Indirizzo

304 Nord Cardinale

St. Dorchester Center, MA 02124

Orario di lavoro

Da lunedì a venerdì: dalle 7.00 alle 19.00

Fine settimana: 10.00 - 17.00

Indirizzo

304 Nord Cardinale

St. Dorchester Center, MA 02124

Orario di lavoro

Da lunedì a venerdì: dalle 7.00 alle 19.00

Fine settimana: 10.00 - 17.00

I often wonder, when facing material choices, if I’m truly making the best decision. Let’s find out if anodized aluminum angle can offer the strong solution we need.

Anodized aluminum angle is made through an electrolytic passivation process. This process increases the thickness of the natural oxide layer on the metal’s surface. This makes the aluminum more durable and corrosion-resistant. It also gives it a better aesthetic finish.

Choosing the right material can feel overwhelming, but understanding the basics of anodized aluminum angle will help you make a confident choice for your projects. Let’s look closer.

Have you ever thought about how a simple piece of metal becomes so resilient and visually appealing? I certainly have, especially when looking for reliable components.

Anodized aluminum angle is made by placing aluminum in an acid electrolyte bath. Electric current then passes through the bath. This causes an oxide layer to grow on the aluminum’s surface. This layer is much harder and thicker than the natural oxide layer.

The manufacturing of anodized aluminum angle involves a careful chemical process. First, aluminum angle pieces are thoroughly cleaned. This removes any dirt, grease, or natural oxides. Cleaning is important for the anodizing process to work well. After cleaning, the aluminum parts go into a tank. This tank holds an electrolyte solution. Sulfuric acid is a common electrolyte used for this. Other acids can also be used depending on the desired outcome.

Next, an electric current runs through the electrolyte. The aluminum acts as the anode, which is the positive electrode. A cathode, the negative electrode, is also in the tank. When the current flows, oxygen ions from the electrolyte combine with the aluminum atoms. This forms aluminum oxide on the surface of the aluminum. This new oxide layer is porous at first. The pores are like tiny holes.

There are different types of anodizing. Type II, or sulfuric acid anodizing, creates a thinner, clear layer. Type III, or hard coat anodizing, creates a much thicker and denser layer. This layer is very resistant to wear. After the anodizing step, the parts often go through a sealing process. Sealing closes the pores in the oxide layer. This makes the layer even more resistant to corrosion and staining. Without sealing, the porous layer would absorb stains easily.

Finally, if color is desired, the parts can be dyed before sealing. The dye enters the pores. Then, sealing locks the color in. This gives anodized aluminum angle its wide range of color options. The entire process requires careful control of temperature, current density, and time. This ensures a consistent and high-quality finish.

| Step | Descrizione | Scopo |

| Cleaning | Removal of oils, dirt, and natural oxides | Prepares surface for uniform anodizing |

| Rinsing | Washing off cleaning solutions | Prevents contamination of electrolyte bath |

| Etching | Chemical immersion to remove surface imperfections | Creates a uniform, matte surface |

| Anodizzazione | Electrolytic process in acid bath | Grows a protective oxide layer |

| Rinsing | Washing off electrolyte solution | Prevents contamination of sealing bath |

| Dyeing (Optional) | Immersion in organic or inorganic dye | Adds color to the oxide layer |

| Sealing | Hydration of aluminum oxide pores | Enhances corrosion resistance and prevents staining |

Have you ever wondered why anodized aluminum angle shows up in so many different products around us? I often see it and think about its versatility.

Anodized aluminum angle is used in many industries because of its strength, light weight, and good looks. It is common in architectural trim, window frames, and furniture. It is also used in marine parts, electronics, and various custom fabrications.

Anodized aluminum angle is a very versatile material. Its unique properties make it suitable for many applications. In architecture, it is a favorite for building exteriors and interiors. You can see it as decorative trim on walls, ceilings, and floors. It is also used for window frames and door frames. Its resistance to weather and wear means it lasts a long time, even in busy areas. The different colors and finishes available also allow designers more freedom.

For furniture makers, anodized aluminum angle provides both strength and a modern look. It is often used for chair frames, table legs, and shelving units. It can be bent and cut into many shapes. This makes it good for custom designs. Its light weight also makes furniture easier to move.

In electronics, anodized aluminum angle helps protect sensitive components. It can be used for enclosures or heat sinks. The anodized layer acts as an electrical insulator. This is important for safety and performance. It also helps dissipate heat from electronic devices. This keeps them from overheating.

