Indirizzo

304 Nord Cardinale

St. Dorchester Center, MA 02124

Orario di lavoro

Da lunedì a venerdì: dalle 7.00 alle 19.00

Fine settimana: 10.00 - 17.00

Indirizzo

304 Nord Cardinale

St. Dorchester Center, MA 02124

Orario di lavoro

Da lunedì a venerdì: dalle 7.00 alle 19.00

Fine settimana: 10.00 - 17.00

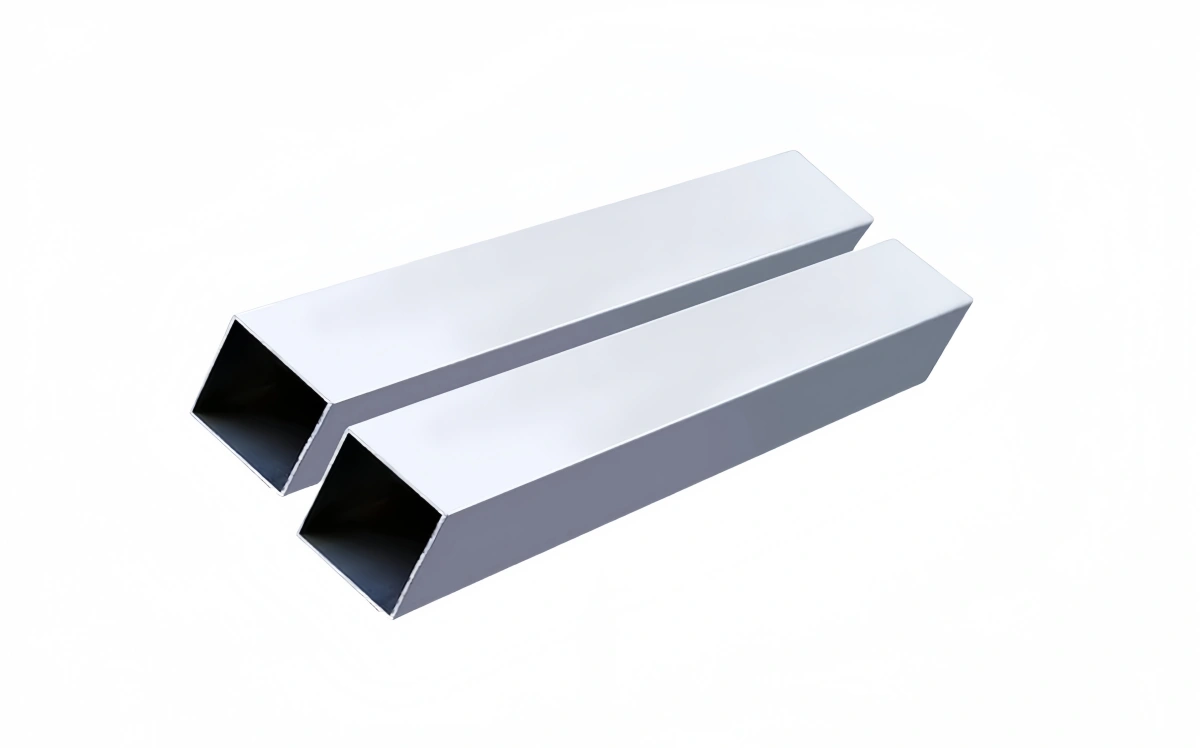

Tired of designs compromised by weak or heavy materials? These flaws can ruin a great project. I’ve found a game-changing secret for achieving flawless results: the aluminum extrusion square tube.

From my perspective, it’s a game-changer because it allows for flawless designs that are both incredibly strong and lightweight. I’ve personally used this “secret” to help clients create precise, durable products that were previously impossible with other materials, fundamentally improving their final design.

The aluminum extrusion square tube has so much to offer. Let’s break down exactly what makes this profile special and how it can benefit your next project. We will explore its unique features, the manufacturing process, its core advantages, and how to choose the right alloy for your needs.

