住所

304ノース・カーディナル

セント・ドーチェスター・センター(マサチューセッツ州02124

勤務時間

月曜日~金曜日:午前7時~午後7時

週末午前10時~午後5時

Have you ever struggled to find the perfect component for your project? I know I have. Tiny details can make or break a design, right?

I’ve seen firsthand how small aluminum extrusions offer incredible precision and versatility, making them indispensable for countless applications. Their unique properties solve many engineering challenges.

Let’s dive deeper and uncover the amazing world of small aluminum extrusions and why they are so crucial.

Do you ever wonder where these small, precise parts end up? It’s fascinating how many products rely on them.

From consumer electronics to automotive parts, I’ve observed that small aluminum extrusions are everywhere. They are critical for heat sinks, structural components, and decorative trims.

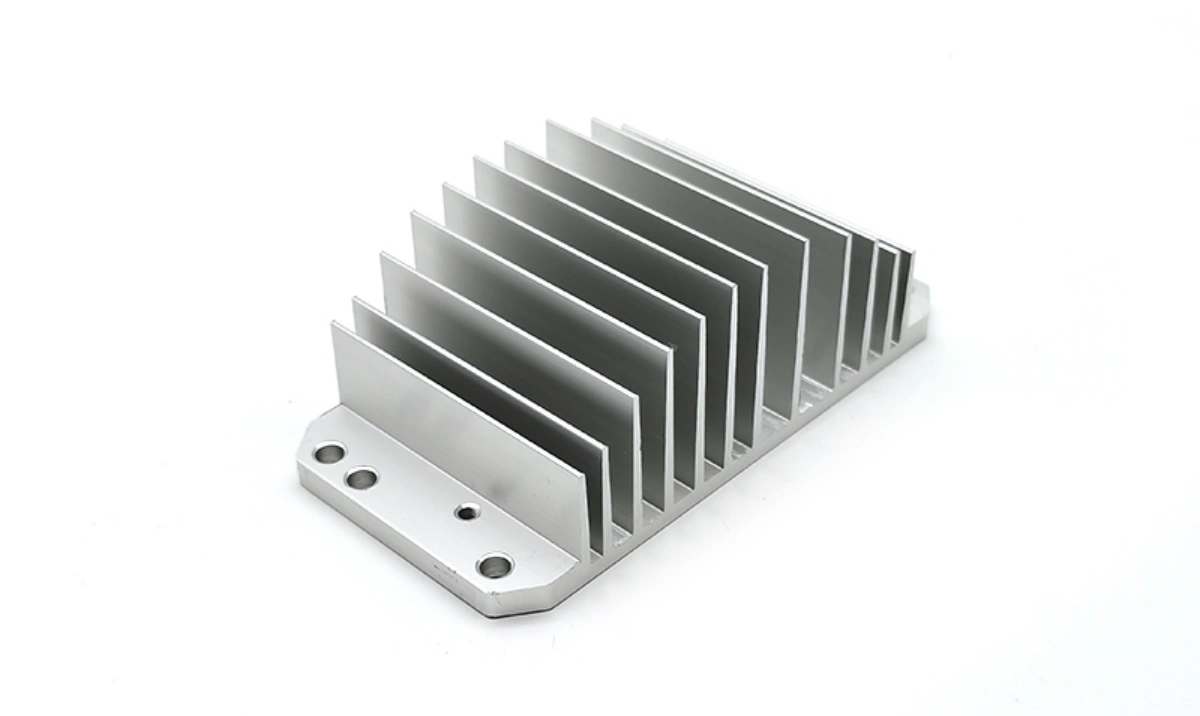

Small aluminum extrusions are perfect for making parts for electronics. For example, they are used to create heat sinks. Heat sinks pull heat away from sensitive electronic parts. This stops the parts from getting too hot and breaking. Think about your computer or an LED light. They both need to stay cool. Aluminum is great at conducting heat. So, it is a top choice for these parts. Also, these extrusions can make strong, light cases for electronic devices. This keeps the inside parts safe.

In cars, small aluminum extrusions help make many parts lighter and stronger. For instance, they are used for interior trim pieces. They also form small structural supports. Car makers want to cut down on weight. This helps cars use less fuel. Aluminum is light, but it is also strong. So, it is a good material for car parts. These small extrusions can be shaped into complex forms. This makes them useful for custom car designs.

Medical equipment needs to be very precise and reliable. Small aluminum extrusions fit this need well. They are used for parts in diagnostic tools and surgical instruments. The material is easy to clean and sterilize. It does not react with many chemicals. This makes it safe for medical use. Their light weight is also good for portable medical devices.

Look around your home. Small aluminum extrusions are probably there. They are used in furniture, appliances, and even sports equipment. For example, they can form tracks for sliding doors. They can also make strong frames for small items. Their ability to take on different shapes helps designers create new products. People like the look of aluminum. It often makes products look modern and clean.

Different industries choose small aluminum extrusions for clear reasons. These reasons include:

| 産業 | 一般的な用途 | Key Benefits |

| エレクトロニクス | Heat sinks, enclosures | Thermal conductivity, lightweight, EMI shielding |

| 自動車 | Trim, structural supports | Lightweight, strength, corrosion resistance |

| メディカル | Instrument housings, guides | Sterilizable, precision, corrosion resistance |

| Consumer | Furniture components, frames | Aesthetics, strength, versatile shapes |

Have you ever thought about what goes into designing these tiny but mighty parts? It’s more complex than you might imagine.