The marine industry also uses anodized aluminum angle. Boats and docks often use it for railings, supports, and fixtures. Saltwater can quickly damage many metals. However, anodized aluminum has excellent corrosion resistance. This makes it a good choice for marine environments. It stands up well to both fresh and saltwater.

Beyond these common uses, anodized aluminum angle is also found in custom machinery, retail displays, and signs. Its ability to be easily customized in terms of size, shape, and finish makes it a go-to material for many different engineering and design needs. It offers a strong balance of function and appearance.

| Industria | Common Applications | Key Benefits |

| Architecture | Window frames, door frames, decorative trim, curtain walls | Durability, aesthetic appeal, weather resistance |

| Furniture | Chair frames, table legs, shelving, cabinet components | Light weight, strength, modern look, corrosion resistance |

| Elettronica | Enclosures, heat sinks, mounting brackets | Electrical insulation, heat dissipation, protection |

| Marine | Railings, boat fixtures, dock components | Superior corrosion resistance, light weight |

| Automotive | Interior trim, structural components, aftermarket parts | Light weight, strength, aesthetic customization |

Have you ever considered how different finishes can completely change the look and feel of a product? I often find myself thinking about the impact of surface treatment.

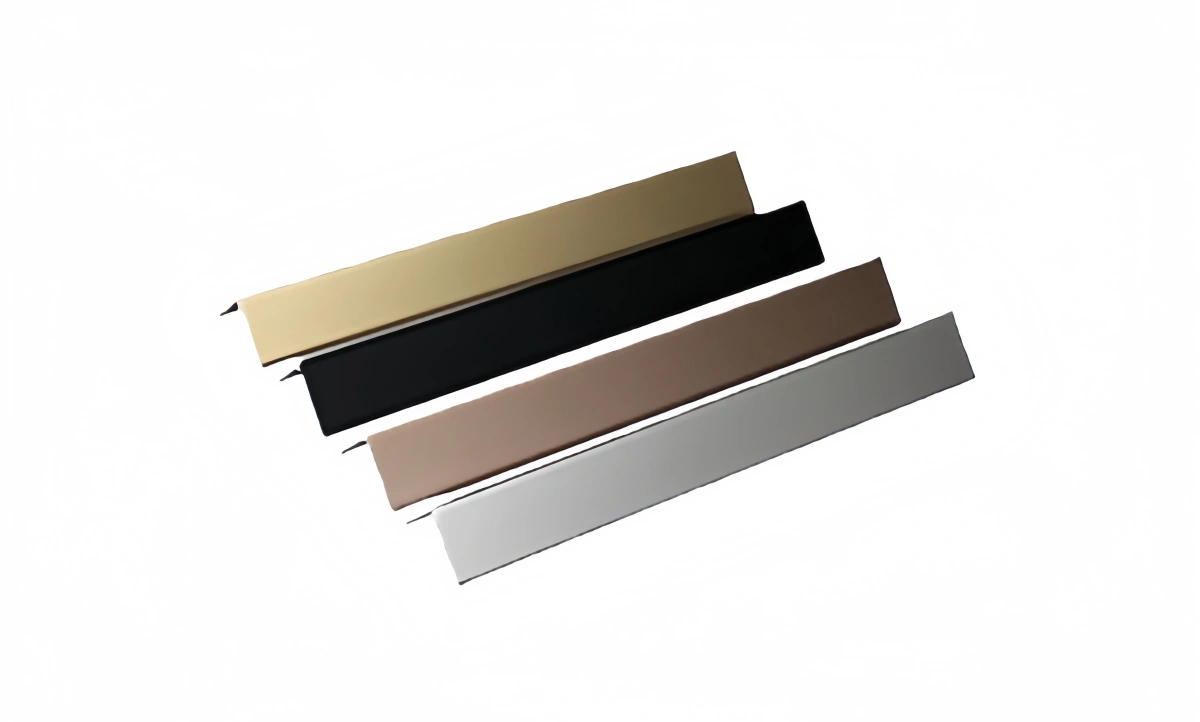

Anodized aluminum angle offers a wide array of finishes. These finishes include clear, black, bronze, and custom colors. These options allow for specific aesthetic and functional needs. The finish can range from matte to glossy, providing great design flexibility.

