Endereço

304 Norte Cardinal

St. Dorchester Center, MA 02124

Horas de trabalho

Segunda-feira a sexta-feira: 7h - 19h

Fim de semana: 10:00 - 17:00

Endereço

304 Norte Cardinal

St. Dorchester Center, MA 02124

Horas de trabalho

Segunda-feira a sexta-feira: 7h - 19h

Fim de semana: 10:00 - 17:00

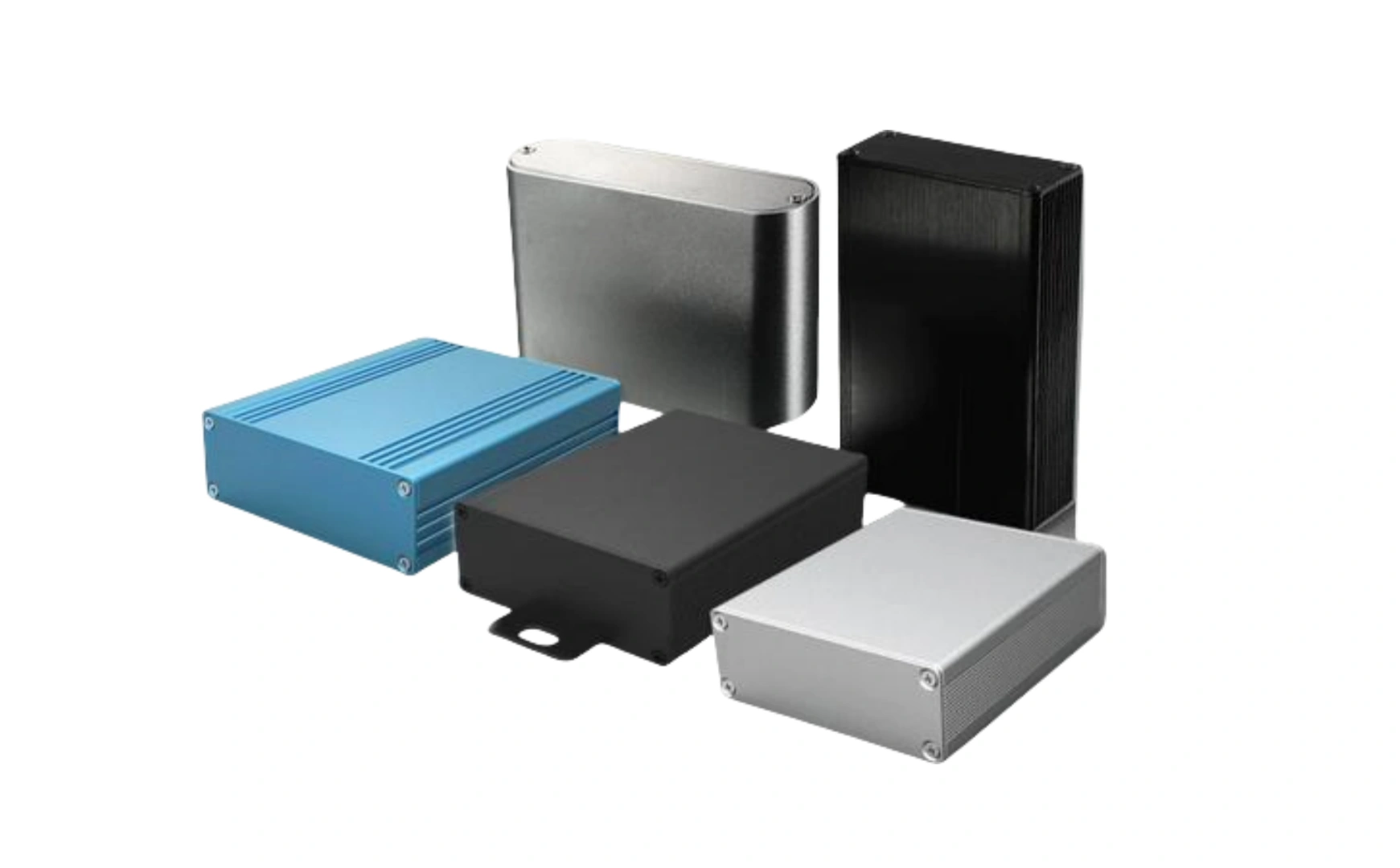

Choosing the wrong material for enclosures can cause devastating failures. This leads to costly project delays and painful rework. I’ll show you why aluminum is the superior choice for so many critical applications.

