Endereço

304 Norte Cardinal

St. Dorchester Center, MA 02124

Horas de trabalho

Segunda-feira a sexta-feira: 7h - 19h

Fim de semana: 10:00 - 17:00

Endereço

304 Norte Cardinal

St. Dorchester Center, MA 02124

Horas de trabalho

Segunda-feira a sexta-feira: 7h - 19h

Fim de semana: 10:00 - 17:00

Are you tired of dealing with suppliers who cause delays and deliver poor-quality parts? This frustration is a huge risk to your project’s timeline and budget. I’ve seen it derail good companies. There is a much better way to secure your supply chain.

Based on my extensive experience, the foolproof secret to finding fantastic aluminum extrusion suppliers is a disciplined evaluation process. It’s about looking past the price tag to rigorously assess their engineering skill, quality systems, and project management. This is how I ensure a successful partnership for my clients, every time.

This proven method eliminates guesswork and helps you find a true partner who will protect your project from common pitfalls. Let’s break down exactly how you can do it.

Is your design limited by heavy materials or complex assembly? Using traditional materials like steel can inflate shipping costs and manufacturing time. This is a problem that expert aluminum extrusion suppliers can solve.

In my work, I consistently recommend using aluminum extrusion suppliers because the process provides an unmatched mix of strength, light weight, and design freedom. I’ve personally guided clients to switch to aluminum, which slashed their costs and improved their final product’s performance and appearance.

Many purchasing managers in the US and Europe come to me feeling stuck. They know there must be a better way to produce their components. The aluminum extrusion process is often the answer. It involves heating an aluminum billet and forcing it through a custom-shaped die. This creates a perfect profile that can be cut to any length. The magic of this method is its ability to produce complex shapes that would be impossible or too expensive with other methods.

When you partner with the right aluminum extrusion suppliers, you unlock significant advantages for your project. These benefits directly improve your product and your profit margins.

Here’s a clear comparison to illustrate the point:

| Caraterística | Extrusão de alumínio | Machined Steel | Injection Molded Plastic |

| Weight | Baixa | Elevado | Muito baixo |

| Força | Elevado | Muito elevado | Moderado |

| Custo das ferramentas | Moderado | Baixa | Elevado |

| Resistência à corrosão | Excelente | Poor (needs coating) | Excelente |

| Complexidade da conceção | Elevado | Moderado | Muito elevado |

For any project demanding a custom shape, low weight, and high strength, choosing to work with professional aluminum extrusion suppliers is the most strategic path to success.

Are you facing an overwhelming list of potential suppliers on Google or Alibaba? Choosing from this sea of options without a clear strategy is a recipe for disaster. I’ll show you how to find the reliable ones.

From my experience, the only way to find reliable aluminum extrusion suppliers is to use a multi-step vetting process. Start with a broad search, then aggressively filter by checking certifications, demanding proof of work, and evaluating their communication. I teach my team that this diligence is non-negotiable.

Any company can create a website. But only truly reliable aluminum extrusion suppliers can stand up to close inspection. The biggest complaints I hear from new clients are about the failures of their previous suppliers, usually in communication or quality. Your search process is the best tool to prevent this from happening to you. It’s about finding a partner, not just a price.

Begin your search with specific, long-tail keywords. Instead of a generic search, try “aluminum extrusion suppliers for electronics enclosures in Vietnam” or “ISO 9001 certified aluminum extrusion suppliers China.” This helps filter out the noise. When you land on their websites, look for signs of professionalism. Do they show clear pictures of their factory? Do they list their certifications? Do they have a dedicated section for engineering and quality control? A weak website is often a red flag.

Create a shortlist of 5-10 suppliers. Now, put them to the test.

For your top 2-3 candidates, you need to verify their operations. This can be a virtual audit. Request a live video call and ask for a tour of their production floor, their quality lab, and their warehouse. Ask to speak with the engineer who would be assigned to your project. Truly reliable aluminum extrusion suppliers will be transparent and welcome this scrutiny.

