住所

304ノース・カーディナル

セント・ドーチェスター・センター(マサチューセッツ州02124

勤務時間

月曜日~金曜日:午前7時~午後7時

週末午前10時~午後5時

Struggling with your project’s material choice? The wrong aluminum extrusion can cause costly delays. I’m here to help you understand the essential aluminum extrusion types for success.

From my experience, understanding the fundamental differences between solid, hollow, and semi-hollow aluminum extrusion types is critical. The choice ultimately depends on your project’s specific structural needs, weight requirements, and final application, ensuring you get a flawless result every time.

But knowing the basic categories is just the start. Let’s break down the details that truly matter for your next big order of aluminum extrusion types.

Confused about solid versus hollow profiles? This choice impacts your product’s strength and cost. I’ll clarify the key differences so you can make a confident decision for your aluminum extrusion types.

I always tell my clients that solid aluminum extrusion types have no enclosed voids and are best for strength. In contrast, hollow types have one or more voids, making them lighter and ideal for fluid or wire management. Your choice here directly affects weight and function.

The decision between a solid or hollow profile is one of the first and most important you’ll make. It’s not just about looks; it’s about engineering, cost, and the final performance of your parts. In my years of running a factory, I’ve seen how this single choice can make or break a product’s design. These two fundamental aluminum extrusion types serve very different purposes.

Solid profiles are exactly what they sound like: a single, solid piece of aluminum with no enclosed openings. Think of solid bars, rods, angles, and beams. Their primary advantage is their raw strength and simplicity in manufacturing.

Because there are no empty spaces, they have a high degree of structural integrity and can bear significant loads without buckling. We often produce these solid aluminum extrusion types for applications where strength is non-negotiable, such as:

The trade-off, of course, is weight and material cost. More material means a higher unit price and a heavier final product, which can increase shipping costs.

I recall a purchasing manager who insisted on a solid profile for a machine guard rail, fearing a hollow one would fail. We ran a quick analysis and showed him that a well-designed hollow profile could meet his safety requirements while reducing the part’s weight by 30%. This simple change saved his company a significant amount on both material and logistics.

Hollow profiles, which contain one or more enclosed voids, are engineering marvels. Common examples are square, rectangular, and round tubes. Their primary benefit is an excellent strength-to-weight ratio.

They provide substantial rigidity while using less material, making them lighter and often more cost-effective. These hollow aluminum extrusion types are perfect for window frames, enclosures for electronics, and tubing for fluid transfer.

The manufacturing process for hollow shapes is more complex, requiring a special die with an internal mandrel to form the void. This can slightly increase initial tooling costs.

However, for any significant production run, the material savings almost always outweigh this one-time investment. Understanding these nuances is key to optimizing your design for both performance and cost.

| 特徴 | Solid Extrusion | Hollow Extrusion |

| Structure | No enclosed voids | One or more enclosed voids |

| 強さ | Very high | High strength-to-weight ratio |

| Weight | Heavier | Lighter |

| Cost | Higher material cost | Lower material cost |

| Best For | Heavy loads, structural parts | Frames, enclosures, fluid transfer |

Ever wonder about all those different shapes? Picking the wrong profile shape complicates assembly. I’ll show you the most common aluminum extrusion types and their best uses.

In our factory, the most common aluminum extrusion types we produce are standard shapes like L-channels, U-channels, T-slots, and round tubes. I find that these profiles form the backbone of countless industrial and consumer products, from framing systems to electronic enclosures.

Standard shapes are great, but the real power is in understanding their specific jobs. When a client sends me a drawing, the profile shape tells me a story about how the part will be used and what stresses it will face.

Getting this right prevents major headaches during assembly. It’s the difference between a smooth production process and a frustrating, costly one.

T-slot aluminum extrusion types are incredibly popular for building modular frames. Think of machine guards, ergonomic workstations, custom shelving, or even frames for 3D printers and automation lines.

The “T” shaped slot is their defining feature. It allows you to connect other parts and accessories using special T-nuts and fasteners. This means you can build, modify, and disassemble structures with simple hand tools—no welding or specialized labor required.

It’s like a life-sized, high-strength construction set for engineers. The versatility of these aluminum extrusion types makes them a favorite for projects that require flexibility and future modification.

U-channels and C-channels are workhorses for framing and support. You’ll see them used as edge protectors on panels or tracks for sliding doors.

But the real value a B2B partner provides is creating custom aluminum extrusion types. A custom profile is a unique shape designed for a specific function, which can reduce part counts and lower costs.