The undeniable advantages are clear: our aluminum electrical enclosures offer a fantastic combination of being lightweight, strong, naturally corrosion-resistant, and an excellent heat conductor. My team and I consistently see them outperform other materials in demanding environments, providing both durability and long-term value.

But the real question isn’t just if it’s good, but porquê and when it’s the right choice for your project. Let’s break down the technical details that matter to your bottom line.

Worried about your enclosures failing from weight stress or rust? A heavy or corroded enclosure can become a massive liability. Let’s look at why aluminum solves these specific issues so effectively.

I always advise my clients to choose aluminum electrical enclosures for their incredible strength-to-weight ratio and natural resistance to corrosion. They are significantly lighter than steel, which simplifies installation, and they form a protective oxide layer that stops rust, ensuring long-term reliability.

When an engineer or purchasing manager specifies a project, the material choice is fundamental. From my years of manufacturing high-quality aluminum electrical enclosures, I can tell you the decision to use aluminum comes down to a few key, practical advantages that impact everything from logistics to the product’s lifespan.

The primary advantage is how aluminum handles the elements. When exposed to air, aluminum instantly forms a very thin, hard layer of aluminum oxide on its surface. Unlike rust on steel, this layer is dense and bonded to the metal. This oxide layer is a natural, self-healing shield. If it gets scratched, a new protective layer forms immediately. This is why aluminum electrical enclosures can last for decades in wet or humid conditions where steel would fail.

Aluminum is about one-third the weight of steel. This is a huge benefit for aluminum electrical enclosures. Lighter weight means lower shipping costs—a direct saving. It also makes installation far easier and safer. A large steel box might require a crane, but a similar-sized aluminum electrical enclosure can often be handled by one person. Some might think “lightweight” means “weak,” but we use strong alloys like 6061-T6, which are treated for exceptional rigidity and strength.

Here is a simple breakdown of these properties:

| Imóveis | Aluminum | Carbon Steel |

| Density (Weight) | Low (Lightweight) | High (Heavy) |

| Resistência à corrosão | Excellent (Self-Protecting) | Poor (Requires Coating) |

| Relação força/peso | Muito elevado | Médio |

Electrical components generate heat, and the enclosure must dissipate it. Aluminum is an excellent thermal conductor, drawing heat away from internal components. This helps keep electronics cool and operating within their ideal temperature range. Furthermore, aluminum electrical enclosures are non-magnetic, which is critical for preventing magnetic interference with sensitive electronics.

Steel feels strong, but is it always the best option? Making an assumption can lead to unexpected failures and costs. Let’s compare them directly to see which one is truly better for your application.

In my professional experience, the ‘better’ choice depends entirely on the application. For outdoor or marine environments where corrosion is the main enemy, aluminum electrical enclosures are almost always superior. For situations needing extreme impact resistance at the lowest initial cost, steel might have an edge.

The question of aluminum versus steel is one of the most common discussions I have with clients about aluminum electrical enclosures. There is no single “better” material; there is only the “better” material for your specific project. The decision depends on the environment, budget, and performance needs. As a supplier, my job is to help you analyze these factors to make the most reliable and cost-effective choice.

