Endereço

304 Norte Cardinal

St. Dorchester Center, MA 02124

Horas de trabalho

Segunda-feira a sexta-feira: 7h - 19h

Fim de semana: 10:00 - 17:00

Endereço

304 Norte Cardinal

St. Dorchester Center, MA 02124

Horas de trabalho

Segunda-feira a sexta-feira: 7h - 19h

Fim de semana: 10:00 - 17:00

Struggling with materials that are too heavy or weak for your designs? This can cause project failures and budget overruns. I’ve found that a specific process provides a powerful, reliable solution.

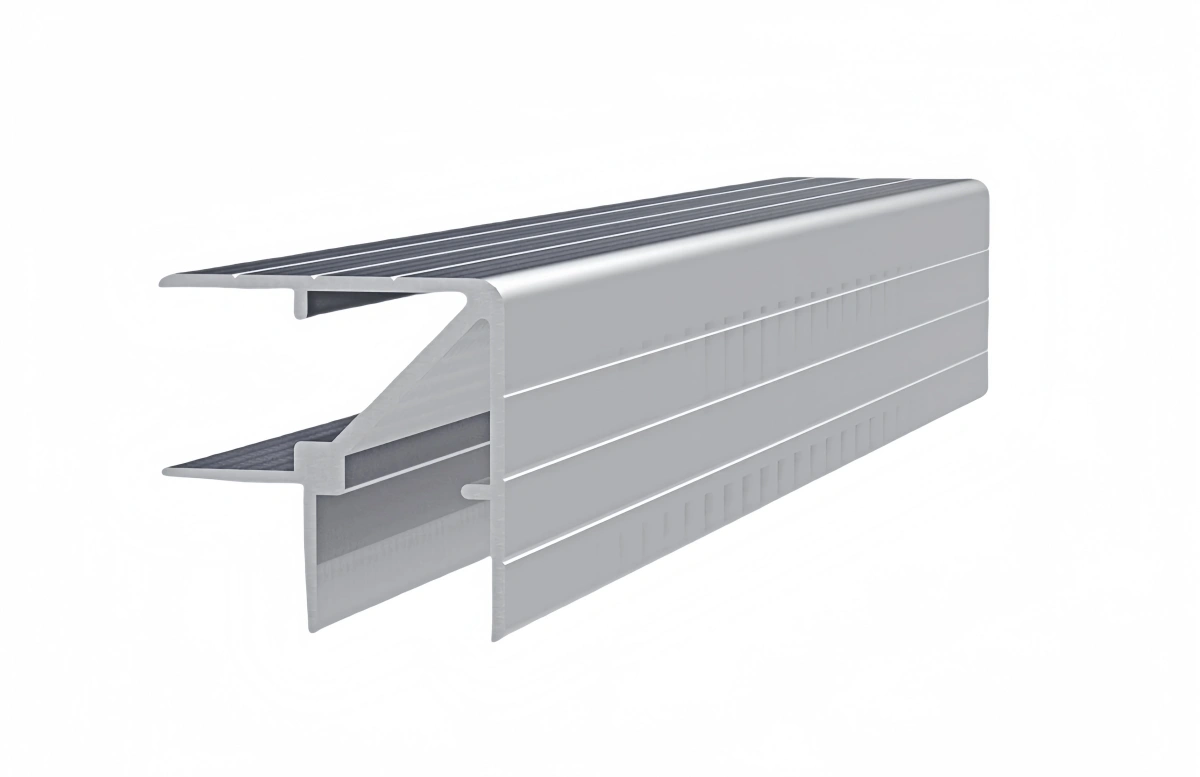

From my perspective, the secret lies in its unmatched combination of light weight, high strength, and incredible design flexibility. I’ve seen firsthand how an aluminum angle extrusion allows us to create complex, durable parts that are both cost-effective and perfect for high-performance applications.