Think all metal tubes are the same? That common mistake can be very costly. I’ve learned that the unique properties of an aluminum extrusion square tube can make all the difference in a project’s success.

From my perspective as a manufacturer, what makes it truly unique is the combination of its hollow, uniform profile and the extrusion process itself. This gives the aluminum extrusion square tube exceptional torsional strength while remaining incredibly lightweight, a combination that I find is rare in other materials.

When my clients in the United States and Europe ask what sets this product apart, I explain that it’s not just a piece of metal; it’s an engineered solution. Understanding these distinctions is crucial for any purchasing manager looking to source the best possible materials.

Many of my clients initially compare it to welded steel tubing. They soon realize that the seamless, monolithic structure of an aluminum extrusion square tube offers superior performance in applications requiring precision and stability.

The smooth, clean surface finish straight from the die is another feature that sets it apart, often reducing the need for costly secondary finishing operations. This inherent quality is a direct result of the extrusion process itself. An aluminum extrusion square tube isn’t just different; it’s fundamentally better for a wide range of modern applications.

The first thing to understand is the incredible strength-to-weight ratio. I once worked on a project for a client developing portable medical equipment. They initially used steel tubing, but the device was too heavy. By switching to a custom aluminum extrusion square tube, we reduced the frame’s weight by over 50% without compromising structural integrity. This is because the extrusion process creates a dense, uniform grain structure. This means you get the strength you need without the bulk, leading to lower shipping costs. An aluminum extrusion square tube provides this benefit without fail.

Second, the extrusion process delivers amazing consistency. Every aluminum extrusion square tube we produce from a specific die has the exact same dimensions. This precision is critical for manufacturing. For clients creating modular display systems, this uniformity means every part fits perfectly during assembly. There are no surprise gaps. This level of precision, which is a hallmark of a well-made aluminum extrusion square tube, means fewer rejections during your quality control checks, preventing costly production delays.

Finally, aluminum naturally protects itself by forming a thin, tough layer of aluminum oxide. This layer prevents rust and corrosion. Unlike steel, an aluminum extrusion square tube can often be used in its raw state, even in damp environments. This natural benefit of an aluminum extrusion square tube translates to a longer product lifespan and lower maintenance costs.

| Feature Comparison | Aluminum Extrusion Square Tube | Standard Steel Square Tube |

| Weight | Lightweight and easy to handle | Heavy and bulky |

| Resistenza alla corrosione | High (forms a natural protective layer) | Low (prone to rust without coating) |

| Machinability | Excellent, easy to cut and drill | Good, but requires more force |

| Shipping Cost | Lower due to less weight | Higher due to more weight |

Ever wonder how a solid block of metal becomes a perfect, hollow tube? Not understanding this process can make it hard to specify your needs accurately. I’ve overseen this process countless times, so let me explain it simply.

I’ve seen it thousands of times in our factory. We start by heating a solid aluminum cylinder, called a billet. Then, we use a powerful hydraulic press to force it through a hardened steel die. This die is shaped to create the hollow square profile of the tube.

The process is like squeezing toothpaste from a tube, but it involves immense heat and pressure. Understanding the steps for creating an aluminum extrusion square tube is key for any purchasing manager.

The die itself is a masterwork of engineering. For a hollow shape, the die is a two-part system with a mandrel that forms the hollow interior. As the aluminum billet is pushed, it divides and flows around the mandrel’s supports and then re-welds itself seamlessly in the die chamber. The pressure is so immense that the aluminum atoms form a strong metallic bond, which is why the tube is seamless and uniform.

This specific technique is what guarantees a structurally sound aluminum extrusion square tube. The billet temperature, extrusion speed, and cooling rate are all tightly controlled. Any deviation can affect the final properties, so this precision control is what we, as a supplier, manage to ensure every piece meets your exact specifications.

Everything starts with a solid aluminum alloy billet. We heat it to around 450-500°C (850-930°F), making it soft and malleable.

The heated billet is pushed by a powerful ram through the steel die. To make an aluminum extrusion square tube, the die has a square opening with a central mandrel to create the hollow inside.