Let’s put them side by side. I’ve prepared a table that my team often uses to help clients visualize the key differences. This is a crucial step in procurement because it directly links material choice to project outcomes.

| Caraterística | Aluminum Electrical Enclosures | Steel Electrical Enclosures |

| Corrosion | Naturally resistant, ideal for outdoors and wet areas. | Prone to rust. Requires paint or galvanizing. |

| Weight | Lightweight. Cheaper shipping, easier installation. | Heavy. More expensive shipping, harder installation. |

| Custo | Higher initial material cost. | Lower initial material cost. |

| Condutividade | Excellent heat dissipation. Non-magnetic. | Poor heat dissipation. Magnetic. |

| Modification | Easy to cut, drill, and machine. | Harder to machine. Requires more powerful tools. |

| Durability | Long lifespan, especially outdoors. | Can be very strong but lifespan depends on coating. |

A purchasing manager often focuses on the initial price, and steel is usually cheaper per kilogram. However, this is a shortsighted view. We encourage our clients to consider the Total Cost of Ownership (TCO). An aluminum electrical enclosure might cost more initially but saves money over its lifetime. You save on shipping, labor, and most importantly, on maintenance and replacement because it won’t fail from rust. A steel box near the ocean might need replacement in 5-10 years, while our aluminum electrical enclosures could last for 25 years or more.

Placing sensitive electronics outdoors is a major risk. The weather can destroy expensive equipment very quickly. You need an enclosure you can absolutely trust to protect your investment from the elements.

Yes, absolutely. I have supplied countless aluminum electrical enclosures for the most demanding outdoor projects. Their natural corrosion resistance makes them perfect for rain, humidity, and even salty marine air. When we build them to the correct NEMA or IP rating, they provide outstanding, long-lasting protection.

Outdoor installations are the ultimate test for any enclosure. The unit must fight off rain, snow, dust, UV radiation, and extreme temperature swings. This is where the material properties of aluminum truly excel, and why so many of our clients in the telecom, solar, and infrastructure sectors specify aluminum electrical enclosures for their projects.

The suitability of an enclosure for outdoor use is defined by its NEMA or IP rating. These ratings certify how well the box is sealed against dust and water ingress.

Here is a quick guide to common outdoor NEMA ratings for our aluminum electrical enclosures:

| NEMA Rating | Protection Against | Typical Use Case |

| NEMA 3R | Rain, sleet, snow, and external ice formation. | Outdoor wiring boxes, utility meters. |

| NEMA 4 | Same as 3R, plus windblown dust and hose-directed water. | Industrial washdown areas, general outdoor use. |

| NEMA 4X | Same as 4, plus corrosion resistance. | Marine environments, wastewater plants, coastal areas. |

An aluminum electrical enclosure is the perfect base material for a NEMA 4X rating. Because the aluminum itself is corrosion-resistant (the “X” in 4X), you don’t have to worry about a paint or coating failure causing rust. This is a common point of failure for coated steel enclosures.

Another outdoor enemy is the sun. UV radiation can degrade paints and break down plastics. We often provide our aluminum electrical enclosures with a durable powder coat finish. This adds a layer of UV protection and allows for color matching. Furthermore, aluminum’s high thermal conductivity helps stabilize the internal temperature, protecting the electronics inside from extreme temperature cycles.

Electrical safety is not negotiable. An improper ground can lead to equipment failure or a fatal accident. This is a simple question with a critical answer you must know.

Yes, and you absolutely must ground it. It is a critical safety requirement. We always provide a dedicated grounding stud or lug in our aluminum electrical enclosures. This ensures a secure, reliable connection to the system ground, protecting both people and equipment from electrical faults.

This question is vital because it relates directly to safety and proper installation. Any metal electrical enclosure, regardless of material, must be grounded. Grounding provides a safe path for electrical current to flow to the earth in the event of a fault. Without a proper ground on your aluminum electrical enclosure, the entire metal box could become energized, creating a lethal shock hazard.

In our factory, every aluminum electrical enclosure we produce is designed with grounding as a priority. We typically weld or press a dedicated grounding stud onto the inside of the box or its backplate. This provides a secure point for the ground wire.

The correct procedure is simple but must be followed:

The most common mistake we see is relying on mounting screws or door hinges to provide a ground path. These are not reliable connections. Another mistake is failing to remove the paint from the connection point. An aluminum electrical enclosure is an exceptionally safe product, but only when it is installed correctly.

In short, aluminum electrical enclosures offer an undeniable mix of lightness, strength, and long-term durability. For your next project, consider how these critical advantages align with your requirements for performance and reliability.