Indirizzo

304 Nord Cardinale

St. Dorchester Center, MA 02124

Orario di lavoro

Da lunedì a venerdì: dalle 7.00 alle 19.00

Fine settimana: 10.00 - 17.00

Indirizzo

304 Nord Cardinale

St. Dorchester Center, MA 02124

Orario di lavoro

Da lunedì a venerdì: dalle 7.00 alle 19.00

Fine settimana: 10.00 - 17.00

Are you worried that a standard, flimsy case will fail to protect your valuable components? This can lead to product returns, damage your reputation, and increase costs.

In my decades as a manufacturer, I’ve seen firsthand that an aluminum extrusion enclosure is the most reliable solution. It delivers a powerful combination of strength, light weight, and heat dissipation that plastic or sheet metal simply cannot match, ensuring your project’s success.

Now, let’s explore the specific benefits, customization possibilities, and robust protection that make this type of enclosure the superior choice for any serious engineering project.

Are your designs limited by the weaknesses of plastic cases? Heat buildup, cracking, and EMI interference are common problems that can lead to product failure and unhappy customers.

From my direct experience, the key benefits are outstanding strength without the weight, natural heat dissipation, and built-in EMI shielding. This means your electronics stay cooler, are better protected from interference, and are housed in a durable, professional-looking case.

The decision to use an aluminum extrusion enclosure is an investment in your product’s quality and longevity. As a purchasing manager, understanding these core advantages helps you justify your choice and communicate its value to your team. These are not just material properties; they are solutions to common engineering problems. Let’s look at each benefit in more detail.

One of the most impressive qualities of aluminum is its high strength-to-weight ratio. An aluminum extrusion enclosure can withstand significant shock and vibration, which is critical for industrial equipment or portable devices. Unlike plastic, it won’t become brittle or crack over time. We typically use alloys like 6063 for its excellent finish or 6061 for higher structural strength. This durability ensures your product is protected throughout its lifecycle, from shipping to end-use. The lightweight nature also provides a practical benefit: it reduces shipping costs, a detail every purchasing manager appreciates.

Heat is the enemy of electronics. Overheating can reduce performance and lead to component failure. An aluminum extrusion enclosure is an excellent thermal conductor, naturally pulling heat away from sensitive components like processors and power regulators. For applications that generate more heat, we can design the enclosure’s profile to include integrated heat sink fins. This eliminates the need for a separate heat sink, reducing your bill of materials and simplifying assembly. This built-in cooling capability is a significant advantage over insulating materials like plastic.

An aluminum extrusion enclosure acts as a Faraday cage, blocking electromagnetic interference (EMI) and radio-frequency interference (RFI). This is essential for ensuring your product passes regulatory testing (like FCC or CE) and functions reliably in environments with a lot of electronic noise. Furthermore, aluminum naturally creates a protective oxide layer on its surface, making it highly resistant to corrosion. For even greater protection, we can anodize the enclosure, which creates a hard, durable, ceramic-like surface.

| Caratteristica | Direct Benefit to Your Product |

| High Strength-to-Weight Ratio | Protects components while lowering shipping costs. |

| Excellent Thermal Conductivity | Prevents electronics from overheating, improving reliability. |

| Natural EMI/RFI Shielding | Ensures stable performance and helps meet regulations. |

| Inherent Corrosion Resistance | Provides a long-lasting, professional finish without rust. |

Have you ever been forced to compromise your design to fit an off-the-shelf box? This often results in wasted space, awkward component placement, and a product that looks unprofessional.

Absolutely. I’ve worked on countless custom projects, and this is where aluminum extrusion truly shines. We can create a unique enclosure from your drawings that includes integrated features like PCB slots, screw bosses, and even your company logo, all built directly into the profile.

Customization is not just about aesthetics; it’s about intelligent engineering and manufacturing efficiency. For a purchasing manager, a custom aluminum extrusion enclosure means a simplified supply chain, faster assembly, and a superior final product. Instead of buying a box and then modifying it, you receive a part that is purpose-built for your application. This level of integration is a core strength of the extrusion process.