The range of finishes available for anodized aluminum angle is a major reason for its popularity. The most basic finish is clear anodize. This finish enhances the natural metallic look of aluminum. It adds a clear, protective layer. It keeps the natural silver-gray color of the aluminum. Many people choose it for a clean, modern appearance.

Beyond clear, you can find anodized aluminum angle in various colors. Black anodize is very popular. It gives a sleek, high-end look. Bronze tones, from light to dark, are also common. These are often used in architectural projects. They can match other building materials. Custom colors are also possible. This depends on the dye used during the anodizing process. Manufacturers can match specific color requirements for branding or design schemes.

The texture of the finish can also vary. Some finishes are bright and reflective, like a polished metal. Others are dull or matte. A matte finish helps to reduce glare. It can also hide minor surface imperfections better. The choice of finish depends on where the aluminum angle will be used. For example, a high-traffic area might need a finish that hides scratches well. An outdoor application might need a finish that resists fading from sunlight.

The thickness of the anodized layer also affects the finish. Thicker layers, like those from hard coat anodizing, offer more durability. They might have a slightly different appearance than thinner layers. Understanding these finish options helps in choosing the perfect anodized aluminum angle for any project. It ensures both function and desired look are met.

| Finish Type | Appearance | Common Applications | Characteristics |

| Clear Anodize | Translucent, silvery-gray metallic | Architectural trim, general purpose, industrial | Enhances natural aluminum look, good protection |

| Black Anodize | Opaque, deep black | Electronic enclosures, automotive, decorative | Sleek, modern, high aesthetic appeal |

| Bronze Anodize | Various shades of brown/bronze | Architectural facades, doors, windows | Classic look, good UV resistance, matches other materials |

| Gold Anodize | Bright or satin gold tone | Decorative items, luxury goods, signage | Luxurious appearance, highly decorative |

| Custom Colors | Wide range of colors (blue, red, green, etc.) | Specialty products, branding, artistic designs | Unique aesthetics, broad design flexibility |

Have you ever questioned if a material can truly stand up to the harshness of outdoor environments? I always look for materials that can withstand the test of time and weather.

Yes, anodized aluminum angle is highly suitable for outdoor use. Its anodized layer provides excellent resistance to corrosion, UV radiation, and general weathering. This makes it a durable choice for outdoor architectural, marine, and other exposed applications.

Anodized aluminum angle is indeed a great choice for outdoor use. The anodizing process creates a protective oxide layer on the aluminum surface. This layer is much harder and more stable than the natural oxide layer that forms on raw aluminum. This enhanced layer is key to its outdoor performance.

One of the main benefits is its corrosion resistance. The anodized layer acts as a barrier. It protects the aluminum from moisture, salt spray, and pollution. This means it will not rust like steel. It also resists common forms of corrosion that can affect raw aluminum. This is especially important in coastal areas or industrial environments where corrosive agents are present.

Another important factor for outdoor materials is UV resistance. Sunlight, especially its ultraviolet rays, can degrade many materials over time. It can cause fading or material breakdown. The anodized layer on aluminum helps to resist UV degradation. This means the color and integrity of the aluminum angle will last longer, even under direct sunlight.

The hard surface of anodized aluminum also provides good scratch and abrasion resistance. This is useful for outdoor applications where parts might be exposed to physical contact or harsh conditions. For example, railings or external trim need to withstand impacts and general wear. While no material is entirely indestructible, anodized aluminum offers a strong defense against common outdoor challenges. This makes it a reliable and long-lasting choice for many exterior projects.

| Fattore | Anodized Aluminum Performance | Importance for Outdoor Use |

| Resistenza alla corrosione | Excellent; barrier against moisture, salt, pollutants | Prevents rust and material breakdown in harsh environments |

| UV Resistance | Good; resists fading and degradation from sunlight | Maintains aesthetic and structural integrity over time |

| Wear Resistance | High; hard oxide layer resists scratches and abrasion | Durable in high-traffic or exposed applications |

| Temperature Stability | Good; performs well in various temperatures | Suitable for diverse climates without warping or cracking |

| Chemical Resistance | Good; withstands mild acids and alkalis | Resists damage from environmental pollutants and cleaning agents |

Anodized aluminum angle offers a superb combination of durability, aesthetic flexibility, and outdoor suitability. Its manufacturing process gives it amazing resistance, making it a powerful choice for many uses.