Endereço

304 Norte Cardinal

St. Dorchester Center, MA 02124

Horas de trabalho

Segunda-feira a sexta-feira: 7h - 19h

Fim de semana: 10:00 - 17:00

Endereço

304 Norte Cardinal

St. Dorchester Center, MA 02124

Horas de trabalho

Segunda-feira a sexta-feira: 7h - 19h

Fim de semana: 10:00 - 17:00

Struggling with parts that are too heavy or not strong enough? This single issue can compromise your entire product design. I’ve learned that the right profile is the key.

From my two decades in this business, I can tell you the secret lies in their incredible versatility. Aluminum channel extrusions deliver the perfect mix of high strength, low weight, and nearly unlimited design freedom, which is why they are essential for superior product development.

This unique combination is a game-changer for many industries. But to truly leverage these benefits, you need to understand the details. Let’s explore this further. We will look at how they are made, their key benefits, the different types, and most importantly, how to choose the best aluminum channel extrusions for your project.

Ever received a shipment of parts that didn’t meet the design specifications? It creates massive delays and costs you money. Understanding the manufacturing process helps you choose a reliable supplier.

I’ve overseen thousands of production runs at our factory. In simple terms, we take a solid aluminum cylinder, called a billet, heat it to around 500°C, and then use immense pressure to force it through a specially shaped steel die. It’s very much like squeezing toothpaste from a tube, creating a perfect, continuous profile.

The manufacturing of aluminum channel extrusions is a precise science. When a client’s project depends on parts fitting together perfectly, there is no room for error. The quality of the final product is determined by several critical stages, each requiring expert oversight. It’s a process we’ve refined over many years to eliminate the common problems that purchasing managers face, like receiving out-of-spec parts.

The journey from a raw aluminum log to a finished profile involves several key steps. It’s more than just pushing metal through a hole; it’s a controlled industrial process.

The die is the heart of the extrusion process. A poorly designed die for aluminum channel extrusions is often the root cause of dimensional tolerance issues. As a purchasing manager, you’ve likely experienced the frustration of parts not fitting. This often comes down to the supplier’s expertise in die making. A well-designed die accounts for how the aluminum will flow under pressure and heat, ensuring the final aluminum channel extrusions meet the exact dimensions specified in your drawings. This is where a supplier’s engineering capability truly shows.

Raw, or “mill finish,” aluminum channel extrusions are not always the final product. Many applications require a surface finish for cosmetic appeal or extra protection.

| Finishing Type | Descrição | Key Benefits |

| Anodização | An electrochemical process that creates a hard, durable oxide layer on the surface. | Excellent corrosion and wear resistance; can be dyed in various colors. |

| Revestimento em pó | A dry powder is applied electrostatically and then cured under heat. | Provides a very durable, uniform, and attractive finish in a vast range of colors. |

| Mill Finish | The natural finish of the aluminum as it comes out of the extrusion process. | Lowest cost option; suitable for applications where appearance is not critical. |

Understanding these steps helps you ask the right questions and identify a supplier who has control over their process, ensuring you receive high-quality aluminum channel extrusions every time.

Are high material costs and excess weight making your products less competitive? This can directly impact your bottom line and market position. These profiles offer a powerful and cost-effective solution.

I always tell my clients that the two biggest benefits are the amazing strength-to-weight ratio and the incredible design flexibility. In my experience, this means you get a very strong part that is also lightweight and can be shaped perfectly for your specific product, which is a huge advantage.

For a purchasing manager, the benefits of aluminum channel extrusions translate directly into solving common procurement challenges. You need components that are reliable, cost-effective, and contribute to a better final product. These extrusions check all those boxes. They are not just a piece of metal; they are an engineered solution. The properties of aluminum, combined with the efficiency of the extrusion process, create a value proposition that is hard to beat, especially when compared to other materials and manufacturing methods like steel fabrication or plastic molding.

This is the most famous benefit. Aluminum is about one-third the weight of steel. This is a massive advantage. Lighter products are cheaper to ship, which is a significant cost factor in international logistics. They are also easier to handle and assemble, which can speed up your production lines. But light weight does not mean weak. Through proper alloy selection and temper treatment (like the T6 temper), aluminum channel extrusions can be made strong enough for structural applications, from window frames to machine chassis.

