住所

304ノース・カーディナル

セント・ドーチェスター・センター(マサチューセッツ州02124

勤務時間

月曜日~金曜日:午前7時~午後7時

週末午前10時~午後5時

Need a sleek black finish but worried it will scratch or fade? A poor finish ruins a premium product. I’ll explain how to get a durable, perfect black aluminum extrusion.

In my experience, the ultimate secret to a flawless black aluminum extrusion is choosing the right process. I always recommend black anodizing over paint for its superior durability and deep, consistent color. This engineered finish is key to a premium, long-lasting product.

But the process is just one part of the story. The real-world performance depends on details that many suppliers overlook. Let’s dive in.

Confused about paint versus anodizing for your parts? Choosing wrong can lead to chipping and a cheap look. I’ll explain the two main methods for black aluminum extrusion.

I tell my clients that a true black aluminum extrusion can be either, but for professional results, we almost always use black anodizing. Anodizing integrates the color into the metal itself. Paint, on the other hand, is just a surface layer that can chip.

This is a critical distinction that impacts everything from durability to the final look and feel of your product. As a factory owner, I see firsthand how these two methods produce vastly different results. The choice you make here defines the quality of your final component.

Anodizing is not paint. It is an electrochemical process that converts the metal surface into a durable, corrosion-resistant, anodic oxide finish. We submerge the aluminum extrusion in an acid electrolyte bath and pass an electric current through it. This grows a very hard, porous layer of aluminum oxide directly from the underlying aluminum.

For a black aluminum extrusion, we then immerse the part in a black dye bath. The dye particles seep deep into those open pores. The final step is sealing. We treat the part with hot water or chemical sealants, which closes the pores and permanently traps the color particles beneath the ultra-hard outer layer. This means the color can’t be flaked or chipped off, because it’s part of the metal itself.

Painting, including powder coating, is a surface application. The process involves thoroughly cleaning the part, then spraying it with either liquid paint or a dry powder. The part is then cured, usually with heat, which causes the coating to adhere to the surface.

While modern paints and powder coats are quite durable, they are still a separate layer on top of the aluminum. A sharp impact or deep scratch can break through this layer and expose the bare metal underneath, leading to chipping and potential corrosion.

A client once came to us after their previous supplier used black spray paint on parts for an outdoor electronics enclosure. The paint started peeling in six months. We remade the order with a proper black anodized finish, and the problem was solved. This is why understanding the process for a black aluminum extrusion is so important.

| 特徴 | Black Anodizing | Black Painting / Powder Coating |

| 方法 | Electrochemical, integral to the part | Surface application, a separate layer |

| Durability | Extremely hard, cannot chip or peel | Tough, but can be chipped or scratched off |

| Appearance | Deep, rich metallic sheen | Can be matte, gloss, or textured |

| Best For | High-wear, premium, and outdoor uses | Specific colors or textures, lower-wear uses |

Worried your black finish will scratch or fade over time? A failed finish can ruin your product’s reputation. I’ll explain what makes a black aluminum extrusion truly durable.

From what I see in my factory, a properly anodized black aluminum extrusion is incredibly durable. Its surface hardness is second only to diamond, offering superior resistance to scratches, UV fading, and corrosion. It’s the most reliable finish we produce.

Durability isn’t just a marketing term; it’s a measurable engineering specification. For any product that will be handled, installed in a tough environment, or expected to look new for years, the durability of its finish is not optional. It is a core feature. Let’s break down what makes an anodized black aluminum extrusion so tough.

The key to its durability is the aluminum oxide layer created during anodizing. This layer is exceptionally hard. On the Mohs scale of mineral hardness, it rates a 9 out of 10, just behind diamond. This inherent hardness means it is extremely resistant to abrasion, scuffs, and scratches from daily use.

We supply parts for high-end audio equipment. The feel and look must be perfect. Our clients specify a hardcoat (Type III) black anodized finish because it resists scratches from rings and everyday handling, keeping the product looking new for years. This attention to detail is critical for a premium brand. The finish becomes a silent selling point, communicating quality long after the purchase.

Another major concern for any black finish is fading from sunlight. The beauty of an anodized black aluminum extrusion is that the dye is sealed deep within the protective oxide pores. This prevents UV rays from breaking down the color pigments, ensuring the part remains a deep, rich black even after years of outdoor exposure.

This same sealed, non-porous surface provides excellent corrosion protection. It acts as a barrier, preventing moisture and environmental salts from reaching the raw aluminum. This is why anodized parts are a standard in architectural and marine applications where weather resistance is essential. A painted finish, if scratched, can allow corrosion to creep underneath the paint layer, causing it to bubble and fail.

| Finish Type | Typical Thickness | Hardness (Mohs) | Best Use Case |

| Class II Anodize | 8-18 μm | ~9 | Architectural, consumer electronics |

| Type III Hardcoat | 25-50+ μm | 9 | Industrial, high-wear, military |

| Powder Coat | 60-120 μm | ~4 | Decorative, general industrial |

Thinking of using raw mill finish aluminum to save costs? This can backfire with corrosion and a cheap look. I’ll explain why a black aluminum extrusion is a better investment.

I always advise my customers to choose black aluminum extrusion over a raw mill finish. The black finish adds critical corrosion protection and a premium look. Mill finish is unprotected, oxidizes unevenly, and simply looks unfinished for a final product.

This is a conversation I have often with new purchasing managers. The upfront cost saving of skipping a finish is tempting, but it is almost always a mistake for a finished product. The difference in quality, longevity, and perceived value is enormous. Let’s look at the specific reasons why.

“Mill finish” is the raw state of the aluminum profile right after it comes out of the extrusion die. It often has faint lines from the process and has absolutely no protective layer. While aluminum doesn’t rust like steel, it does oxidize.