When I design small aluminum extrusions, I always focus on material choice, wall thickness, and tolerance. These factors are crucial for performance and cost-effectiveness.

Choosing the right aluminum alloy is the first step. Different alloys have different strengths and uses. For small aluminum extrusions, alloys like 6061 and 6063 are common.

The alloy you pick depends on what the small aluminum extrusions will be used for. For example, a part needing high strength will use a different alloy than a decorative trim piece.

The thickness of the walls of the extrusion is very important. It affects the strength and weight of the part. Thinner walls save material and reduce weight. But they can also make the part less strong. Thicker walls make the part stronger but add weight and cost.

Designers must find a balance. They need to meet the strength needs while keeping the weight and cost low.

Tolerances are the allowed variations in the size of the small aluminum extrusions. All manufactured parts have small differences from the design. Tolerances define how much difference is acceptable.

Designers must specify tolerances that meet the part’s function. They also need to be realistic for manufacturing. My team at ALUT always ensures strict quality control to meet these exact tolerances.

The shape of the small aluminum extrusions also matters. Complex shapes can offer many benefits. They can add strength without extra material. They can also create channels for wires or mounting points. However, very complex shapes can be harder to extrude. This might increase the cost and time to make them.

| Design Factor | 主な検討事項 | Impact on Product |

| 素材 | Alloy type (e.g., 6061, 6063) | Strength, corrosion resistance, finish |

| 壁厚 | Minimum and maximum thickness | Weight, structural integrity, cost |

| 公差 | Permitted size variations | Fit, function, manufacturing cost |

Have you ever wondered why aluminum extrusions are so popular, especially the small ones? I’ve seen their benefits firsthand in countless projects.

I’ve learned that small aluminum extrusions offer unmatched strength-to-weight ratio, excellent corrosion resistance, and incredible design flexibility. These features make them a superior choice.

One of the biggest benefits of small aluminum extrusions is their high strength-to-weight ratio. Aluminum is a light metal. But it can be very strong when shaped correctly. This means you get strong parts without adding much weight. This is very important in industries like aerospace and automotive. In these fields, every gram of weight matters. Lighter parts lead to better fuel efficiency and performance. For example, a small aluminum frame can be as strong as a steel one, but much lighter. This makes it easier to handle and assemble. It also reduces shipping costs.

Aluminum naturally forms a thin oxide layer on its surface. This layer protects the metal from rust and other forms of corrosion. This means small aluminum extrusions can be used in harsh environments. They work well outdoors or in places with high humidity. This natural protection saves money because you don’t need extra coatings for many uses. For example, parts used in marine settings or outdoor lighting will last a long time. This is because small aluminum extrusions resist corrosion so well.

The extrusion process allows for very complex and detailed shapes. This is a huge advantage for small aluminum extrusions. Designers can create custom profiles with internal channels, intricate fins, and precise mounting features. This flexibility means one extrusion can do the job of several parts. This reduces assembly time and costs. It also opens up new possibilities for product design. For example, a single extrusion can serve as a heat sink, a structural support, and a housing for wires all at once. This ability to integrate multiple functions into one part is truly powerful.

Small aluminum extrusions also have other benefits:

| メリット | 説明 | 適用例 |

| Strength-to-Weight | Strong yet lightweight | Automotive components, portable devices |

| 耐食性 | Resists rust and degradation | Outdoor fixtures, marine applications |

| デザインの柔軟性 | Complex shapes possible | Multi-functional profiles, custom enclosures |

Have you ever wondered which industries rely most on these versatile components? The reach of small aluminum extrusions is quite impressive.

From what I’ve seen, small aluminum extrusions are indispensable in electronics, automotive, and construction. They are valued for their precision and adaptability in these sectors.

The electronics industry uses a lot of small aluminum extrusions. They are key for parts that need to manage heat. For instance, tiny heat sinks keep computer chips cool. Without them, devices would overheat and fail. Extrusions also make strong, light cases for phones, tablets, and other gadgets. These cases protect delicate internal components. The material’s ability to block electromagnetic interference (EMI) is another big plus. This ensures electronic devices work correctly without signal problems. Companies often need custom shapes for their unique products. Small aluminum extrusions can be made into almost any shape needed.

In the automotive sector, small aluminum extrusions help make cars lighter and more efficient. They are used for interior trim, dashboard parts, and small structural elements. Reducing vehicle weight is a major goal for car manufacturers. Lighter cars use less fuel and produce fewer emissions. Aluminum’s strength means these parts can be thin but still very strong. This helps cars meet safety standards. Also, the corrosion resistance of aluminum means parts will last longer, even in harsh weather conditions. This is important for both the car’s performance and its appearance over time.

Small aluminum extrusions also play a role in construction. They are used for window frames, door frames, and decorative elements. Their light weight makes them easy to install. Their strength ensures they are durable. Aluminum does not rust, which is perfect for outdoor use. They can be finished in many colors and textures. This gives architects and builders many design choices. Small extrusions can create sleek, modern looks for buildings. They are also used for railing systems and sun shades.

Many other industries depend on small aluminum extrusions:

| 産業 | Primary Use of Small Aluminum Extrusions | Reason for Use |

| エレクトロニクス | Heat sinks, enclosures | Thermal management, EMI shielding, lightweight |

| 自動車 | Trim, structural components | Weight reduction, strength, corrosion resistance |

| Construction | Window/door frames, decorative | Durability, aesthetics, corrosion resistance |

Small aluminum extrusions are vital for many products. They offer strength, light weight, and flexibility. Their benefits make them essential in today’s manufacturing world.