住所

304ノース・カーディナル

セント・ドーチェスター・センター(マサチューセッツ州02124

勤務時間

月曜日~金曜日:午前7時~午後7時

週末午前10時~午後5時

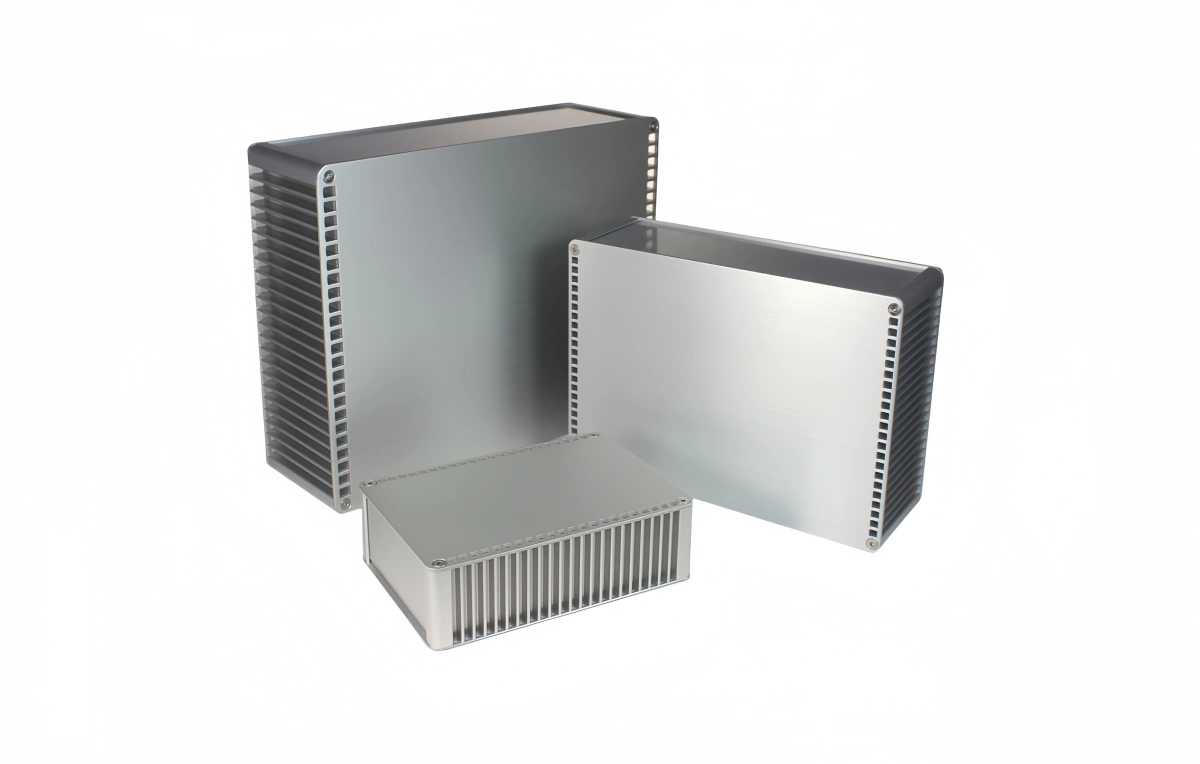

Are your crucial components at risk from dust or corrosion? I’ve seen cheap enclosures fail, causing massive project delays. Let’s explore why a NEMA 4X aluminum enclosure is a reliable solution.

From my experience, a NEMA 4X aluminum enclosure is more than just a box. It’s an essential protective shield. It guarantees your equipment is safe from dust, water, and especially corrosion, making it perfect for both indoor and outdoor applications where chemicals or salt spray are a concern.

But what really makes it “4X”? And is it always the best choice compared to other materials like stainless steel? Let’s dive into the details to give you the clarity you need for your next project.

Confused by all the NEMA ratings? I get it. Picking the wrong one can be a costly mistake. Let’s clear up exactly what “4X” means for your project’s safety.

I tell my clients that a NEMA 4X aluminum enclosure is a specific type of electrical housing. It’s certified to be dust-tight, waterproof against splashing and hose-downs, and crucially, extra corrosion-resistant. This ‘X’ is your guarantee against rust and chemical damage.

To truly understand the value of a NEMA 4X aluminum enclosure, we first need to know who sets the standards. NEMA stands for the National Electrical Manufacturers Association. This organization defines standards for electrical enclosures in North America. These ratings are not just suggestions; they are a benchmark for performance and safety that purchasing managers like you rely on.

The rating itself tells a story. Let’s break it down piece by piece:

For professionals in industries like food and beverage, marine, or wastewater treatment, this rating is non-negotiable. It ensures that sensitive controls, electronics, and wiring are shielded from the elements that would quickly degrade lesser enclosures. A standard NEMA 4 enclosure might keep water out, but it won’t stand up to the corrosive effects of a chemical washdown or salty air over time.

Is the ‘X’ really worth the potential extra cost? I’ve seen projects suffer from this one small oversight. Let’s make sure you don’t make the same mistake.

In my professional opinion, you choose a NEMA 4X over a NEMA 4 aluminum enclosure for one critical reason: corrosion. If your equipment will be near salt water, chemicals, or in a regular washdown area, that ‘X’ is non-negotiable for long-term reliability.