The journey to a custom enclosure begins with your design. We take your CAD file and use it to machine a custom extrusion die from hardened H13 steel. While there is an initial investment in this die, it quickly pays for itself. The die can produce thousands of identical, precise profiles, ensuring perfect consistency across your entire production run. This process allows us to create complex internal and external features that would be impossible or extremely expensive to machine from a solid block of metal.

This is where you can achieve significant savings in assembly time and part count. We can design the aluminum extrusion enclosure with features like:

After extrusion, we perform any necessary secondary CNC machining. This includes cutting the enclosures to their precise length, drilling holes for connectors, milling openings for displays, and engraving logos. We deliver a component that is ready for your assembly line.

| Customization Option | Benefit for Your Production |

| Custom Profile Shape | Enclosure perfectly matches your product’s form factor. |

| Integrated PCB Guides | Reduces assembly time and eliminates extra hardware. |

| CNC Machined Cutouts | Arrives ready for component installation with no extra steps. |

| Custom Anodizing/Coating | Delivers a unique look and feel with your brand’s colors. |

Are you wondering if this type of enclosure is the right fit for your specific industry or product? It can be hard to visualize the possibilities if you’ve only seen them in one context.

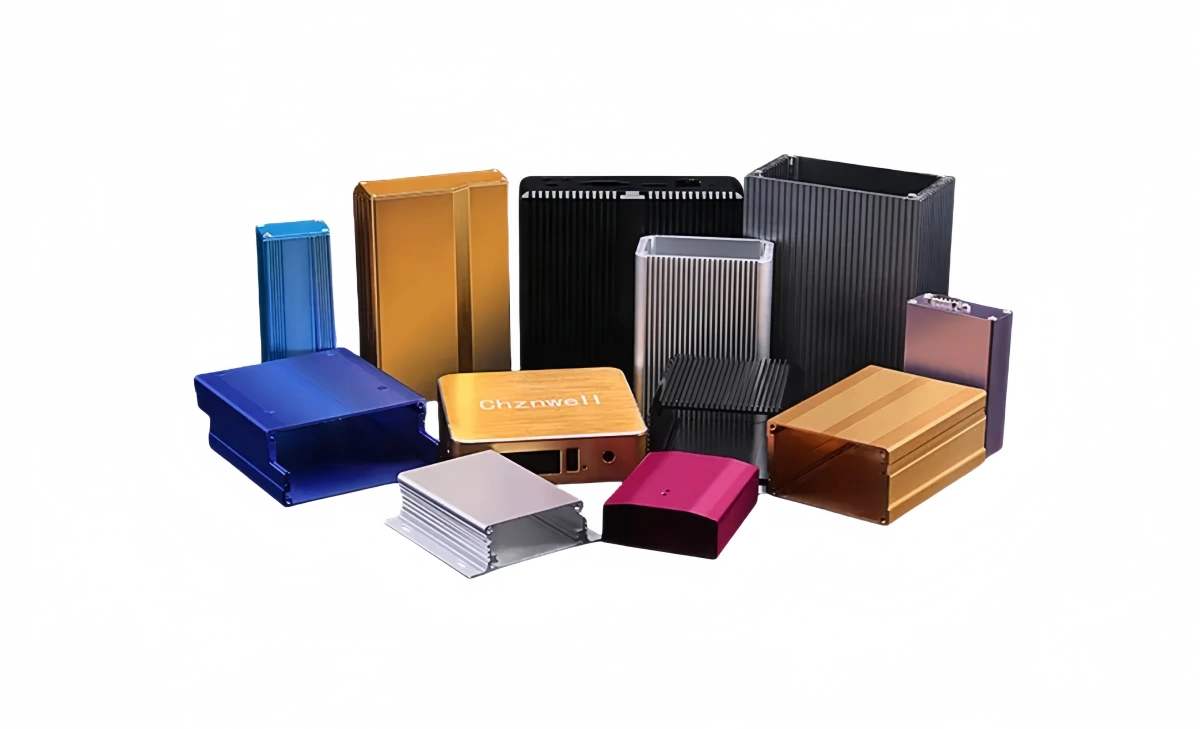

In my factory, I see an incredible variety of uses every day. An aluminum extrusion enclosure is a workhorse in industries from telecommunications and industrial automation to consumer electronics and medical devices. Their versatility is one of their greatest strengths.

