Indirizzo

304 Nord Cardinale

St. Dorchester Center, MA 02124

Orario di lavoro

Da lunedì a venerdì: dalle 7.00 alle 19.00

Fine settimana: 10.00 - 17.00

Indirizzo

304 Nord Cardinale

St. Dorchester Center, MA 02124

Orario di lavoro

Da lunedì a venerdì: dalle 7.00 alle 19.00

Fine settimana: 10.00 - 17.00

As a buyer, have you ever faced endless headaches with product quality and delivery? I’ve seen how poor design choices can completely derail projects.

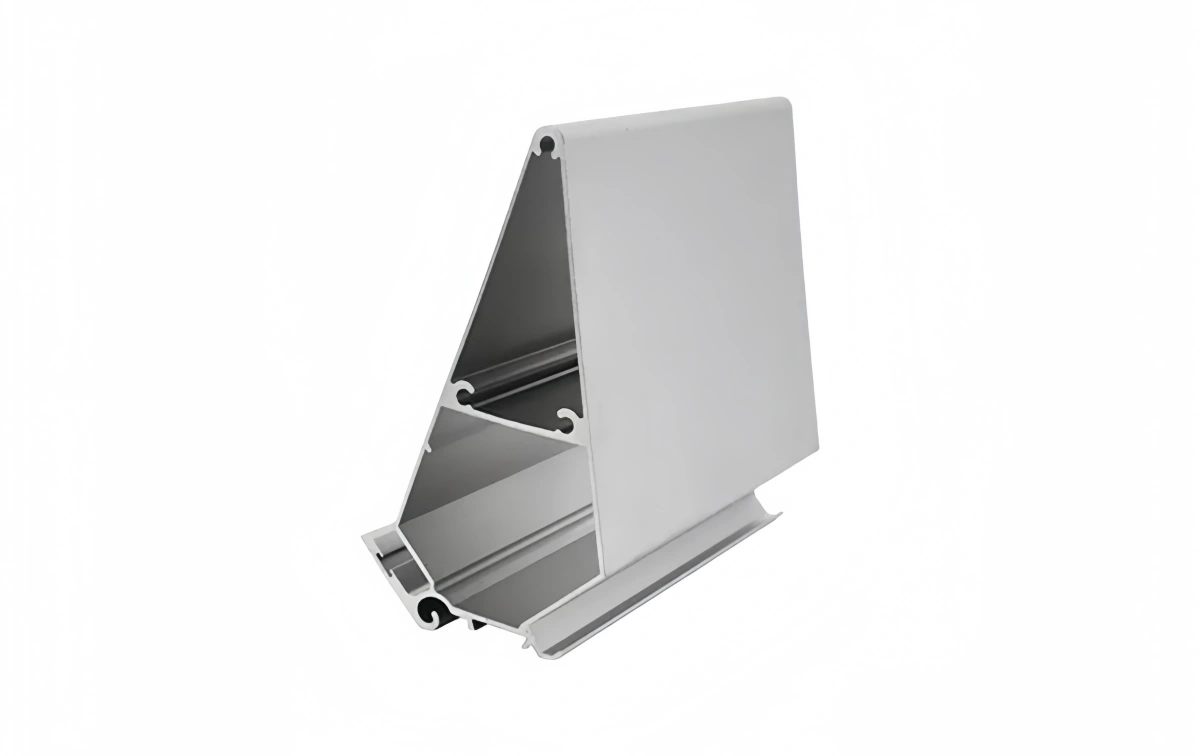

Aluminum extrusion design is an incredibly powerful process. It shapes raw aluminum into specific cross-sectional profiles. This method is vital for creating complex, custom parts that are both lightweight and strong. It’s a key step in manufacturing various industrial and consumer products.

Let’s dive deeper. Understanding this process can save you time and money. It also helps you get better products.

Have you ever wondered what makes certain products so light yet durable? I often think about the many ways aluminum extrusions improve daily life.

Aluminum extrusion design is used across many industries. It creates parts for aerospace, automotive, construction, and electronics. Common applications include window frames, heat sinks, structural components, and custom enclosures for various devices and machines.

Aluminum extrusion design plays a big role in many industries. It is not just for one type of product. For example, in the building industry, extrusions form frames for windows and doors. They also make curtain walls and structural supports. These parts are strong and resist weather well. This makes buildings last longer.