Here is a simple checklist for this phase:

| Vetting Checklist Item | Importance | Red Flags to Watch For |

| ISO 9001 Certification | Elevado | No certificate or an expired one. |

| Professional Communication | Elevado | Slow, vague, or unprofessional responses. |

| Relevant Project Experience | Elevado | Inability to provide case studies or references. |

| In-House Engineering Team | Médio | Outsources all engineering and design feedback. |

| Documented QC Process | Elevado | Cannot clearly explain how they control quality. |

This methodical approach is how you move beyond promises and find genuinely reliable aluminum extrusion suppliers who will become an asset to your business.

So many companies claim to be the best. But what does that actually mean in practice? Vague promises on a website mean nothing when a shipment is late or a part is out of spec.

In my view, the best aluminum extrusion suppliers are defined by three non-negotiable qualities: deep engineering knowledge, relentlessly transparent communication, and meticulous project management. I built my own company, ALUT, on these principles because they are the only real defense against the problems my clients fear most.

A successful manufacturing partnership is never a coincidence. It is the direct result of a supplier’s dedication to excellence in these specific areas. When you evaluate potential aluminum extrusion suppliers, you must look for concrete evidence of these qualities. Don’t settle for anything less.

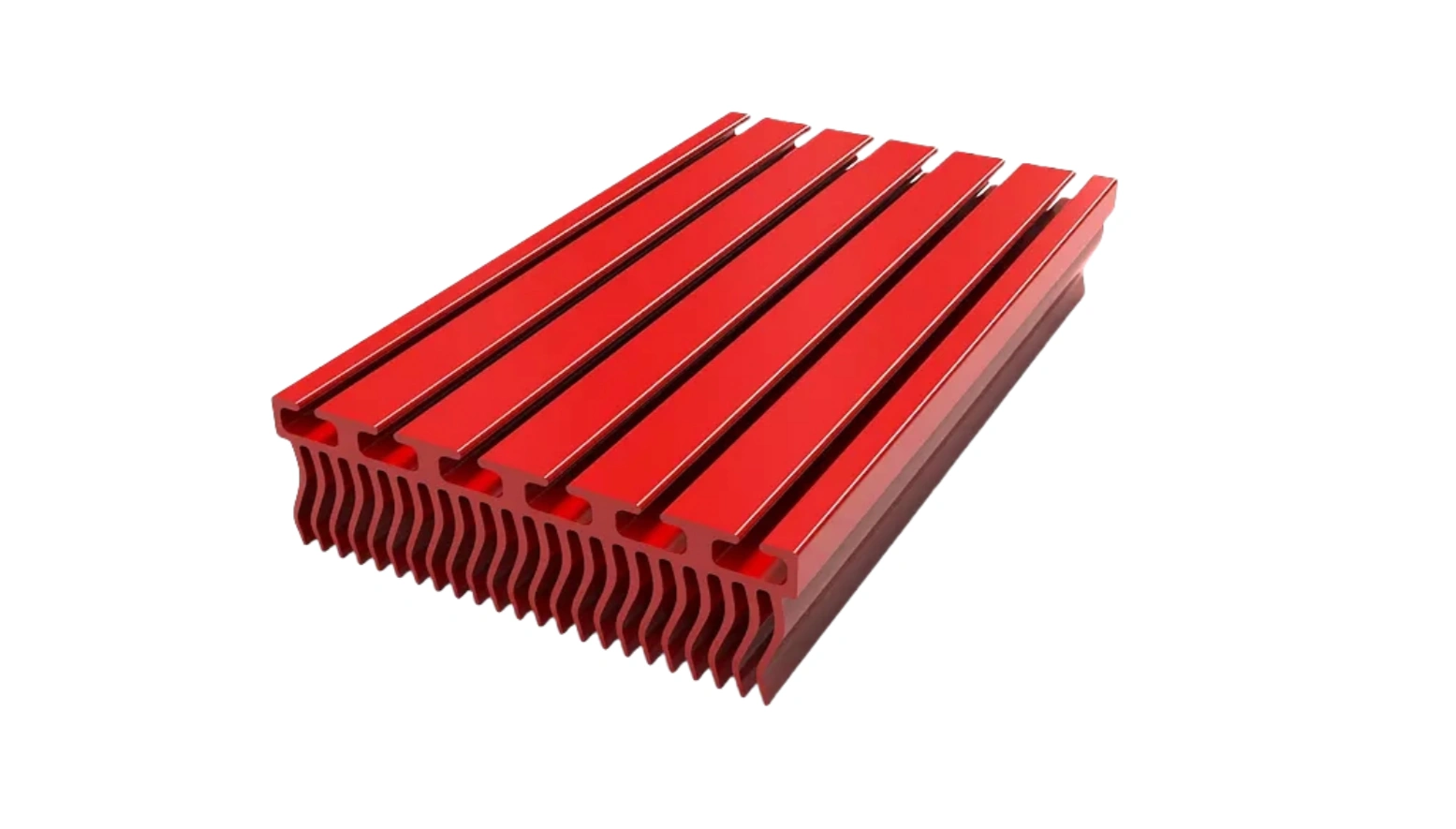

A great supplier is an active partner, not a passive order-taker. They should provide expert Design for Manufacturability (DFM) feedback on every new project. This is where their engineers analyze your design and propose improvements. These suggestions might make the part stronger, easier to produce, or cheaper—all without compromising its function. I once had a client with a design for a heat sink that was very difficult to extrude. Our engineers proposed a small change to the fin geometry that dramatically improved producibility and thermal performance. This kind of proactive, value-added input is the hallmark of the best aluminum extrusion suppliers.

One of the most damaging pain points in this industry is poor communication. Buyers tell me stories of sales reps who don’t understand technical issues or suppliers who hide delays until the last minute. The best aluminum extrusion suppliers solve this with a knowledgeable team and a policy of total transparency. Your contact person should be able to answer your questions clearly or get you a quick, accurate answer from engineering. They must be proactive. If a raw material shipment is delayed or a machine requires maintenance that might affect your schedule, they must inform you immediately and present a solution. This builds trust and eliminates awful surprises.