The wide range of applications for an aluminum extrusion enclosure stems from its unique combination of benefits. Different industries prioritize different features—some need ruggedness, some need thermal management, and others need a sleek, professional look. The ability to customize the enclosure allows it to meet these diverse needs effectively. Let’s look at a few key examples.

In a factory setting, electronic components are exposed to vibration, dust, and electrical noise. An aluminum extrusion enclosure is ideal for housing PLC controllers, power converters, and sensor modules. Its physical strength protects against impact, while its EMI shielding ensures that the control signals remain clean and reliable. We can also machine them to fit standard DIN rails for easy installation in control cabinets.

Both high-power LED lights and audio amplifiers generate a lot of heat. An aluminum extrusion enclosure with integrated heat sink fins is the perfect solution. It provides a robust housing and a cooling system in a single component. This leads to a more compact design and ensures the longevity of the LEDs or audio components. For high-end audio, the material’s rigidity also helps to reduce microphonic vibrations.

These applications demand precision, reliability, and a clean, professional appearance. An aluminum extrusion enclosure provides the necessary EMI shielding to protect sensitive measurement circuits from outside interference. The smooth, anodized finish is also easy to clean and resistant to chemicals, which is often a requirement in laboratory or medical environments. Its durability ensures that expensive portable test equipment can withstand the rigors of field use.

| Industria | Primary Reason for Using an Aluminum Enclosure |

| Industrial Automation | Durability, EMI shielding, and resistance to harsh environments. |

| LED Lighting | Superior heat dissipation to ensure LED longevity and performance. |

| Consumer Electronics | Sleek, professional appearance and a high-quality feel. |

| Medical & Lab Equipment | EMI protection, chemical resistance, and ease of cleaning. |

You need absolute confidence that your product will survive in its intended environment. A weak enclosure means a vulnerable product, leading to costly failures and a damaged brand reputation.

From an engineering perspective, I can assure you they are exceptionally protective. An aluminum extrusion enclosure provides a multi-layered defense system against physical shock, environmental hazards like dust and water, and disruptive electronic interference.

The term “protection” covers several key areas. It’s not just about being a strong box. A truly protective enclosure guards the components inside against a range of threats. An aluminum extrusion enclosure excels in all these areas, providing peace of mind that your design is secure. This is a critical point for purchasing managers, as a field failure due to inadequate protection can have severe financial consequences.

The inherent strength of extruded aluminum provides a very high level of physical protection. Compared to molded plastic, it is far more resistant to cracking from impacts or drops. The rigid structure also prevents flexing, which could damage solder joints on the circuit board inside. For applications requiring even greater strength, we can use higher-strength alloys like 6061-T6. This makes the aluminum extrusion enclosure a superior choice for any device that will be handled frequently or used in a demanding physical environment.

For products that will be used outdoors or in dusty/damp indoor environments, protection from particle and moisture ingress is critical. We can design an aluminum extrusion enclosure to meet specific Ingress Protection (IP) ratings. By using custom gaskets in precisely engineered channels and ensuring tight tolerances between the enclosure body and end plates, we can achieve ratings like IP65 (dust-tight and protected from water jets) or even higher. This level of environmental sealing is essential for ensuring product reliability and longevity in anything other than a clean office environment.

As discussed earlier, an aluminum extrusion enclosure provides excellent EMI/RFI shielding. This protects your device from malfunctioning due to external noise and prevents your device from emitting noise that could interfere with other nearby electronics. This is not a “nice-to-have” feature; for many products, it is a requirement to achieve regulatory certification. At the same time, its thermal conductivity protects components from another threat: their own heat. By efficiently dissipating heat, the enclosure prevents thermal damage and ensures all components operate within their safe temperature range.

An aluminum extrusion enclosure delivers superior protection, deep customization, and a premium finish. It is a smart, reliable investment that ensures your product’s quality and enhances your brand’s reputation.