The decision between NEMA 4 and NEMA 4X often comes down to understanding the total cost of ownership, not just the initial purchase price. As a manufacturer, I’ve seen this firsthand. A client once tried to save a small amount on their budget by opting for standard NEMA 4 enclosures for an installation near a marina. They protected against rain just fine, but within 18 months, the salt in the air had corroded the latches and hinges. The seals were compromised, leading to moisture ingress and costly equipment failure. Replacing the failed units and the damaged electronics inside cost them ten times their initial savings.

That ‘X’ is a promise of durability in specific, harsh conditions. Both ratings protect against hose-directed water, but only the 4X is specifically tested for corrosion resistance. This is usually done through a 200-hour salt spray test, which simulates years of exposure in a corrosive environment. A NEMA 4X aluminum enclosure is designed to pass this test. A standard NEMA 4 enclosure is not.

Here is a simple table to clarify the difference:

| 特徴 | NEMA 4 Enclosure | NEMA 4X Enclosure |

| Water Protection | Excellent (Hose-downs) | Excellent (Hose-downs) |

| Dust Protection | Excellent (Windblown dust) | Excellent (Windblown dust) |

| Corrosion Protection | Basic | Superior (Passes salt-spray test) |

| Ideal Environment | General-purpose outdoor/indoor | Corrosive environments (Coastal, chemical plants) |

As a purchasing manager, your goal is to prevent production stops and ensure product reliability. Specifying a NEMA 4X aluminum enclosure is a proactive step in risk management. You should insist on the ‘X’ when the enclosure will be installed in:

Choosing the NEMA 4X isn’t about over-engineering; it’s about matching the product’s specification to its real-world environment.

Aluminum or stainless steel? This is a common question I get. The choice impacts your budget, weight, and installation. Let’s break down the pros and cons for you.

Based on my manufacturing experience, I advise that a NEMA 4X aluminum enclosure is lighter and more cost-effective. Stainless steel offers superior durability against physical impact and extreme chemical exposure, but for most corrosive environments, aluminum is the ideal balance of performance and price.

Both aluminum and stainless steel can be used to build a high-quality NEMA 4X enclosure. The best choice for your project depends on a few key factors. As a supplier, my job is to help you select the material that provides the best value and performance for your specific application, avoiding the pain points of over-specifying or under-specifying. Let’s look at a direct comparison.

The right material choice depends on a trade-off between cost, weight, and resistance to specific hazards. Both are excellent choices for corrosion resistance, but they have distinct advantages in other areas.

| Factor | NEMA 4X Aluminum Enclosure | NEMA 4X Stainless Steel Enclosure |

| Cost | More economical | More expensive |

| Weight | 軽量 | Heavy (Approx. 3x heavier) |

| Heat Dissipation | 素晴らしい | Poor |

| 耐衝撃性 | グッド | Superior |

| Ideal Use Case | Most industrial/marine uses | Heavy-duty, high-impact areas |

For the majority of B2B applications my clients have, a NEMA 4X aluminum enclosure provides the necessary corrosion protection and durability without the added expense and weight of stainless steel. It is the practical, high-value choice for protecting electronics in most demanding environments.

You’ve made the right choice, but an enclosure is only as good as its seal. I’ve seen poor maintenance compromise even the best products. Let’s ensure your investment lasts.

From my quality control perspective, maintaining a NEMA 4X aluminum enclosure’s rating is about the gasket. I always recommend regular inspection for cracks or compression and ensuring latches provide even pressure. A clean, intact gasket is your first line of defense.

An enclosure’s rating is not a one-time certification; it’s a performance level that must be maintained throughout its service life. Neglecting simple maintenance can lead to seal failure, which is a primary pain point that causes product damage and costly downtime. As a manufacturer focused on quality control, we build our enclosures to last, but proper care in the field is essential. A regular inspection routine for your NEMA 4X aluminum enclosure is simple, quick, and can prevent catastrophic failures.

I recommend a simple checklist that your maintenance teams can follow. This proactive approach ensures the enclosure continues to provide the NEMA 4X protection you paid for.

| Inspection Area | What to Look For | Action Required |

| Gasket | Cracks, brittleness, tears, or being overly compressed. | Replace the gasket immediately if any damage is found. |

| Latches/Clamps | Looseness, corrosion, or damage. | Tighten, clean, or replace latches to ensure a firm, even seal. |

| Enclosure Body | Dents, deep scratches, or unauthorized drill holes. | Repair deep scratches. Ensure any new holes are sealed with a NEMA 4X-rated fitting. |

| Hinges | Corrosion or stiffness. | Clean and lubricate hinges to ensure the door closes properly and evenly. |

The gasket is the most critical component for maintaining the seal. It’s typically made of silicone, neoprene, or EPDM. Over time, these materials can degrade from exposure to UV light or chemicals. During an inspection, gently feel the gasket. It should be pliable, not hard or cracked. When the door is closed, the latches should compress the gasket evenly all the way around. If you see gaps or the gasket looks flat and lifeless, it’s no longer creating a proper seal.

One of the most common ways a NEMA 4X aluminum enclosure loses its rating is through improper modifications. If you need to drill holes for cables or conduits, you must use a NEMA 4X-rated cable gland or hub. Simply drilling a hole and passing a cable through it completely voids the rating. Ensure that any fittings are correctly installed and tightened to maintain the watertight and dust-tight seal. This is a detail that prevents major quality control issues down the line.

A NEMA 4X aluminum enclosure is a smart investment in reliability. Understanding its features and proper maintenance ensures your critical components remain protected, securing your project’s long-term success.