Indirizzo

304 Nord Cardinale

St. Dorchester Center, MA 02124

Orario di lavoro

Da lunedì a venerdì: dalle 7.00 alle 19.00

Fine settimana: 10.00 - 17.00

Indirizzo

304 Nord Cardinale

St. Dorchester Center, MA 02124

Orario di lavoro

Da lunedì a venerdì: dalle 7.00 alle 19.00

Fine settimana: 10.00 - 17.00

I know the frustration of sourcing materials that look good initially but fail after a few months. As a manufacturer, I see how poor material choices can ruin a project’s reputation.

An anodized aluminum plate is an aluminum sheet treated with an electrochemical process to thicken its natural oxide layer. This creates a hard, durable, and corrosion-resistant surface that integrates fully with the underlying metal, unlike surface paint.

If you want to reduce replacement costs and improve product quality, keep reading to understand why this material is crucial for your supply chain.

You might wonder how we transform soft metal into something so tough and visually appealing. The process is fascinatingly simple yet highly effective.

To create an anodized aluminum plate, we submerge the aluminum in an acid electrolyte bath and pass an electric current through it. This oxidizes the surface, turning it into a durable, decorative, and corrosion-resistant anodic oxide finish.

When I walk through our factory floor at ALUT, the anodizing line is always the busiest area. Understanding how we make an anodized aluminum plate helps you appreciate its value. It is not just a coating like paint; it is a transformation of the metal itself. We do not just spray something on top. We use science to change the surface structure.

Here is a simple breakdown of the process we use for every anodized aluminum plate:

Before anything happens, the aluminum must be spotless. We use alkaline and acid cleaners to remove grease, oil, and dirt. If we skip this, the final look will be uneven. I always tell my team that 90% of a good finish comes from good cleaning.

Next, we decide the texture. Etching gives a matte finish, hiding small defects. Brightening makes it shiny. Most of my clients in the machinery sector prefer a matte finish because it looks professional and hides fingerprints.

This is the core step. We place the metal into a tank filled with acid and water. We run electricity through the tank. The aluminum acts as the anode. Oxygen ions serve as the cathode. These ions combine with the aluminum atoms to build a strong oxide layer.

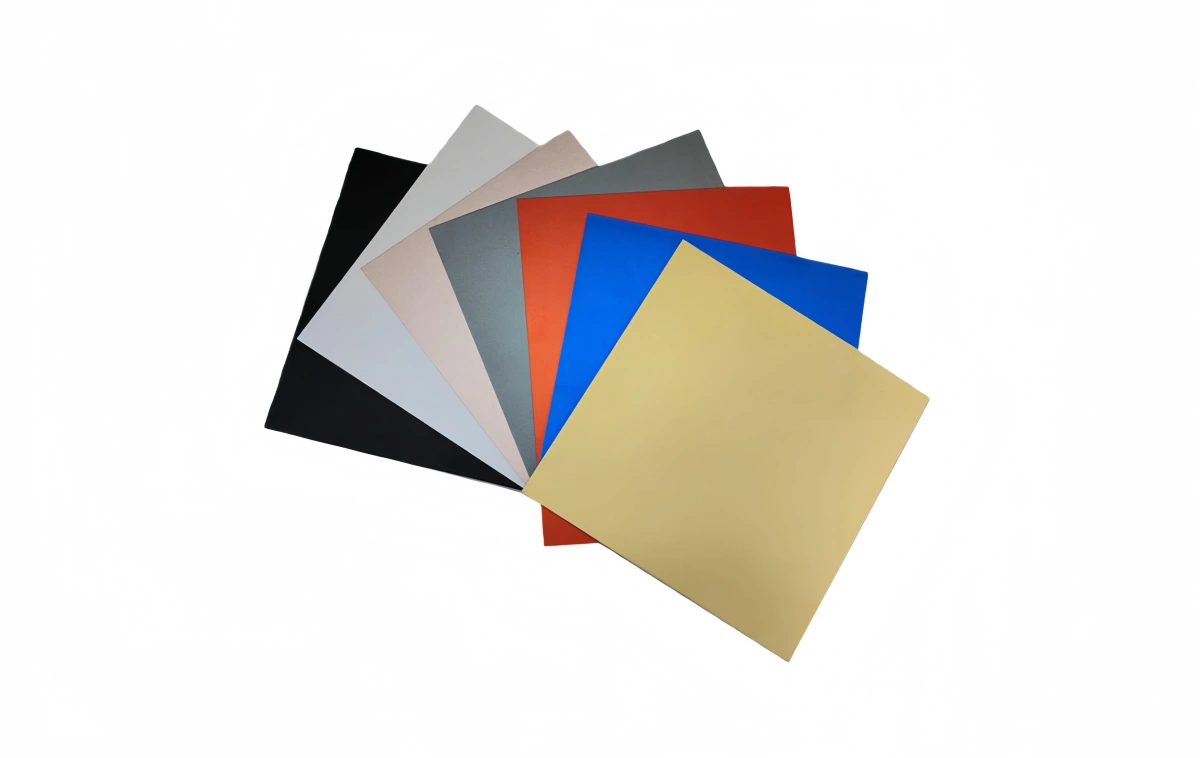

The porous structure of the new layer can absorb dye. We can make the anodized aluminum plate black, red, blue, or gold. The dye goes into the pores, so it does not chip off easily.

This is the most critical step for durability. We close the pores using hot water or steam. This locks in the color and prevents corrosion. If a supplier skips this, your product will fade.

