주소

304 북쪽 추기경

세인트 도체스터 센터, MA 02124

근무 시간

월요일~금요일: 오전 7시~오후 7시

주말: 주말: 오전 10시 - 오후 5시

I’ve seen firsthand how challenging it can be to find the right materials for complex projects. Many struggle with material limitations. What if I told you there’s an amazing solution that could solve many of your design problems?

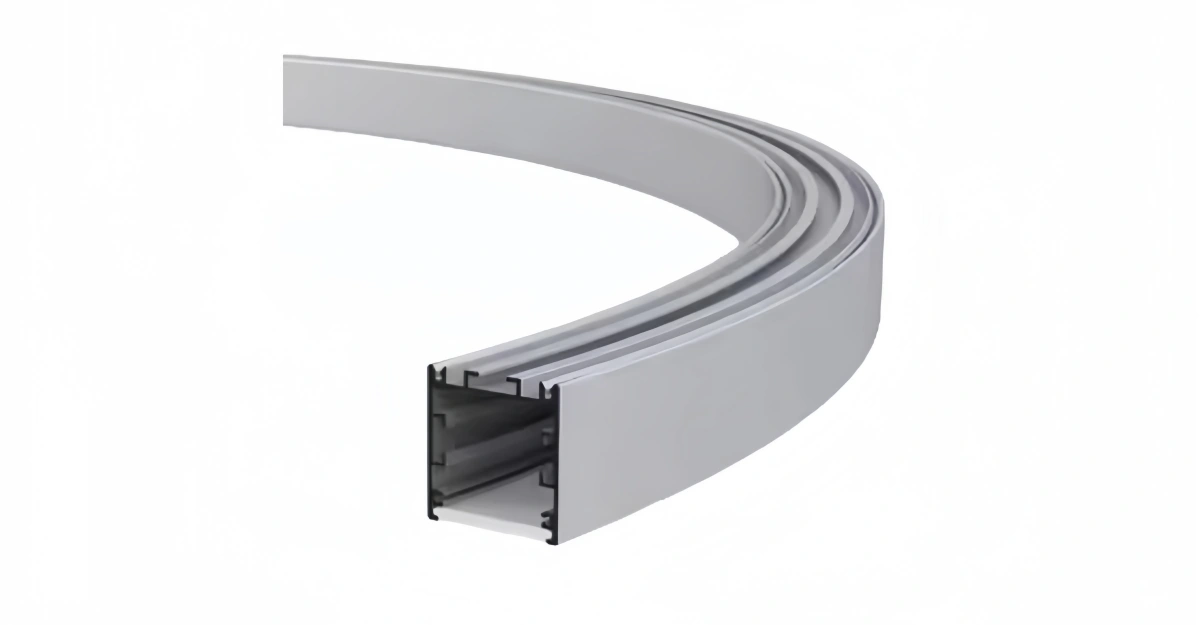

Curved aluminum extrusions are specially shaped metal pieces. They are made by pushing aluminum through a die, then bending it into curves. These parts are often used in building, transport, and product design. This process makes strong and light parts.

Stay with me as we explore how these incredible parts can change your projects for the better.

I often hear people ask how these unique parts fit into real-world applications. It’s a common question, and I understand why it comes up.

Curved aluminum extrusions have many uses. They are found in modern architecture for building facades and skylights. The automotive industry uses them for vehicle frames and interior trims. Furniture makers use them for sleek, custom designs. Even marine applications use them for boat parts.

Curved aluminum extrusions are important in building design. Architects use them to create unique shapes. These shapes make buildings look modern and stylish. For example, they can form the frames for large, curved glass walls. This allows more natural light inside. They also make curved roofs or decorative elements. This adds a special touch to a building’s look. The material is light, so it does not add much weight to the structure. This helps in building tall structures. Aluminum also resists rust, which means it lasts a long time outside. This saves money on repairs.

In cars, trains, and planes, curved aluminum extrusions are very useful. Car makers use them for strong but light parts. This includes parts of the car body or internal structures. Using light materials helps vehicles use less fuel. This is good for the environment and saves money. For trains, these extrusions can form parts of the train’s frame or interior. In planes, they make parts of the wing or fuselage. The ability to bend aluminum into complex curves helps engineers design safer and more efficient vehicles. These parts must be very precise. Our factory ensures that every part meets exact design needs.

