Indirizzo

304 Nord Cardinale

St. Dorchester Center, MA 02124

Orario di lavoro

Da lunedì a venerdì: dalle 7.00 alle 19.00

Fine settimana: 10.00 - 17.00

Indirizzo

304 Nord Cardinale

St. Dorchester Center, MA 02124

Orario di lavoro

Da lunedì a venerdì: dalle 7.00 alle 19.00

Fine settimana: 10.00 - 17.00

Are you tired of slow metal part creation? Frustrated by high costs and project delays? I know I was, until I truly understood the power of CNC punching services for specific applications.

From my experience, CNC punching services are indeed an incredible solution for many metal fabrication projects. They offer remarkable speed, good precision, and cost-effectiveness, especially for parts with numerous holes or standard shapes. We utilize them effectively in our factory.

But what exactly are these services, and how can they truly benefit your business’s bottom line? Let’s explore this further. You might be surprised by what you learn and how CNC punching services could streamline your production.

Confused about what CNC punching services truly mean for your projects? Wondering if it’s just another complex industry buzzword? I get it; let’s clear things up simply and explain how we see it.

In my view, CNC punching services are a subtractive manufacturing process. A specialized machine uses a punch and die tool set to create precise holes and forms in sheet metal, all meticulously controlled by a computer program. It’s a highly automated and accurate method.

When we talk about CNC punching services, we’re referring to a sophisticated method of shaping sheet metal. “CNC” stands for Computer Numerical Control. This means a computer program dictates the machine’s movements and operations, rather than manual control. This automation is key to the precision and repeatability that these services offer.

The core of the process involves a punch and a die. The punch is a hardened tool, shaped to create the desired hole or form. The die supports the metal sheet and has a corresponding opening for the punch. The machine then forcefully presses the punch through the metal and into the die. This action shears the material, creating the feature.

Think of it like a very powerful and precise hole puncher. However, it can also create other shapes and even some three-dimensional forms, like louvers or dimples. The machines used for these services are often called turret punch presses. These can hold a variety of tools (punches and dies) in a rotating turret.

The CNC program selects the correct tool for each feature. It also moves the metal sheet into the correct position and then activates the punching action. This ability to quickly change tools and accurately position the material makes CNC punching services incredibly versatile. For our clients at ALUT, this means we can produce complex patterns of holes and forms efficiently. This is essential for many customized aluminum products we manufacture. The entire process, from loading the sheet metal to the final punched part, is designed for speed and accuracy. This makes CNC punching services a valuable part of modern metal fabrication.

To really understand CNC punching services, it helps to know the main parts of the system. Each component plays a vital role in the overall process, ensuring accuracy and efficiency.

| Component | Function | Importance for CNC Punching Services |

| CNC Controller | The “brain”; reads program (G-code), sends instructions to motors and tooling. | Ensures precise execution of the design. |

| Punch Press Machine | The “brawn”; includes frame, punching mechanism (ram), sheet holding/moving system. | Provides the force and structure for punching. |

| Turret/Tool Changer | Holds multiple punch/die sets; rotates to select the correct tool. | Allows for diverse shapes in one setup. |

| Workpiece Clamps | Securely hold and accurately move the sheet metal under the punching station. | Critical for positional accuracy of features. |

Our engineers program the CNC controller carefully for each custom part we make. The punch press machine provides the necessary force, while the turret allows for quick tool changes. Accurate workpiece clamps are vital for the quality of the final part, a key aspect of our CNC punching services.

The journey from an idea to a finished component using CNC punching services typically follows clear steps. This systematic approach ensures quality and efficiency.

Understanding these components and steps helps appreciate the efficiency and precision that CNC punching services bring to metal fabrication.

Curious about the mechanics behind the machine? How does a flat sheet of metal transform into a complex part with such accuracy? I was fascinated when I first saw the detailed process in action at our facility.

From what I’ve observed daily in our factory, CNC punching services operate through a precise G-code program. This specialized code directs the machine on where to move the sheet metal and which specific tool to select from its turret to punch exact holes or forms.

The operation of CNC punching services is a well-orchestrated sequence of events, all driven by that digital G-code. Once the sheet metal is loaded and clamped securely onto the machine’s bed, the CNC controller takes over.

The G-code contains coordinates, typically X and Y axes, for every feature to be punched. It also includes commands for tool selection. The machine’s clamps, driven by servo motors, move the sheet metal rapidly and precisely under the punching head. Simultaneously, if a different tool is needed, the turret (a rotating carousel holding multiple punch and die sets) spins to position the correct tool above the die.

When the sheet is in place and the correct tool is selected, the ram is activated. The ram is the part of the machine that pushes the punch. It drives the punch with significant force through the material and into the die below. The small piece of removed material, called a slug, falls through the die.

