Indirizzo

304 Nord Cardinale

St. Dorchester Center, MA 02124

Orario di lavoro

Da lunedì a venerdì: dalle 7.00 alle 19.00

Fine settimana: 10.00 - 17.00

Indirizzo

304 Nord Cardinale

St. Dorchester Center, MA 02124

Orario di lavoro

Da lunedì a venerdì: dalle 7.00 alle 19.00

Fine settimana: 10.00 - 17.00

Are you struggling to find the right materials for your project? I know that choosing the wrong component can lead to costly failures, production delays, and budget overruns.

From my professional experience, aluminum extrusion products are custom-shaped components created by forcing heated aluminum alloy through a die. I believe they are one of the most versatile manufacturing solutions available today, used in everything from window frames to complex parts for electric vehicles.

This versatility is their greatest strength. But to use them effectively, you need to understand what they are, why they are beneficial, and how they are made. Let’s explore the details so you can source them with confidence.

I know you see them everywhere, but do you recognize their full potential? Limiting your view of aluminum extrusions to just window frames means you’re missing huge opportunities for innovation.

In my work, I see a huge range of examples. Common aluminum extrusion products include T-slot profiles for industrial frames, heat sinks for electronics, architectural window and door frames, and structural components for cars and solar panel mounts. They are truly everywhere.

The applications for aluminum extrusion products are incredibly diverse. They are found in almost every major industry because the process allows for the creation of very complex cross-sections that are strong and lightweight.

For a purchasing manager, understanding this range can open up new possibilities for product design and cost savings. I’ve often consulted with clients who were using expensive, multi-part steel assemblies. We replaced them with a single, custom aluminum extrusion product that was cheaper, lighter, and easier to assemble.

This is the most visible market for aluminum extrusion products. You see them in window frames, door frames, curtain wall systems, and railings.

The material’s natural corrosion resistance and ability to be anodized in different colors make it perfect for exterior use. Custom profiles are also created for things like canopy systems, skylight frames, and interior partition walls.

The push for lighter, more fuel-efficient vehicles has made aluminum extrusion products essential. They are used for structural components like battery enclosures for electric vehicles, crash management systems, roof rails, and chassis parts.

In public transport, you find them in the frames of buses, trains, and subway cars. Their high strength-to-weight ratio is the key benefit here.

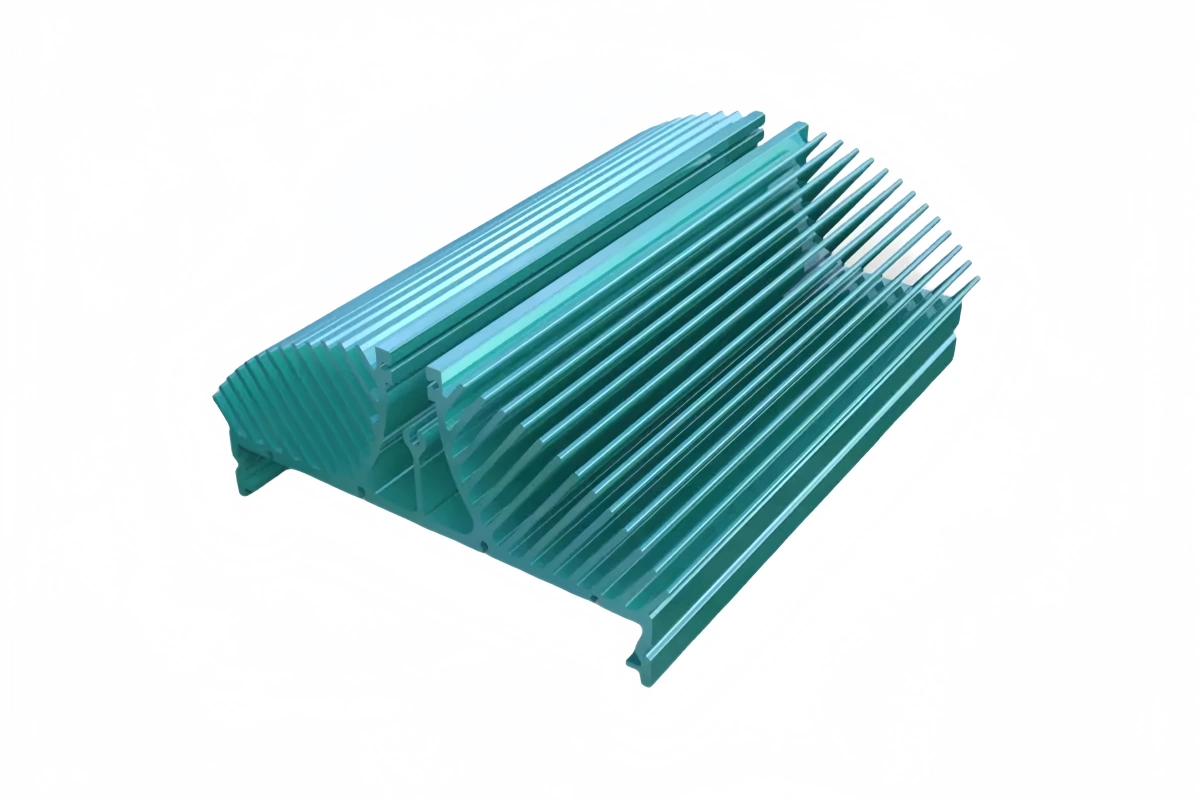

Heat management is a major challenge in electronics. Aluminum is an excellent thermal conductor, so aluminum extrusion products are the standard for creating heat sinks.