This unique blend of properties makes it a superior choice for a huge range of products. But what are the specific benefits that make it so valuable? Let’s break it down.

Are you trying to reduce project costs and overall product weight? These factors can eat into your profit margins and create logistical headaches. I’ve learned that focusing on the right material from the start solves this.

In my experience, the most important benefits I explain to clients are its high strength-to-weight ratio, excellent natural corrosion resistance, and long-term cost-effectiveness. These three advantages make aluminum angle extrusion a smarter choice than steel or other materials for many projects.

The benefits of this material go beyond a simple list; they directly impact your project’s success and your bottom line. When I work with purchasing managers like you, the conversation always comes back to how these features solve real-world problems.

One of the first things you’ll notice about an aluminum angle extrusion is how light it is. But don’t let that fool you. Certain aluminum alloys, when extruded, are incredibly strong. This high strength-to-weight ratio is a game-changer. For your company, this means:

I remember a project for a client who manufactured automated warehouse systems. By switching from steel frames to an aluminum angle extrusion design, they not only reduced the weight of each unit by 40% but also improved the speed and energy efficiency of the robots.

Another major pain point I often hear about is long-term durability, especially for products used outdoors or in harsh environments. Steel rusts. Aluminum, on the other hand, creates its own protective layer. When aluminum is exposed to air, it instantly forms a thin, tough layer of aluminum oxide on its surface. This layer is highly resistant to corrosion. It prevents rust and degradation without needing expensive coatings like paint or galvanization, though we can provide those for aesthetic or extra protection. This means your final product will last longer and require less maintenance, enhancing your brand’s reputation for quality.

While raw material costs fluctuate, the aluminum extrusion process itself is highly efficient. The initial investment in a custom die is often much lower than the tooling costs for casting or other fabrication methods. Because the die can be used to produce thousands of identical parts, the per-unit cost drops significantly on larger wholesale orders. This process allows us to create a consistent, reliable aluminum angle extrusion profile every single time, which is critical for your assembly lines.

Have you ever received a shipment of parts where the dimensions were inconsistent? I know this can halt a production line and cause massive delays, a problem no purchasing manager wants to face. I believe that understanding how parts are made is the first step to ensuring quality.

From my factory floor, I can tell you the process is beautifully simple and precise. We start by heating a solid aluminum log, called a billet, to a specific temperature. Then, we use a powerful hydraulic press to force the softened aluminum through a shaped steel die. It’s like squeezing toothpaste from a tube, creating a perfect, continuous aluminum angle extrusion.

A deep understanding of this process is what separates a reliable supplier from one that causes problems. At ALUT, our control over each step is how we prevent the quality issues that I know are a major pain point for you. A slight deviation in temperature or pressure can compromise the entire batch, leading to parts that don’t meet your specifications. That’s why our process control is so strict.

The journey is more than just a simple push. It’s a carefully controlled sequence of events that we have perfected over the years. Each step is critical for ensuring the final aluminum angle extrusion meets your exact dimensional tolerances and structural requirements.

Here is a simplified breakdown of our process:

| Step Number | Process Stage | Why It’s Critical for Quality |

| 1 | Die Design & Production | The die is the blueprint. Its precision determines the final shape and tolerances of your part. |

| 2 | Billet Heating | The billet must be heated to the exact temperature (around 400-500°C) for its alloy. Too hot or cold affects the final grain structure and strength. |

| 3 | Extrusão | The softened billet is forced through the die. We control the speed to ensure a smooth surface finish. |

| 4 | Cooling (Quenching) | The profile is cooled rapidly. This locks in the material properties and is a key part of the heat-treating process. |

| 5 | Stretching & Straightening | The profile is stretched to relieve internal stress and correct any minor twisting, ensuring it’s perfectly straight. |

| 6 | Cutting & Finishing | The extrusion is cut to your specified lengths. Additional finishing like anodizing or powder coating can be applied here. |

Your biggest fear—receiving out-of-spec parts—stems from a supplier’s failure in one of these stages. For example, if the billet in Step 2 is overheated, the material becomes brittle. If the cooling in Step 4 is uneven, the profile can warp. This is why our on-site quality control team monitors every stage. We don’t just inspect the final product; we manage the process. This integrated approach, from die design to logistics, ensures that the aluminum angle extrusion you receive is exactly what you ordered. It saves you time, money, and the stress of production delays.