As the aluminum extrusion square tube emerges, it’s cooled rapidly with air or water to lock in its strength. It is then stretched to ensure it is perfectly straight.

The long extrusion is cut to the ordered lengths. For many alloys, the cut sections of the aluminum extrusion square tube are then put in an aging oven to achieve their full T5 or T6 temper strength.

You need a material that delivers on performance without breaking the bank. The wrong choice will hurt your budget and your product’s quality. I’ve seen the advantages of the aluminum extrusion square tube save projects time and time again.

From my daily work, the biggest advantages are its design flexibility and low long-term cost. I help clients create complex, custom shapes that are impossible with other methods, and its natural resistance to rust means less maintenance and a longer product life, which my clients value.

When you look beyond the initial price, the true value of an aluminum extrusion square tube becomes clear. It solves problems related to manufacturing, logistics, and product lifecycle.

One of the most overlooked advantages is its excellent thermal conductivity. An aluminum extrusion square tube is very effective at dissipating heat. I had a client in the electronics sector who designed a housing for an industrial computer using a custom profile with integrated fins. The housing itself became the heat sink, eliminating the need for a separate cooling fan. This reduced cost, noise, and another potential point of failure.

Furthermore, the machinability of aluminum is outstanding. It is easy to cut, drill, tap, and mill, which drastically reduces fabrication time and cost compared to steel. This means faster turnaround on your finished parts. This combination of benefits is what makes the aluminum extrusion square tube so powerful.

The extrusion process allows us to integrate features like screw channels and T-slots directly into an aluminum extrusion square tube profile. This eliminates extra parts and assembly steps.

The total cost of ownership for an aluminum extrusion square tube is often much lower than for steel.

| Advantage Summary | Impact for Purchasing Managers |

| Leggero | Lower shipping costs and easier manual handling during assembly. |

| Flessibilità del design | Reduces part count, simplifying inventory and assembly. |

| Corrosion Resistant | Longer product life with lower maintenance and warranty claims. |

| High Thermal Conductivity | Can double as a heat sink, eliminating extra components. |

| 100% Recyclable | Meets sustainability goals and has high scrap value. |

Confused by aluminum alloys like 6061 or 6063? Picking the wrong one can mean product failure. Based on years of sourcing materials for clients, I can clarify which alloy you actually need for the job.

In my experience, alloy choice is everything for an aluminum extrusion square tube. A 6061-T6 alloy, which I recommend for structural parts, is significantly stronger than a 6063-T5 alloy. This is because of its different chemical makeup and heat treatment, directly impacting the final strength and application of the square tube.

Choosing the right alloy is the most critical decision when specifying an aluminum extrusion square tube. A 6061 profile has more magnesium and silicon, allowing for significant strengthening. This makes it the go-to choice for load-bearing structures like machine frames or support beams. In contrast, a 6063 profile is optimized for a smoother surface finish, making it ideal for architectural applications where aesthetics are paramount.

As a purchasing manager, you must be precise. Simply asking for an “aluminum extrusion square tube” is not enough. You must specify both the alloy and the temper.

The temper is just as important. For instance, a 6061-T6 aluminum extrusion square tube has been fully heat-treated for maximum strength, making it much stronger than its 6061-T4 counterpart. Misunderstanding this can lead to ordering a product that is not fit for purpose, resulting in dangerous failures.

The temper (-T5, -T6) indicates the heat treatment process and final strength.

| Property Comparison | 6061-T6 Aluminum | 6063-T5 Aluminum |

| Tensile Strength | High (Approx. 45,000 psi / 310 MPa) | Medium (Approx. 27,000 psi / 186 MPa) |

| Primary Use | Structural applications, machine frames | Architectural, decorative, good finish |

| Finitura superficiale | Good | Excellent |

| Weldability | Good | Excellent |

Ultimately, understanding the aluminum extrusion square tube is key. From its unique properties to its alloy choice, this knowledge empowers you to make smarter purchasing decisions for your projects.