This process repeats for every hole or feature defined in the G-code. For parts requiring many identical holes, CNC punching services are exceptionally fast. The machine can make repeated hits, a “nibbling” process for slots or large openings, or single hits very quickly. The speed of the table movement and the punching action (strokes per minute) are key performance indicators for these machines. Modern CNC punching services also incorporate features like automatic tool lubrication. Some even have automated loading and unloading systems to further enhance efficiency and reduce manual intervention. This is something we continuously evaluate for our operations.

G-code is the fundamental language that tells the CNC punch press what to do. Each line of code typically specifies several key instructions.

Our programmers ensure the G-code is optimized. This means the fastest production path and minimal tool changes, which is crucial for efficient CNC punching services.

The turret is a critical component of most CNC punch presses. It’s a circular or linear magazine that holds a variety of punch and die sets.

Efficient material handling is key to maximizing the output of CNC punching services.

The seamless integration of these elements – precise G-code, versatile tooling, and efficient material handling – is what makes CNC punching services a highly productive manufacturing method.

Is CNC punching truly worth considering for your specific projects? What really makes it stand out from other fabrication methods? I’ve seen firsthand the substantial benefits it brings to our clients’ designs and their production efficiency.

The key advantages I consistently see with CNC punching services are their incredible speed for repetitive tasks, significantly lower tooling costs compared to stamping for moderate production volumes, and reliably good accuracy. It’s fantastic for creating many holes and simple forms quickly.

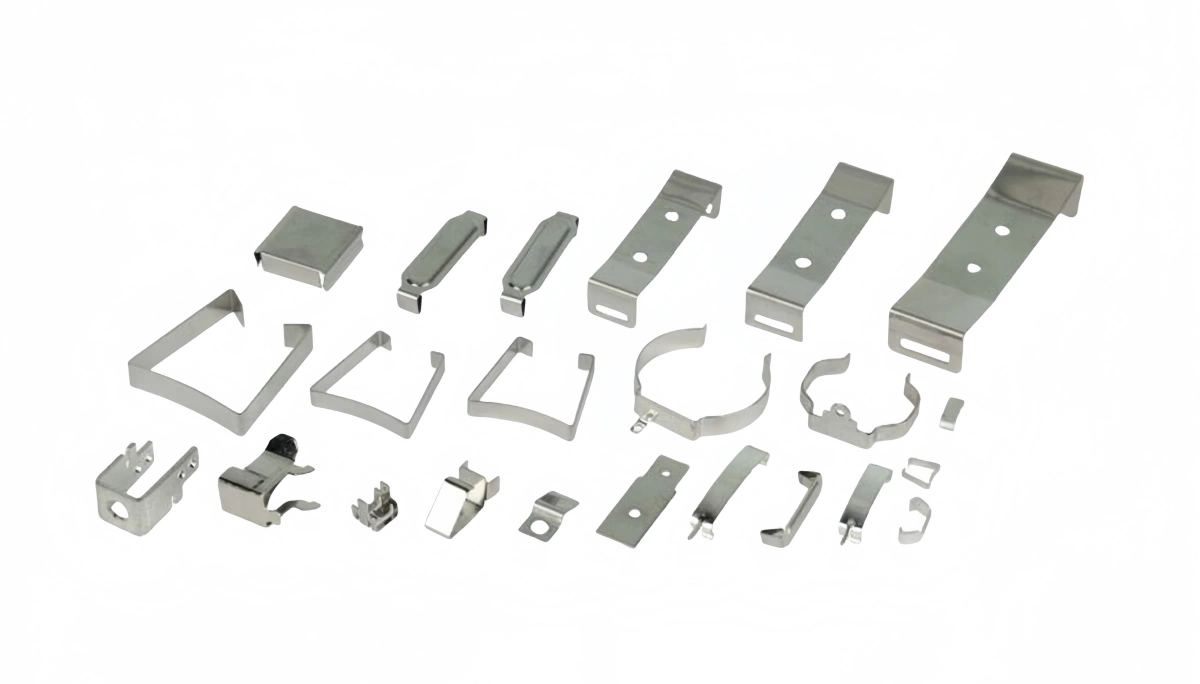

When evaluating manufacturing methods, the advantages of CNC punching services become very clear, especially for certain types of parts. One of the most significant benefits is speed and efficiency. This is particularly true when a part requires a large number of holes or standard shapes. A CNC punch press can make hundreds of hits per minute. For components like enclosures, panels, or brackets with multiple perforations, CNC punching services are often much faster than drilling each hole individually or using a laser cutter for simple round holes. This speed translates directly into lower per-part costs and shorter lead times, which is something our customers at ALUT highly value.

