles in mind, you can ensure your aluminum enclosure extrusion is both functional and cost-effective to manufacture.

Collaborating with a supplier who understands these principles is vital. We often work with our clients to make small adjustments to their designs that can lead to big improvements in quality and cost.

| Design Factor | Recommendation | Why It’s Important |

| Uniform Wall Thickness | Keep wall thickness as consistent as possible. | Prevents uneven cooling, which can cause the profile to warp or distort. |

| Corner Radii | Avoid sharp internal corners; add a small radius. | Improves metal flow during extrusion, reducing stress and the risk of cracking. |

| Tolerâncias | Specify only critical tolerances. | Tighter, non-essential tolerances increase die complexity and cost without adding value. |

| Screw Bosses | Design with enough material for thread engagement. | Ensures screws can be securely fastened without stripping the aluminum. |

Your design should also consider the end-use. How will this enclosure be assembled? If you need to slide circuit boards into the housing, design in smooth guide channels. If you plan to fasten the enclosure with screws, make sure the screw bosses are easily accessible.

Also, think about the finish. Anodizing, for example, adds a very thin but hard layer to the surface. While it’s only a few microns thick, this can affect how tightly parts fit together. A good design accounts for these small changes in dimension from the beginning. By addressing these factors early, you create a seamless path from design to a successful, finished aluminum enclosure extrusion.

An aluminum enclosure extrusion offers unmatched flexibility, strength, and value. By understanding the process and key design factors, you can make a powerful, informed choice for your next project.