Curved aluminum extrusions are also popular in making furniture. Designers use them to create modern, stylish pieces. This includes chairs, tables, and decorative items. The curves add a smooth, elegant look. They can also be used in lighting fixtures. This allows for unique light designs. In other products, like display cases or custom enclosures, these extrusions provide both strength and good looks. They are easy to shape, so they can fit many different product ideas. This flexibility makes them a top choice for custom product needs.

Here is a table showing common uses:

| Application Area | Specific Examples | Key Benefits |

| Architecture | Building facades, skylights, curved roofs | Aesthetic appeal, lightweight, corrosion resistance |

| Transportation | Vehicle frames, interior trims, train components | Lightweight, fuel efficiency, structural integrity |

| Furniture | Chairs, tables, decorative elements | Modern design, durability, versatility |

| Marine | Boat parts, yacht structures | Corrosion resistance, strength-to-weight ratio |

I’ve often heard people question if the extra effort for curved parts is truly worth it. From my experience, the advantages are quite clear once you see them.

Curved aluminum extrusions offer many benefits. They are very strong but also light, which saves on shipping costs. They resist rust well, making them last longer in bad weather. Their ability to be shaped into complex curves allows for creative designs. This also helps reduce how many parts are needed in a project. They are also easy to recycle, making them an eco-friendly choice.

One big advantage of curved aluminum extrusions is their great strength-to-weight ratio. Aluminum is naturally light. When it is extruded and then curved, it keeps its strength. This makes it perfect for structures where weight is important, like in vehicles or large buildings. A lighter structure means less stress on foundations and lower fuel use for transport. This helps companies save money. It also makes products easier to handle and install. The specific shape of the curve also adds to the strength. This lets designers use less material while still meeting safety needs.

Aluminum naturally forms a thin layer of oxide on its surface. This layer protects the metal from rust and other damage. This means curved aluminum extrusions last a long time, even in wet or salty places. This makes them good for outdoor uses, like building facades or marine parts. Unlike steel, aluminum does not rust red. This keeps products looking good for many years. This also means less need for painting or special coatings. This lowers maintenance costs over time. For businesses, this means products that stay strong and look new for longer periods.

The ability to bend aluminum into many shapes is a huge benefit. Designers are not limited to straight lines. They can create unique, eye-catching designs. This helps products stand out. It also lets engineers make parts that fit into tight spaces. This is important in complex machines or vehicle designs. The curving process can make one piece do the job of several straight pieces. This simplifies assembly and reduces part count. This can also cut down on production time and costs. Our factory can make custom shapes to fit any design idea.

Aluminum is a very eco-friendly material. It can be recycled many times without losing its quality. This means that used curved aluminum extrusions can be melted down and made into new products. This uses much less energy than making new aluminum from raw materials. Using recycled aluminum helps lower carbon emissions. It also reduces the need to mine new materials. For companies focused on being green, choosing aluminum is a smart move. Our production process aims to be as efficient as possible. This helps reduce waste.

Here is a comparison of aluminum with other materials:

| 기능 | Aluminum Extrusions | Steel | Plastic |

| 무게 대비 강도 비율 | 높음 | Medium | 낮음 |

| 내식성 | 우수 | Poor (without coating) | Good |

| 디자인 유연성 | 높음 | Medium | 높음 |

| 재활용 가능성 | 우수 | Good | Variable |

| Weight | Light | Heavy | Very Light |

I often get questions about how much curved aluminum extrusions cost. People want to know what affects the price.

The cost of curved aluminum extrusions changes based on several things. The type of aluminum alloy used, how complex the curve is, and the total order quantity all play a role. Specialized finishes like powder coating or anodizing also add to the price. The tooling costs for new dies can be a factor. Shipping expenses also impact the final cost, especially for large orders.