Another major advantage is tooling cost. While the CNC punch press itself is a significant investment for us as a provider, the individual punch and die sets are relatively inexpensive and often standardized. This is a stark contrast to hard tooling for stamping. Stamping involves creating dedicated, complex dies that can cost tens of thousands of dollars. For low to medium volume production runs, or for projects where design changes are anticipated, the lower tooling investment of CNC punching services makes it a very attractive option.

Beyond just making holes, modern CNC punching services offer impressive versatility. This means they can do more than just basic punching.

This capability to combine punching and forming in a single setup within our CNC punching services can eliminate the need for secondary operations. This saves time and money for our clients.

CNC control ensures a high degree of accuracy and repeatability. Once the program is set and the machine is calibrated, each part produced will be virtually identical. This consistency is crucial for assembly and for maintaining quality standards, a cornerstone of the CNC punching services we provide. Typical tolerances for CNC punching are quite good. They are often in the range of +/- 0.1mm to +/- 0.25mm, depending on the material and thickness.

It’s helpful to see how CNC punching services compare to other common sheet metal fabrication processes. Each method has its strengths and is suited for different applications.

| Caratteristica | CNC Punching Services | Laser Cutting | Stamping |

| Costo degli utensili | Low to Moderate | None (no dedicated tooling per part) | Very High |

| Parte Complessa | Good for holes, standard shapes, some forms | Excellent for intricate contours | Best for high volume of identical parts |

| Speed (Holes) | Very Fast | Moderate to Fast | Extremely Fast (in production) |

| **Speed (Contours) | Moderate (nibbling) | Very Fast | N/A (die defines contour) |

| Edge Quality | Good, can have slight burr/scallop | Excellent, smooth edge | Good to Excellent (depends on die) |

| Material Thickness | Typically thinner gauges (<6mm steel) | Wider range, including thicker plates | Wide range, depends on press tonnage |

| Heat Affected Zone | No | Yes, minimal with modern lasers | No |

| Ideal Volume | Low to Medium | Prototype to Medium | High to Very High |

This comparison shows that CNC punching services have a distinct place. They are especially valuable when cost-effectiveness for parts with many standard features is paramount.

Can any type of metal be effectively shaped using this method? Or are there specific limitations to consider for project success? This is a crucial question I always discuss in detail with our clients at ALUT.

In our extensive experience providing CNC punching services, common materials like various grades of aluminum, mild steel, and stainless steel work very well. The material’s overall thickness and its inherent hardness are key factors we always carefully consider to ensure optimal results and tool life.

The suitability of a material for CNC punching services depends on several factors. Primarily, these are its mechanical properties and thickness. Generally, materials that are ductile enough to be sheared cleanly without excessive cracking or tool wear are preferred.

At ALUT, we routinely work with a range of metals. Understanding their behavior during punching is critical to delivering quality customized aluminum products and other metal parts. The force required to punch a material is directly related to its shear strength and thickness, and also the perimeter of the punch. Our machines are rated for a certain tonnage. This limits the combination of material strength, thickness, and feature size we can process using our CNC punching services.

Overly hard or brittle materials can cause rapid tool wear or even tool breakage. They may also result in poor edge quality with micro-cracks. Very soft materials, on the other hand, might deform undesirably around the punched hole or lead to galling on the tooling. Therefore, selecting the right grade and temper of a material is as important as selecting the material type itself when planning for CNC punching services. We often advise clients on material choices to ensure manufacturability and part performance.

Here’s a look at some of the most common materials processed using CNC punching services:

Beyond the base material type, several other factors influence how well a material can be processed. Understanding these is key for successful CNC punching services.

| Fattore | Influence on Punching | Consideration for CNC Punching Services |

| Thickness | Major constraint; thicker materials require more force. Min. hole size related to thickness. | Best for sheet metal (<6mm steel). Limits punch diameter. |

| Hardness | Harder materials need more force, increase tool wear. | May require specialized tooling, slower speeds, more frequent tool changes. |

| Tensile Strength | Related to the force needed to shear the material. | Impacts machine tonnage requirements and tool life. |

| Ductility | Ability to deform without fracturing; crucial for clean shearing. | Low ductility can lead to cracking or poor edge quality. |

| Abrasiveness | Some materials/coatings wear down tools faster. | May necessitate harder tool materials or coatings. |

| Surface Finish Req. | Punching can leave a slight burr on one side. | Deburring might be needed if a perfectly smooth edge is critical. |

The general rule of thumb is that the minimum hole diameter should not be less than the material thickness, especially for harder materials. This helps to avoid punch breakage. Choosing the right material is a collaborative process. Our team at ALUT leverages its experience with CNC punching services to guide clients. We help them select materials that balance performance, cost, and manufacturability for their specific applications.

So, CNC punching services clearly offer a dynamic, versatile, and efficient method for manufacturing metal parts. If your projects demand quality, speed, and cost-effectiveness for features like holes and forms, they are absolutely worth exploring.