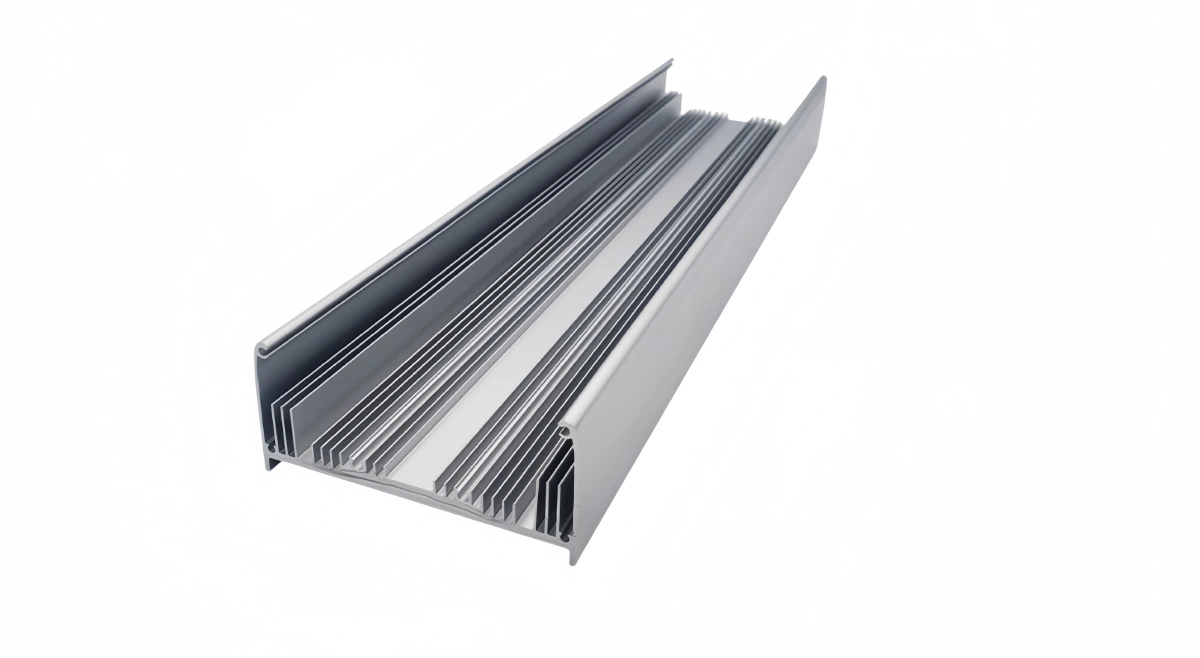

A client in the LED lighting industry came to us with a design that used three separate parts. We worked with their engineers to combine them into a single, complex custom extrusion. This single part made their product stronger, easier to assemble, and ultimately, less expensive to produce. This collaborative engineering is the core of what we do.

| プロフィール・タイプ | Key Feature | Primary Use | 金型費用 |

| T-Slot | Modular connection slot | Machine frames, workstations | Low (Standard) |

| U-Channel | Three-sided channel | Edging, tracks, simple frames | Low (Standard) |

| Custom | Unique, multi-functional shape | Part consolidation, specific designs | High (Custom Die) |

Does the alloy number seem like a secret code? Choosing the wrong one leads to product failure. I’ll decode the most common alloys used for aluminum extrusion types.

I constantly advise buyers that the alloy choice is just as important as the shape. The most popular aluminum extrusion types use 6061 for its superior strength and 6063 for its excellent surface finish and corrosion resistance. The choice defines the final performance.

An alloy is simply aluminum mixed with other elements like magnesium or silicon. These additions give the aluminum specific, predictable properties.

A supplier who just says “we use 6000 series” isn’t giving you the full picture. You need to know which one and why. This knowledge is crucial for quality control and ensuring your part performs exactly as designed.

When you need strength, 6061 is your go-to alloy, especially in its T6 temper state. The “T6” indicates it has been solution heat-treated and then artificially aged, a process that significantly increases its strength.

It’s often used for structural applications where the part will be under stress. This includes machine parts, bicycle frames, and automotive components. It also welds and machines very well, making it a versatile choice for complex parts.

The downside is that its surface finish is not as smooth as 6063. So, if your product’s cosmetic appearance is the absolute top priority, you might look at other options. But for function and strength, 6061 is one of the most reliable aluminum extrusion types available.

6063 is the most common alloy for aluminum extrusion types where appearance and surface quality are key. It has a fantastic, smooth surface finish that is perfect for anodizing.

It also has great corrosion resistance, making it ideal for products exposed to weather. This is why you see it used everywhere in architectural applications like window frames, door frames, and decorative trim.

It’s not as strong as 6061, but its strength is more than sufficient for most non-structural applications. Its composition also allows it to be pushed through more complex dies. When a customer wants a beautiful, smooth finish, I almost always recommend 6063.

Is your finished product not looking or lasting as expected? The surface finish is often overlooked. I’ll explain the options that protect and beautify your aluminum extrusion types.

I believe the finish is the final, critical step. The most common finishes applied to aluminum extrusion types are anodizing for durability and color, and powder coating for a tough, decorative layer. These protect the metal and enhance its appearance for the end-user.

Raw aluminum, straight from the extrusion press, has a “mill finish.” It’s functional, but it will oxidize and become dull over time. A proper finish protects the aluminum from corrosion and provides a desired look.

You need to specify the finish just as clearly as you specify the alloy and dimensions. This avoids any surprises when you receive your shipment.

Anodizing is an electrochemical process that creates a very hard, durable, and corrosion-resistant layer on the aluminum surface. It’s not a coating like paint; the process grows the protective oxide layer right from the aluminum itself. This is why it can’t chip, flake, or peel.

There are different types. Type II Anodizing is used for decorative purposes and is where we can add rich, metallic colors. Type III Anodizing, or hardcoat, creates a much thicker layer that is extremely resistant to abrasion—often used for industrial machine parts.

Controlling the anodizing process is critical. We manage it carefully to ensure consistent color and thickness. A thick coating can change dimensional tolerances, so precision is key.

Powder coating is like a very durable, baked-on paint job. A dry powder is sprayed onto the part and then baked in an oven, where it cures into a hard shell.

The main advantage is the nearly unlimited range of colors and textures available. It’s tougher than liquid paint and more environmentally friendly. It’s a great choice for many aluminum extrusion types used in consumer products or outdoor furniture.

Before coating, mechanical finishes like brushing or bead blasting can be applied. These create a uniform surface texture and can hide minor imperfections from the extrusion process.

Understanding the core aluminum extrusion types, profiles, alloys, and finishes is key. This knowledge empowers you to make the right choices for a successful, high-quality project.