Many things make up the final cost of curved aluminum extrusions. First is the material itself. Different aluminum alloys have different prices. Stronger or more specialized alloys usually cost more. Second, the complexity of the curve matters a lot. Simple curves are cheaper to make than very tight or unusual shapes. Third, the order size is important. Buying a larger amount often means a lower price per piece. This is because setup costs are spread over more items. Our factory works with large, wholesale orders. This makes us a good choice for big companies.

When a new design for curved aluminum extrusions is needed, a special tool called a die must be made. The cost of this die is a one-time charge. It can be a big part of the first order. But for repeat orders, this cost is not there. After the extrusion is made, it often needs a finish. Common finishes include powder coating, anodizing, or polishing. Powder coating adds color and protection. Anodizing makes the surface harder and more resistant to scratches. Each finish adds to the total cost. The choice of finish depends on how the part will be used and how it needs to look.

For large orders, especially those from overseas, shipping costs are a big part of the price. The size and weight of the extrusions affect how much shipping costs. Also, the distance they travel is important. Our company provides full supply chain services. This includes managing logistics. We make sure products get to our customers in the United States, Canada, and Europe efficiently. We also handle quality control during shipping. This ensures that products arrive in perfect condition. We aim to make the process easy and clear for our customers.

Here is a table of cost factors:

| Cost Factor | 설명 | Impact on Price |

| Material Type | Specific aluminum alloy used | Higher for specialized alloys |

| Curve Complexity | Tightness and shape of the bend | Higher for complex shapes |

| Order Quantity | Number of units purchased | Lower price per unit for larger orders |

| 툴링 | Cost of custom dies for new designs | One-time cost, amortized over units |

| Finishing | Surface treatments like powder coating | Adds to per-unit cost |

| Shipping | Transport from factory to customer | Varies by distance, weight, and volume |

I often get inquiries from purchasing managers seeking reliable sources for specialized parts. Knowing where to look for quality and service is crucial.

You can find curved aluminum extrusions from specialized manufacturers like us, ALUT. We are a B2B wholesaler with factories in China. We custom make aluminum products based on customer drawings or samples. We also offer standard products. Our services include supplier procurement, quality control, and logistics management for buyers in North America and Europe.

When looking for curved aluminum extrusions, it is best to go to a specialized manufacturer. Our brand, ALUT, is based in China. We have a factory larger than 10,000 square meters. We focus on customized aluminum products. We work with large companies, purchasing managers, and product managers. We are a B2B wholesale supplier. We do not sell small amounts. This means we are set up to handle big orders. We can make products exactly as our customers need them. This includes making parts from specific drawings or samples. Our main export markets are the United States, Canada, and Europe. We understand the needs of buyers in these regions.

We offer more than just making parts. We provide a full range of supply chain services. This starts with supplier procurement. We help find the right materials and processes. We also do supplier audits to make sure quality standards are met. During production, we manage contract manufacturing and process control. This means we watch every step of how the parts are made. Most important is quality inspection. We check every product to ensure it meets design needs. We know that exact dimensions are very important for our customers. We also handle logistics management. This makes sure products arrive on time and safely. Our goal is to make the entire process smooth for our customers.

Choosing ALUT means working with a partner who understands your needs. We know that professionalism is key. Our sales team gives clear, expert replies. We avoid delays, which prevents your downstream customers from stopping production. We focus on strict quality control. This ensures that all product dimensions and specifications are correct. Our customers value our ability in engineering design, project management, and quality control. We offer flexible payment terms. This includes credit options for trusted partners. We also help customers avoid high tariffs by offering manufacturing in Vietnam when possible. This makes us a reliable choice for your aluminum extrusion needs.

Here is a summary of our services:

| Service Category | 설명 | Benefit to Customers |

| 제조 | Custom and standard aluminum products | Exact parts for specific needs |

| Supply Chain | Order management, QC, logistics | Smooth process, on-time delivery |

| 품질 관리 | Inspections, audits, process control | High-quality products, reduced defects |

| Design Support | Engineering design capabilities | Optimized product performance |

| Tariff Solutions | Manufacturing in Vietnam options | Cost savings on imports |

Finding the right partner for curved aluminum extrusions is crucial for project success. ALUT offers reliable, high-quality, and customized solutions. We focus on meeting your needs with expert service and efficient supply chain management.