Below is a table showing the different types of anodizing we can do:

| Type | Descrizione | Best Use |

| Type I (Chromic Acid) | Creates a thin, opaque film. | Aerospace parts requiring fatigue resistance. |

| Type II (Sulfuric Acid) | The most common method. Good thickness and color options. | General industrial parts, architecture. |

| Type III (Hard Coat) | Extremely thick and hard layer. | Heavy machinery, gears, military equipment. |

At ALUT, we ensure every anodized aluminum plate goes through strict quality control during these steps to meet your exact specifications.

Is there really a big difference between raw and treated aluminum? The answer affects your product’s lifespan and your company’s bottom line significantly.

The main difference is the surface protection. A regular sheet has a thin, natural oxide layer, while an anodized aluminum plate boasts a much thicker, engineered layer that resists wear, scratches, and corrosion far better than untreated metal.

I often have purchasing managers ask me if they can save money by buying raw aluminum. My answer is usually no, not if you care about quality. While raw aluminum has a natural oxide film, it is very thin and uneven. It offers some protection, but it is not enough for industrial use or outdoor products.

An anodized aluminum plate is much harder. The oxide layer created during anodizing is almost as hard as diamond. Raw aluminum is soft. If you scratch raw aluminum, the mark stays there. If you try to scratch a hard-anodized plate, it is very difficult. This is vital for parts that move or rub against other parts.

Raw aluminum looks like metal, but it can look dull or inconsistent. An anodized aluminum plate has a uniform, metallic look. We can control the gloss and color. It looks premium. Raw aluminum often shows mill finish lines from the roller, which many end-users find unattractive.

This is a tricky point. Aluminum conducts electricity very well. However, the oxide layer on an anodized aluminum plate acts as an insulator. It does not conduct electricity. If your part needs to be grounded, we mask certain areas before anodizing. Raw aluminum conducts electricity everywhere.

Here is a comparison to help you choose:

| Caratteristica | Raw Aluminum Sheet | Anodized Aluminum Plate |

| Surface Hardness | Low (Soft) | High (Ceramic-like) |

| Resistenza alla corrosione | Moderato | Excellent |

| Color Options | Silver only | Unlimited colors |

| Electrical Conductivity | Alto | Low (Insulator) |

| Costo | Lower | Higher (adds value) |

In my experience dealing with buyers from the US and Europe, switching to an anodized aluminum plate reduces customer complaints regarding scratches and surface defects. It costs a bit more upfront, but it saves money on returns and warranty claims later.

Corrosion is a purchasing manager’s nightmare, especially for outdoor equipment. You need to know if this material survives rain, salt, and sun.

An anodized aluminum plate does not rust because it contains no iron. It is highly resistant to corrosion, even in outdoor environments, as the anodic layer creates a barrier that prevents oxidation from air and moisture.

Technically, “rust” only happens to iron and steel. However, aluminum can corrode. It turns into a white powder if exposed to salt and moisture for too long. But an anodized aluminum plate is different. It is built to fight this.

Think of the anodized layer as a shield. It is part of the metal, not just a skin. It stops oxygen from reaching the aluminum underneath. I have seen anodized parts used on boats and buildings near the ocean that look new after ten years. This is because we control the thickness of that layer.

For outdoor use, the thickness of the anodizing is key. We measure this in microns.

While an anodized aluminum plate is tough, it has a weakness. High alkaline or high acid chemicals can damage it. For example, strong industrial cleaners or wet mortar from construction can stain the surface. I always advise my clients to protect the surface during installation.

One reason my clients love this material is low maintenance. You usually just need water and mild soap to clean it. You do not need special oils or paints to keep it safe from corrosion.

I recall a project for a client in Canada. They needed panels for outdoor kiosks. They worried about snow and road salt. We supplied a 25-micron anodized aluminum plate. Three years later, they told me the panels still looked perfect. This proves that with the right specs, corrosion is not an issue.

You need versatile materials for your diverse product lines. Let’s see where this metal performs best and where it creates the most value.

Typical uses for anodized aluminum plates include architectural facades, consumer electronics casings, automotive parts, and industrial machinery. Its durability and aesthetic appeal make it ideal for both structural components and high-end design elements.

Because we can customize the anodized aluminum plate, it fits into almost every industry. At ALUT, we ship these plates for very different uses.

Look at your laptop or smartphone. If it has a metal body, it is likely an anodized aluminum plate. Electronics companies love it because it dissipates heat well (better than plastic) and looks expensive. It also protects the delicate internal parts from static electricity due to its insulating nature.

In construction, architects use anodized aluminum plate for building exteriors, window frames, and roofing. It reflects sunlight, which helps cool buildings. Plus, it does not chip or peel like paint. I have sent containers of these plates to Europe for curtain wall projects. The builders prefer it because it is lightweight, making it easier to install than steel or stone.

Cars need to be light to save fuel. Anodized aluminum plate is perfect here. It is used for trim, dashboards, and even structural parts. In the marine industry, it is used for boat fittings because of the salt resistance we discussed earlier.

This is a huge market for us. Factory machines need parts that do not wear out. We make base plates, robot arms, and jigs using hard-anodized aluminum plate. The hard coating ensures the machine parts stay accurate over time.

Here is a quick reference guide for applications based on the alloy we recommend:

| Industria | Recommended Alloy | Why? |

| Architecture | 5005 or 6061 | Good strength and excellent anodizing finish quality. |

| Elettronica | 5052 | Formable and looks great after anodizing. |

| Machinery | 6061 or 7075 | High strength. 7075 is as strong as some steels. |

| Marine | 5083 | Best corrosion resistance for saltwater. |

When you choose an anodized aluminum plate, you are choosing a material that works hard in almost any setting. Whether you are making LED lights or heavy equipment, there is a specification that fits your needs.

An anodized aluminum plate offers unmatched durability and style. It solves corrosion and wear issues effectively.