Are you concerned about choosing the wrong material specification for a new product? I’ve seen how a poor choice here can lead to product failure, which damages not just the product but also your company’s reputation. I always tell my clients that a successful project begins with selecting the right alloy.

In my daily work, I find that we use the 6000 series of alloys for the vast majority of projects. Specifically, 6061 and 6063 alloys are the workhorses. They provide an excellent balance of strength, corrosion resistance, and surface finish, making them ideal for an aluminum angle extrusion.

Choosing between alloys isn’t an academic exercise; it’s a practical decision that directly affects your product’s performance and cost. A supplier’s sales representative who lacks this professional knowledge can cause major issues. My team and I focus on understanding your application first, so we can provide a concise, professional recommendation. This is a core part of the service we provide.

The 6000 series alloys, with magnesium and silicon as their main alloying elements, are popular for a reason. They are highly versatile and respond well to heat treatment, which allows us to adjust their final strength.

I had a client who was developing a new line of high-end office furniture. They initially specified 6061 for the leg frames. After discussing the application, I recommended 6063 instead. It provided more than enough strength for the furniture, but its superior finish meant they could achieve a premium look with a simple anodizing process, saving them the cost of an extra polishing step. This is the kind of professional input that prevents costly over-engineering.

To make it simpler, here is a table that breaks down the key differences. This is the kind of clear information I like to provide to help you make a fast, informed decision.

| Liga metálica | Main Characteristics | Melhor para... |

| 6061 | High strength, good weldability, good corrosion resistance. | Structural applications, machinery, platforms, transportation. |

| 6063 | Excellent surface finish, good corrosion resistance, good for complex shapes. | Architectural trim, window/door frames, electronic housings. |

| 7075 | Extremely high strength, like steel. | High-stress aerospace or sporting goods parts. Not for welding. |

Are you wondering if an aluminum angle extrusion is a practical fit for your specific product line? I understand that making the wrong material choice is a mistake that can cost you both time and money. Let me show you just how versatile this product truly is.

From my factory’s production history, I can tell you the applications are almost endless. We produce aluminum angle extrusion for structural frames in industrial automation, sleek housings for LED lighting products, support brackets for solar panels, and clean-finish trim for architectural projects. Its versatility is its greatest asset.

The reason for this wide range of uses goes back to the core benefits we discussed: strength, light weight, durability, and design flexibility. When you are importing parts to assemble into your final products, like LED lights or industrial machines, choosing a material that can do many things well simplifies your supply chain. You can often use different profiles made from the same aluminum angle extrusion process across multiple product lines.

Seeing where and why this material is used can help you identify opportunities in your own product development. We frequently see it in three main sectors.

This is a huge area for us. In factories and warehouses, the aluminum angle extrusion is a building block for efficiency and safety.

The excellent surface finish of 6063 alloy makes it a favorite among architects and builders.

This is a growing market for our clients who assemble finished goods.

This table summarizes why it’s chosen for each area:

| Application Area | Specific Example | Key Reason for Using Aluminum Angle Extrusion |

| Industrial | Automated Machine Frame | High strength-to-weight ratio, easy assembly |

| Construction | Solar Panel Mounting Frame | Corrosion resistance, long-term durability |

| Electronics | LED Light Housing | Excellent heat dissipation, premium finish |

Ultimately, an aluminum angle extrusion provides a powerful mix of strength, versatility, and value. Understanding the process and materials is key to getting the flawless, reliable parts your projects demand.