Aluminum naturally creates a thin, protective oxide layer when exposed to air. This layer is passive and prevents the metal from rusting like steel does. This inherent resistance makes aluminum channel extrusions ideal for products used outdoors or in humid environments, like lighting fixtures or electronic enclosures. For even greater protection, surface treatments like anodizing can be applied, creating a surface that is almost as hard as diamond and extremely resistant to corrosion. This reduces long-term warranty claims and increases customer satisfaction.

Aluminum is an excellent conductor of both heat and electricity. It’s about twice as conductive as steel. This property makes aluminum channel extrusions a perfect choice for applications that need to manage heat, such as LED light heat sinks or housings for electronic components. The ability to design complex fins directly into aluminum channel extrusions maximizes surface area, allowing for highly efficient passive cooling. This saves you the cost and complexity of adding separate heat sink components.

| Imóveis | Aluminum (6061 Alloy) | Mild Steel |

| Density | ~2.70 g/cm³ | ~7.85 g/cm³ |

| Relação força/peso | Elevado | Médio |

| Resistência à corrosão | Excelente | Poor (rusts) |

| Thermal Conductivity | Elevado | Baixa |

This unique combination of benefits ensures that using aluminum channel extrusions can lead to a better, more reliable, and more cost-effective final product.

Are you feeling confused by all the different profile shapes you see online? Choosing the wrong profile type can lead to a component that fails or doesn’t fit, causing a project-killing delay.