You need to work with a supplier who has a documented, repeatable system for everything. Quality control cannot be an afterthought. It must be integrated into every step, from inspecting the incoming aluminum ingot to the final packaging protocols. Ask potential aluminum extrusion suppliers to show you their Quality Management System documentation. Likewise, inquire about their project management. How do they track your order to guarantee it ships on time? At ALUT, every client gets a dedicated project manager who serves as a single point of contact and provides regular, scheduled updates. This systematic approach is what prevents the two biggest fears of every purchasing manager: bad quality and late delivery.

You’ve scheduled the call with a promising supplier. Now, what do you ask to get past the sales pitch? Asking generic questions will only get you generic answers. You need a better script.

As a supplier myself, I have the most respect for clients who ask tough, specific questions. You must ask about their quality control procedures, their project management workflow, and their direct experience with your industry. I believe these questions are the fastest way to determine if a company is one of the truly professional aluminum extrusion suppliers.

This initial conversation is your opportunity to conduct a verbal audit. Your goal is to uncover how they actually operate. A great supplier will welcome this level of detail because it shows you are a serious, professional buyer. To help you, I’ve grouped the most critical questions you should ask every potential aluminum extrusion supplier.

These questions confirm they have the right equipment, materials, and knowledge for your project.

These questions directly address the most common pain points: quality failures and delivery delays.

These questions clarify the commercial aspects of the partnership.

This table summarizes the key areas to probe:

| Category | Key Question to Uncover the Truth |

| Technical | What are your standard tolerances and in-house capabilities? |

| Quality | Show me your documented quality control and non-conformance process. |

| Project Management | How do you guarantee on-time delivery for my orders? |

| Comunicação | Who is my single point of contact and how do you provide updates? |

| Business | What are your terms for payment, logistics, and lead times? |

Asking these specific questions forces potential aluminum extrusion suppliers to respond with facts, not just marketing slogans. This is how you find a partner you can trust.

Finding fantastic aluminum extrusion suppliers is not about luck; it’s about a smart, disciplined process. By following these steps, you can secure a reliable partner and protect your projects.