주소

304 북쪽 추기경

세인트 도체스터 센터, MA 02124

근무 시간

월요일~금요일: 오전 7시~오후 7시

주말: 주말: 오전 10시 - 오후 5시

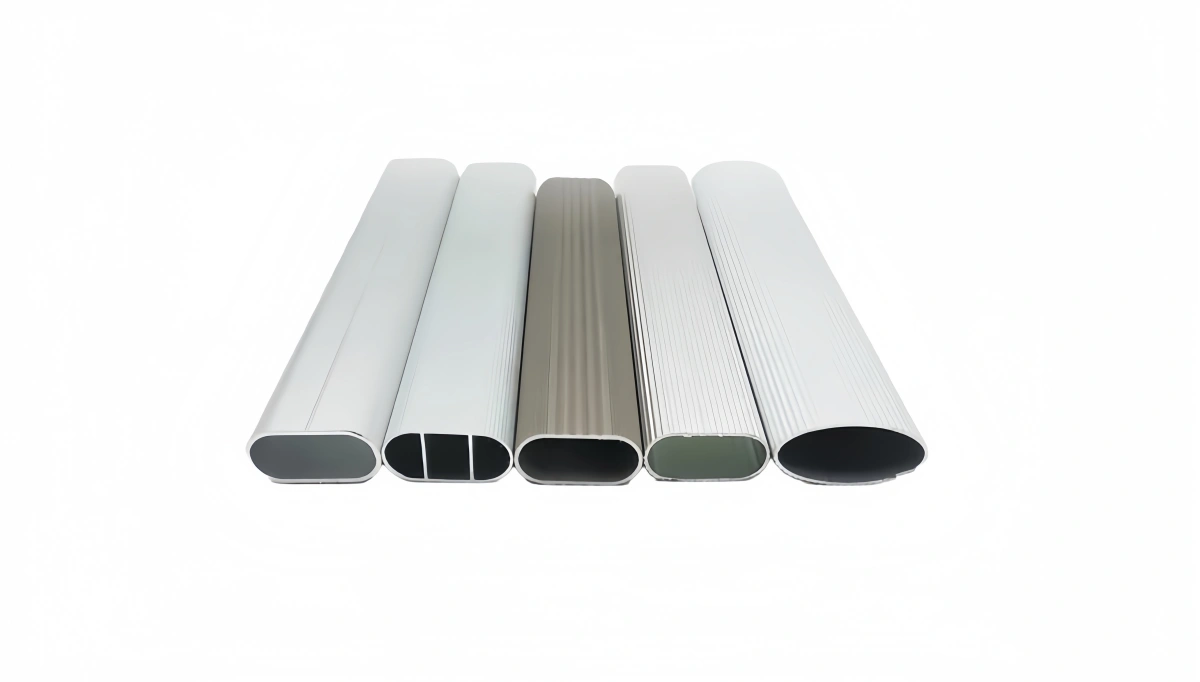

I often get asked, “What’s the big deal about oval aluminum extrusion?” As someone who lives and breathes custom aluminum, I see incredible value. Let’s explore why this shape is so powerful.

Oval aluminum extrusion is a specialized profile. It offers a unique blend of strength, aesthetics, and functionality. We use it across many industries. This includes automotive, architecture, and lighting. Its distinct shape provides advantages over traditional round or square extrusions. It helps in both design and performance.

Stay with me as we uncover the surprising ways oval aluminum extrusion can improve your projects. You might find exactly what you need.

I’ve seen firsthand how versatile oval aluminum extrusion can be. What might seem like a simple shape actually solves complex design challenges.

Oval aluminum extrusion has many common uses. It is found in architectural trim, automotive parts, and LED lighting fixtures. You can also see it in furniture components, machinery guards, and display systems. Its unique shape makes it ideal for both structural and aesthetic applications across diverse industries.

Oval aluminum extrusion serves a wide range of applications. Its unique shape provides benefits where other profiles might fall short. For example, in architecture, oval extrusions are often used for decorative trim. They also work well for handrails or window frames. Their smooth, curved surfaces can add a modern look to buildings. This makes them popular with designers.

In the automotive industry, oval aluminum extrusion is important. Car manufacturers use it for structural components. This includes chassis elements or specialized brackets. The shape allows for good strength-to-weight ratios. This is crucial for fuel efficiency. It also helps in protecting passengers. Sometimes, you see it in the interior of vehicles. It might be part of the dashboard or door panels. Its aesthetic appeal makes it a good choice there.