In the car industry, aluminum extrusions make car parts lighter. This helps cars use less fuel. Parts like chassis components and trim pieces use this method. Lighter cars also perform better. This is important for both regular cars and electric vehicles.

Electronics also use aluminum extrusion design. Heat sinks are a good example. They draw heat away from electronic parts. This stops devices from getting too hot and breaking. Extruded aluminum cases also protect sensitive electronics. They keep dust and water out.

We also see extrusions in solar panel frames. They give strength to the panels. They also help with easy installation. Furniture often uses extruded aluminum too. It makes strong and light frames for chairs and tables. Even in medical equipment, you can find extruded aluminum parts. They need to be precise and clean.

The beauty of aluminum extrusion design is its flexibility. You can make almost any shape. This is good for custom projects. It lets engineers solve complex problems with unique parts. It helps make products better and cheaper. This is why many buyers look for suppliers who are good at extrusion design.

| Industria | Common Uses of Aluminum Extrusion Design | Vantaggi |

| Construction | Window frames, door frames, structural supports, curtain walls | Strength, weather resistance, durability |

| Automotive | Chassis components, trim, engine parts, battery enclosures | Lightweight, fuel efficiency, improved performance |

| Elettronica | Heat sinks, device casings, enclosures | Thermal management, protection, aesthetics |

| Solar | Panel frames, mounting systems | Structural integrity, ease of installation |

| Furniture | Table legs, chair frames, display units | Lightweight, modern aesthetics, durability |

Have you ever wondered how aluminum gets its precise shape? I find the transformation from raw material to finished product quite amazing.

Aluminum extrusion design involves pushing heated aluminum through a die. This die has a specific shape. The aluminum takes on this shape as it comes out. It then cools and hardens. This process allows for complex cross-sections and constant profiles along the length of the material.

Understanding how aluminum extrusion design works helps you get the best parts. First, we start with an aluminum billet. This is a solid cylinder of aluminum. We heat this billet to a high temperature, usually around 450 to 500 degrees Celsius. Heating makes the aluminum soft enough to push through a die.

Next, we load the heated billet into an extruder. A hydraulic ram then pushes the billet. It pushes it through a die. The die is a tool steel block with a shaped opening. This opening is the exact cross-section of the final part. As the aluminum passes through the die, it takes its shape. This is like squeezing toothpaste from a tube.

After the aluminum comes out of the die, it is still hot. It is then pulled along a run-out table. Here, it cools down. Cooling helps the aluminum harden and keep its new shape. Sometimes, fans or water are used to speed up this cooling.

Once cool, the extruded profile is stretched. This stretching helps to remove any twists or bends that happened during extrusion. It also improves the straightness of the profile. Then, we cut the long extruded lengths into smaller, manageable pieces. These pieces are then heat-treated. Heat treatment makes the aluminum stronger and harder. It improves the mechanical properties of the material. This final step is crucial for the overall strength and durability of the aluminum parts. Good aluminum extrusion design relies on careful control at each of these stages.

| Stage | Descrizione | Scopo |

| Billet Heating | Aluminum cylinder heated to specific temperature | Softens metal for extrusion |

| Estrusione | Ram pushes billet through a die | Shapes aluminum to desired profile |

| Cooling | Profile cools on run-out table | Hardens and sets the shape |

| Stretching | Profile is pulled to remove deformations | Ensures straightness and dimensional accuracy |

| Cutting | Long profiles cut into shorter lengths | Prepares for further processing |

| Heat Treatment | Profiles undergo a controlled heating and cooling cycle | Increases strength and hardness |

Have you ever wondered how to get the most out of your aluminum parts? I often think about how to make designs more efficient and cost-effective.

To optimize aluminum extrusion design, focus on simplifying profiles, reducing wall thickness where possible, and using standard alloys. Consider the die design carefully to avoid complex shapes that increase costs. Also, plan for secondary operations to minimize extra steps. This ensures a more efficient and economical production.

Optimizing aluminum extrusion design is about getting the best performance at the lowest cost. One main way is to keep the profile simple. Complex shapes need more complicated dies. These dies cost more to make and maintain. Simpler designs also reduce the chances of errors during production. They often lead to faster extrusion speeds too.