This natural oxidation creates a thin, soft, and uneven layer of aluminum oxide. This layer looks dull and chalky. It is easily stained by fingerprints, oils, and moisture, leading to a blotchy and unprofessional appearance. For any product that a customer will see or touch, mill finish communicates a lack of quality and attention to detail. It is suitable for parts that will be completely hidden from view or that will be finished later by the customer, but not for a final good.

A black aluminum extrusion, particularly one that is anodized, solves all these problems. The finish provides a controlled, uniform, and beautiful appearance. The deep black color is sleek, modern, and professional, which is essential for consumer electronics, architectural elements, and any product where look and feel are part of its value.

Beyond just looking good, the finish is functional. As we’ve discussed, it provides a hard, durable shell that protects the part from scratches and corrosion. You are adding a functional feature that extends the life of the product and keeps it looking new. It transforms a simple piece of metal into a high-performance, finished component. Choosing a black finish is an investment in your product’s quality and your brand’s reputation. It prevents customer complaints and warranty claims related to cosmetic failure down the line.

| Attribute | Mill Finish Aluminum | Black Anodized Aluminum |

| Aesthetics | Dull, uneven, industrial | Sleek, uniform, premium |

| 耐食性 | Poor | 素晴らしい |

| Durability | Poor (soft, easily stained) | Excellent (hard, scratch-resistant) |

| Perceived Value | 低い | 高い |

Need a specific shape but unsure if it’s available in black? Assuming limitations can stop your design cold. I’ll explain how you can get any profile as a black aluminum extrusion.

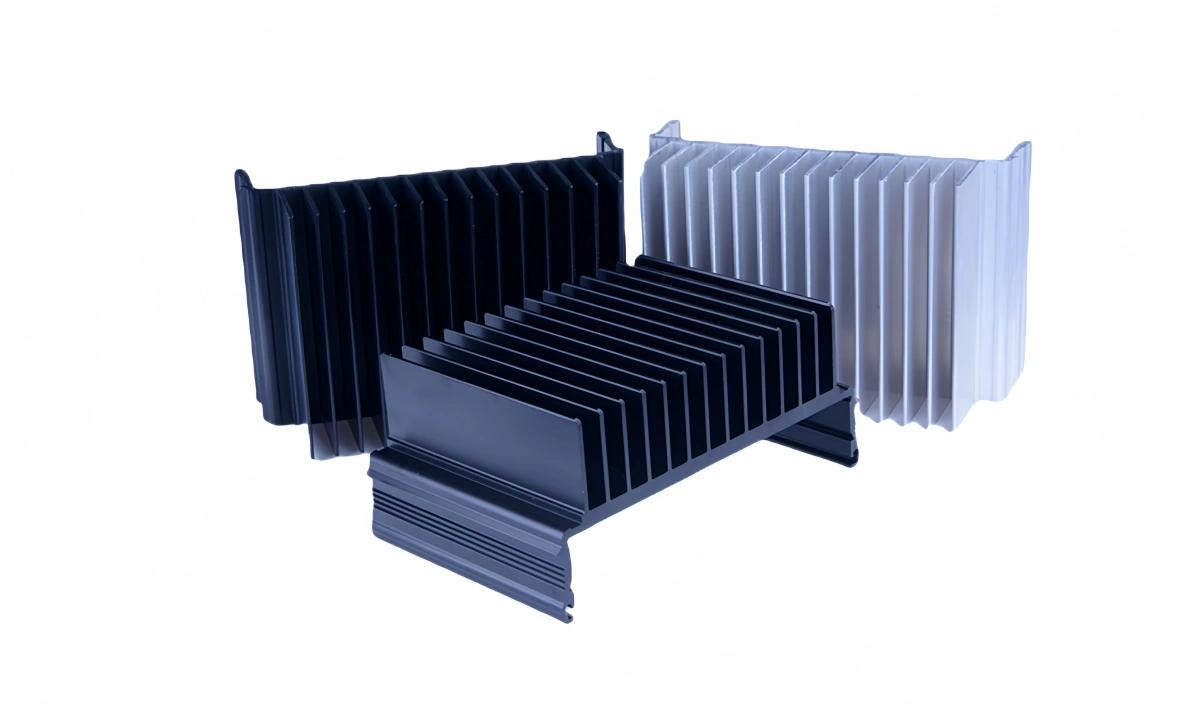

A great thing I tell my clients is that almost any profile can be a black aluminum extrusion. The black finish is a secondary process applied after we extrude the aluminum into whatever shape you need, whether it’s a standard channel or a complex custom design.

This is a key point that gives engineers and product designers incredible freedom. You are not limited to a small selection of pre-finished shapes. Instead, you design the perfect profile for your application first, and then we apply the finish. This two-step approach unlocks endless possibilities.

The process flow is simple:

This means you can get any standard profile with a beautiful black finish. This includes common shapes like T-slots for building machine frames, U-channels for edging, angles for brackets, and both round and square tubes. A black finish on these standard profiles elevates their appearance from industrial to high-end.

More importantly, you can create a completely custom black aluminum extrusion. This is where we provide the most value. We created a custom profile for a manufacturer of high-end display systems. The profile had to hold a glass panel, act as a heat sink for internal LEDs, and have a hidden channel for wiring. We designed the complex die, extruded the profile from 6063 alloy for its excellent surface quality, and then applied a matte black anodized finish. The final part was strong, multi-functional, and had the discreet, professional look their premium product required. This process of combining multiple functions into a single extrusion simplifies assembly and reduces overall costs.

Choosing the right black aluminum extrusion comes down to the process and details. Anodizing offers the best durability and look, transforming any profile into a premium, lasting component.