LED lighting is another big area for oval aluminum extrusion. These extrusions act as housings for LED strips. The oval shape helps with heat dissipation. This makes the LED lights last longer. It also provides a sleek and modern look for the light fixtures. You find these in offices, retail stores, and even homes. They are popular for both recessed and surface-mounted lights.

Here is a simple table showing some common applications:

| 산업 | Common Uses of Oval Aluminum Extrusion |

| Architecture | Decorative trim, handrails, window frames, facade elements |

| 자동차 | Structural components, interior trim, bumper supports |

| Lighting | LED light housings, heat sinks, lamp bodies |

| Furniture | Table legs, chair frames, display stands |

| Industrial | Machine guards, conveyor system components, automation parts |

Beyond these, oval aluminum extrusion appears in consumer goods. It is used in sporting equipment or even specialized electronics enclosures. The ability to customize the size and wall thickness makes it adaptable. This means it can fit many different needs. Our factory produces these custom shapes regularly. We work with clients to get the exact profile they need. This flexibility is a key reason for its widespread use. It allows for innovative design solutions that are both functional and visually appealing. The demand for these custom profiles continues to grow as industries look for better materials.

I remember visiting our factory in China and seeing the extrusion process firsthand. It’s truly impressive to witness how a simple billet transforms into a complex oval aluminum extrusion. It made me think, “How do they get that perfect shape every time?”

Oval aluminum extrusion is made through a process called hot extrusion. A heated aluminum billet, or log, is pushed through a die. This die has the desired oval shape. High pressure forces the soft aluminum to flow out of the die opening. It comes out as a continuous oval profile. This process allows for complex shapes and precise dimensions.

The manufacturing of oval aluminum extrusion begins with an aluminum billet. This billet is a solid, cylindrical piece of aluminum. First, we heat this billet in a furnace. This makes the aluminum soft and pliable. The temperature is important. It needs to be hot enough to flow but not so hot that it melts. Usually, temperatures range from 450°C to 500°C (850°F to 930°F).

Next, we load the heated billet into the extrusion press. The press has a ram that pushes the billet. It pushes the billet towards a die. The die is a special tool with a precisely cut opening. This opening has the exact oval shape we want for the finished product. The pressure from the ram is very high. It can be thousands of tons. This pressure forces the soft aluminum through the die opening.

As the aluminum exits the die, it takes on the oval shape. This is the extrusion. It comes out as a long, continuous profile. We call this the “extruded profile.” Right after it exits, we cool the oval aluminum extrusion. This is often done with water or air. Cooling helps to strengthen the aluminum. It also sets the final shape.

After cooling, the long oval aluminum extrusion is stretched. This stretching step is called “stretching.” It helps to remove any twists or bends that happened during extrusion. It also improves the straightness of the profile. This is crucial for maintaining tight tolerances.

Finally, we cut the long oval aluminum extrusion into desired lengths. This is done using a saw. Sometimes, further operations happen. These might include heat treatment to improve strength. We might also do machining. This adds holes or other features. Our factory in China uses advanced machines for all these steps. This ensures high quality and precision for every oval aluminum extrusion we make.

Here is a summary of the main steps in the extrusion process:

This careful process ensures that each oval aluminum extrusion meets strict quality standards. This includes the precise dimensions and surface finish that customers expect.

As someone deeply involved in supplying customized aluminum products, I often highlight the advantages of specific profiles. When I explain the benefits of oval aluminum extrusion, clients quickly understand why it’s a superior choice for many applications.

Using oval aluminum profiles offers many benefits. These include superior strength-to-weight ratio and improved aesthetics. They also provide better air flow in some designs. The shape helps with thermal management. It is also easy to clean. Oval aluminum extrusion offers design flexibility. This makes it a great choice for many different products.

Oval aluminum profiles come with several key advantages that make them a preferred choice in many industries. One major benefit is their excellent strength-to-weight ratio. Aluminum is already a lightweight metal. When formed into an oval shape, it can achieve good structural integrity without adding much weight. This is important for things like automotive parts or aerospace components. Reduced weight means better fuel efficiency and lower shipping costs.

Another significant benefit is improved aesthetics. The smooth, curved lines of an oval aluminum extrusion offer a modern and sleek appearance. This is often more pleasing than sharp corners of square or rectangular profiles. This makes them popular for visible components. You see them in furniture, display systems, and architectural features. They can give products a more refined look.

Oval shapes also offer advantages in specific functional areas. For example, in applications where air or fluid flow is important, an oval shape can be more aerodynamic than a square. This can reduce drag or improve efficiency. This is valuable in certain machinery or ventilation systems. For heat management, the surface area of an oval can be optimized. This helps dissipate heat more effectively. This is why it is used in LED light housings.