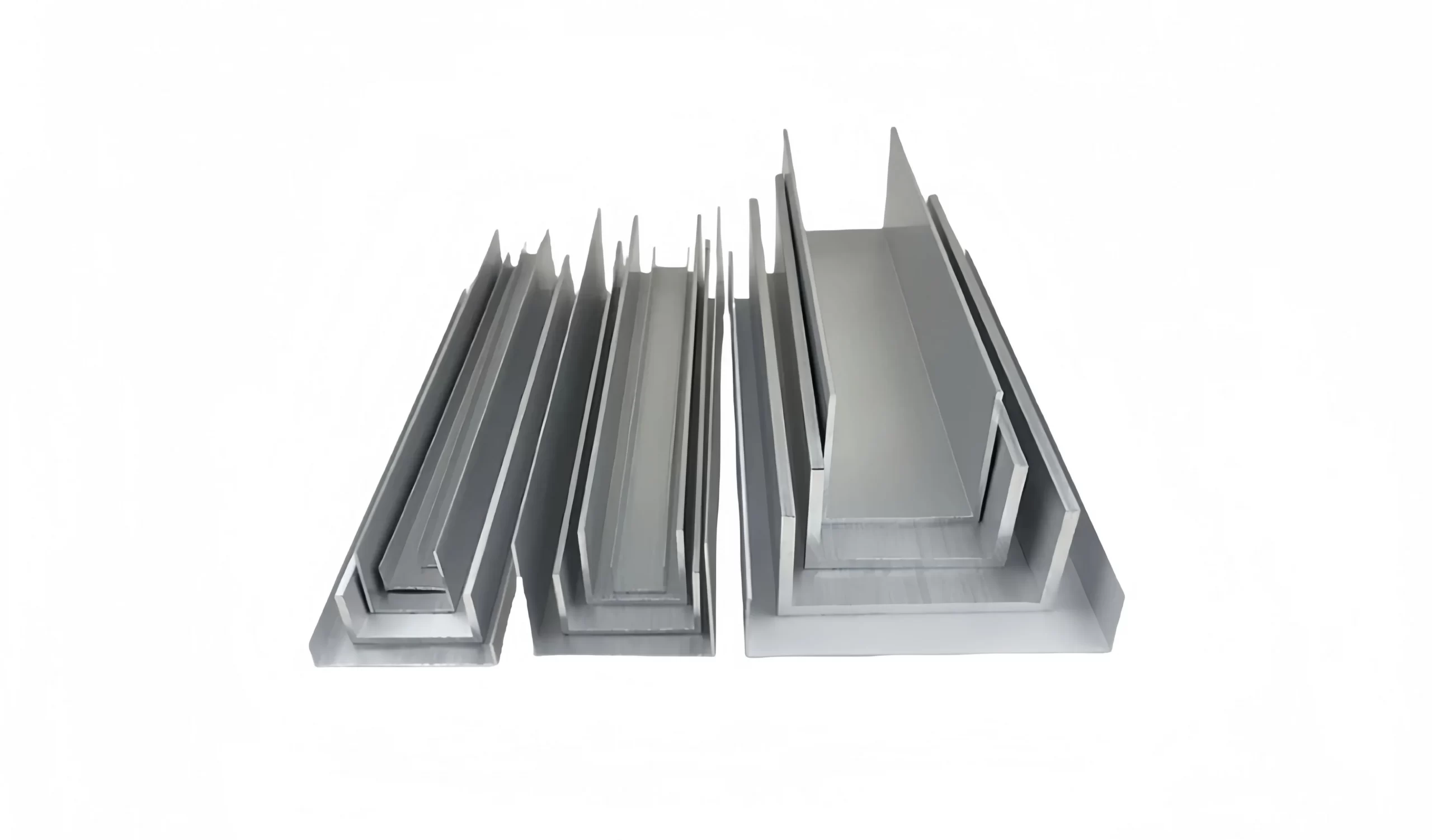

In my experience helping clients, I find that while we can create almost any custom shape imaginable, most projects start with standard profiles. These include C-channels, U-channels, and T-slots. We often use these as a base and then modify them to meet the client’s exact needs.

The term “aluminum channel extrusions” covers a huge variety of shapes. This variety is one of the greatest strengths of the process, but it can also be a source of confusion. As a purchasing manager, your primary goal is to source a part that performs its function perfectly. The key is to understand that you are not limited to what you see in a catalog. The process for creating aluminum channel extrusions is built for customization. A good supplier will not just sell you a standard part; they will work with you to provide the perfect profile for your application, whether it’s a slight modification of a standard shape or a completely unique, custom design.

Standard shapes for aluminum channel extrusions are widely used across many industries because they serve common structural and architectural functions. They are often available more quickly because the dies for them already exist.

This is where the true power of aluminum channel extrusions lies. The extrusion process allows for the creation of very complex cross-sections that can be tailored to a specific function. We can design profiles that incorporate multiple features into a single piece. This has huge benefits:

| Channel Type | Primary Feature | Aplicações comuns |

| U-Channel | Simple open channel | Edging, tracks, protective trim |

| C-Channel | Added rigidity from lips | Structural frames, brackets, supports |

| T-Slot Channel | Modular connection slot | Machine guarding, workstations, automation frames |

Ultimately, whether you need a standard profile or a fully custom design, the possibilities with aluminum channel extrusions are nearly endless.

Are you worried about making the wrong procurement decision? A bad choice here can lead to a lot of wasted time, money, and stressful conversations with your engineering team.

I always advise my customers to start by clearly defining their application’s load requirements and its operating environment. In my years of project management, I’ve seen that this one step—getting the requirements right at the start—helps narrow down the alloy, temper, and profile shape, preventing almost all costly mistakes later on.

Selecting the correct aluminum channel extrusions is a critical decision that impacts product performance, cost, and reliability. As a purchasing manager, you are at the center of this decision, balancing the technical requirements from your engineers with the cost and supply chain realities. It’s not just about finding the cheapest part; it’s about securing the best value and ensuring the component will not fail. A supplier should act as a partner in this process, using their expertise to guide you to the optimal solution. This avoids the pain points of receiving parts with insufficient strength or the wrong finish.

First, you must be very clear about what the aluminum channel extrusions will do.

Not all aluminum is the same. There are many different alloys, and each has different properties. The two most common alloys for aluminum channel extrusions are 6061 and 6063.

The “temper,” such as T5 or T6, refers to the heat treatment process and determines the final strength and hardness. T6 is stronger than T5.

This is where communication with your supplier is key. You must clearly specify the required dimensional tolerances. If parts need to fit together with high precision, you will need tighter tolerances. A capable supplier can hold these tolerances consistently, which prevents assembly problems. You also need to specify the finish. Do you need it anodized for corrosion resistance? Powder coated for a specific color? Or is a simple mill finish acceptable? Making these decisions early prevents delays and ensures the final aluminum channel extrusions meet all your requirements.

Choosing the right supplier for your aluminum channel extrusions is a critical step. By understanding the manufacturing, benefits, types, and selection criteria, you can make an informed decision for success.