Another important point is wall thickness. Thinner walls use less material. This means lower material costs. However, walls must be thick enough for the part to be strong. Finding the right balance is key. Very thin walls can be hard to extrude without problems. Working with an experienced supplier helps here. They can advise on the best thickness for your needs.

Choosing the right aluminum alloy is also vital. Different alloys have different properties. Some are stronger, some are more corrosion resistant. Others are easier to extrude. For example, 6061 and 6063 are common alloys for extrusion. They offer a good balance of strength and formability. The choice of alloy impacts the final product’s performance and cost.

Think about secondary operations early in the aluminum extrusion design process. Secondary operations are steps like cutting, drilling, or bending after extrusion. If you design the extrusion to include features that reduce these steps, you save money. For example, you can design a profile with built-in channels for fasteners instead of drilling them later. This makes the overall manufacturing process more efficient. Also, consider the tolerance requirements. Tighter tolerances usually mean higher costs. Design for the widest acceptable tolerances to save money without affecting function. Work closely with your supplier to review your aluminum extrusion design. They can suggest changes that improve efficiency and reduce costs.

| Optimization Area | Descrizione | Benefici |

| Profile Simplicity | Avoid overly complex shapes and sharp corners | Lower die costs, faster production, fewer errors |

| Wall Thickness | Balance strength with material usage; avoid extreme thinness | Reduced material cost, acceptable part strength |

| Alloy Selection | Choose alloys suitable for application and extrusion process | Optimal performance, cost-effectiveness |

| Secondary Operations | Design features that reduce need for post-extrusion work | Lower overall manufacturing cost, faster lead times |

| Tolerance Review | Design for widest acceptable tolerances | Reduced production difficulty and cost |

Have you ever wondered what new things are happening in the world of aluminum extrusions? I am always curious about how technology pushes boundaries.

Innovations in aluminum extrusion design focus on advanced die materials, smarter process controls, and the use of more complex alloys. There are also new techniques for creating intricate hollow profiles and integrating multiple functions into single extrusions. These advancements help make stronger, lighter, and more versatile aluminum products.

The field of aluminum extrusion design is always changing. New innovations make it possible to create even better parts. One big area of change is in die technology. New materials for dies make them stronger and last longer. This means they can handle more complex shapes and higher production volumes. Also, better manufacturing methods for dies, like additive manufacturing, allow for more intricate designs that were not possible before.

Another innovation is in smart process control. Modern extrusion presses use sensors and computer systems. These systems monitor the temperature, pressure, and speed during extrusion. They can make real-time adjustments. This leads to more consistent product quality. It also reduces waste and improves efficiency. Smart controls help achieve tighter tolerances. This is very important for demanding applications.

New alloys are also changing aluminum extrusion design. Researchers are developing alloys that are stronger, lighter, or more resistant to corrosion. For instance, some new alloys offer very high strength-to-weight ratios. These are perfect for aerospace and automotive parts. Others provide better thermal conductivity for heat management applications. These advanced materials give designers more options.

We also see innovations in creating multi-functional extrusions. This means designing a single aluminum part that does several jobs. For example, an extrusion might have channels for wiring, mounting points, and heat dissipation fins all in one piece. This reduces assembly time and the number of separate parts needed. It simplifies the overall product design. Hollow profiles with complex internal geometries are also becoming more common. These can be lighter and just as strong as solid parts. They also offer internal pathways for fluids or cables. These innovations in aluminum extrusion design allow for more advanced products. They help manufacturers meet new demands in many industries.

| Innovation Area | Descrizione | Impact on Aluminum Extrusion Design |

| Advanced Die Technology | Stronger, more durable die materials and manufacturing | Allows for more complex shapes, higher volumes |

| Smart Process Control | Real-time monitoring and adjustment during extrusion | Improved quality, tighter tolerances, reduced waste |

| New Aluminum Alloys | Development of stronger, lighter, or specialized alloys | Expanded design possibilities, enhanced product performance |

| Multi-functional Extrusions | Integrating multiple features into a single profile | Reduced assembly time, fewer parts, simplified design |

| Complex Hollow Profiles | Creating intricate internal geometries | Lighter parts, integrated channels for utilities |

Aluminum extrusion design is critical for quality and cost. Focus on simple profiles, material choice, and planned secondary ops. These steps help make strong, light, and effective parts.