Design flexibility is a powerful advantage of oval aluminum extrusion. The extrusion process allows for tight tolerances and complex internal features. This means you can integrate channels for wiring or mounting points directly into the profile. This simplifies assembly and reduces the need for additional parts. Engineers can create custom oval profiles to meet very specific design requirements. This makes ALUT a great partner for custom solutions.

Here is a comparison highlighting some benefits:

| 기능 | Oval Aluminum Extrusion Benefits |

| Strength-to-Weight | High, for lightweight yet strong structures |

| Aesthetics | Modern, sleek, and visually appealing curves |

| Aerodynamics | Can improve airflow in certain applications |

| Thermal Management | Optimized surface area for heat dissipation |

| 디자인 유연성 | Allows for complex internal features and custom shapes |

| 내식성 | Inherently good, as with all aluminum extrusions |

| Ease of Cleaning | Smooth surfaces are easier to maintain |

These benefits make oval aluminum extrusion a practical and efficient choice. They meet both performance and aesthetic needs. We focus on delivering products that leverage these advantages fully.

When choosing an aluminum profile, clients often ask me to compare shapes. “Why an oval, Wilson, when I can use round or square?” I always explain how oval aluminum extrusion offers unique advantages over more common profiles.

Oval aluminum extrusion compares favorably to round or square profiles. It often offers a better strength-to-weight ratio than round in some directions. It provides a sleeker aesthetic than square. Oval shapes are good for specific aerodynamic or ergonomic needs. They also allow for more internal space than a round profile of similar overall dimensions. This makes them a distinct choice.

Comparing oval aluminum extrusion to round or square profiles reveals distinct differences. Each shape has its own set of advantages and disadvantages. The best choice depends on the specific application.

Round aluminum extrusions are very strong against twisting forces (torsion). They also have a uniform appearance from all angles. This makes them good for poles or pipes where forces are evenly distributed. However, round profiles can take up more space for a given internal area. They also might not offer the same directional strength as an oval. For example, an oval might be stronger along its longer axis than a round tube with the same overall diameter.

Square or rectangular aluminum extrusions are excellent for structural frames. They are easy to connect and bolt together. They provide flat surfaces for mounting components. Their straight edges are good for aligning with other parts. However, square profiles can be heavier for the same strength as an optimized oval. They also lack the smooth aesthetic of an oval. Their sharp corners might not be ideal for certain ergonomic or safety applications. In addition, square shapes can be less aerodynamic than an oval. This is important when air flow is a concern.

Oval aluminum extrusion sits between these two. It offers some of the best qualities of both. For instance, an oval can provide a larger internal volume than a round tube of similar overall width. This is useful for running cables or pipes. It can also be more rigid in one direction, like a rectangle, but with the smooth curves of a round tube. This makes it good for beams that need strength in a specific plane. The aesthetics are also a major factor. The soft curves of an oval often look more modern and less industrial than a square.

Here is a comparison table to summarize:

| 기능 | Round Aluminum | Square Aluminum | Oval Aluminum Extrusion |

| Strength (Torsion) | 우수 | Good | Good (directional) |

| Strength (Bending) | Uniform | Directional | Directional (can be optimized) |

| Aesthetics | Classic, simple | Industrial, functional | Modern, sleek, aerodynamic |

| Space Efficiency | Can be less efficient internally | Good for stacking, flat surfaces | Can offer more internal volume than round |

| Mounting | Requires clamps | Easy, flat surfaces | Requires custom fittings or creative solutions |

| 애플리케이션 | Pipes, poles, railings | Frames, structural supports, enclosures | Decorative trim, heat sinks, ergonomic handles, specialized structures |

Ultimately, the choice comes down to specific needs. If you need uniform strength in all directions, round is good. If you need easy connections and flat surfaces, square works well. But if you need a blend of aesthetics, directional strength, and good internal space, oval aluminum extrusion is often the superior choice. My team and I help clients decide which shape best fits their project.

Oval aluminum extrusion is a powerful and flexible material. It offers unique benefits in many industries. It is often a better choice than round or square profiles. Consider its advantages for your next project.

Name: Wilson Yau

이메일: [email protected]

Website: https://www.lt-aluminum.com

Brand name: ALUT

Country: China

Products: customized aluminum products

Business model: B2B, wholesale only. We are our factory with an area of more than 10,000 square meters, with factories in China. Customers place orders with us, and our service team provides complete supply chain services, including order management, quality control, and logistics management.