The extrusion process can create fins with a very high surface area to dissipate heat effectively from CPUs, LEDs, and power amplifiers. They are also used to create sleek, durable enclosures for laptops, servers, and other electronic devices.

| Application Category | Common Examples of Aluminum Extrusion Products | Vantaggi principali |

| Architectural | Window frames, curtain walls, door frames | Corrosion resistance, aesthetics |

| Industrial | T-slot profiles, machine guards, conveyor rails | Modularity, ease of assembly |

| Elettronica | Heat sinks, device enclosures, server racks | Thermal conductivity, precision |

| Automotive | Battery trays, roof rails, structural parts | High strength-to-weight ratio |

I know you’re constantly balancing cost, weight, and performance. Steel is strong but heavy and rusts. Plastic is light but often not strong enough for structural applications. It’s a common dilemma.

From my direct experience, the main benefits are a fantastic strength-to-weight ratio, excellent natural corrosion resistance, and incredible design flexibility. I believe these three advantages make aluminum extrusion products a superior choice for a huge number of applications.

When you choose a material for your project, you’re making a strategic decision that impacts cost, performance, and longevity. Aluminum extrusion products offer a unique combination of benefits that often make them a more intelligent choice than traditional materials.

For a purchasing manager, these benefits translate directly to a better return on investment and a more reliable supply chain. I have guided countless clients through this decision process, and the advantages of aluminum are consistently clear.

This is perhaps the most well-known benefit. Aluminum is about one-third the weight of steel, which makes aluminum extrusion products much easier and cheaper to transport and handle.

But this light weight does not mean low strength. Specific aluminum alloys can be heat-treated to achieve impressive tensile strengths. This makes them suitable for many structural applications where steel was once the only option, a critical advantage in automotive and aerospace.

Aluminum naturally generates a protective oxide layer on its surface. This layer is extremely resistant to corrosion, which means aluminum extrusion products will not rust like steel. This makes them ideal for applications in harsh or wet environments.

For even greater protection, the surface can be anodized or powder-coated. I remember a client who switched from steel to aluminum for outdoor enclosures. Their maintenance costs dropped to almost zero because they no longer had to deal with rust.

The extrusion process is what makes these products so special. It allows for the creation of very intricate cross-sectional shapes.

Features like screw ports, interlocking joints, and T-slots can be integrated directly into the profile design. This eliminates the need for additional components and secondary machining, reducing assembly time and overall project costs.

| Property | Aluminum | Steel | Plastic (ABS) |

| Density (g/cm³) | ~2.7 | ~7.85 | ~1.06 |

| Resistenza alla corrosione | Excellent | Poor (unless treated) | Excellent |

| Design Complexity | Very High | Low (fabrication needed) | High (injection molding) |

| Riciclabilità | Excellent / High Value | Good | Poor / Low Value |

Have you ever wondered how a simple block of aluminum becomes a complex, finished part? I know that not understanding the manufacturing process can make it difficult to design custom profiles effectively.

As a factory owner, I oversee this process daily. First, a cylindrical aluminum billet is heated to around 450-500°C. Then, a powerful hydraulic press forces the softened metal through a steel die, which has a shaped opening. The metal emerges from the die as a long, continuous profile.

The manufacturing of aluminum extrusion products combines heat, immense pressure, and precision engineering. Understanding these steps is important for a purchasing manager because it helps you appreciate the factors that affect quality, lead time, and cost. It’s a well-controlled industrial process that we have perfected over many years. I’ve walked hundreds of clients through our factory floor to show them exactly how their custom parts are born.

Everything starts with the die. The die is a round, thick disk of H13 tool steel with an opening machined into it. This opening is the exact cross-section of the final profile. At the same time, a solid log of a specific aluminum alloy, called a billet, is heated in an oven until it is malleable but not molten.

The heated billet is placed in the extrusion press. A hydraulic ram applies immense pressure, pushing the soft aluminum through the die opening. As it emerges, it is a fully formed profile. The profile is guided onto a runout table and immediately cooled with water or fans. This quenching is a critical step that locks in the material’s properties.

After cooling, the long profile can have minor twisting. To correct this, it is mechanically stretched, which straightens the profile and hardens it. The long profiles are then moved to a finishing saw and cut to the specified lengths. For many alloys, the aluminum extrusion products are moved to an aging oven for a final heat treatment. This process, called artificial aging, brings them to their optimal temper and strength.

I know from experience that choosing the wrong alloy is a costly and dangerous mistake. A part that is too soft for its application will fail, causing production stops and potential safety issues.

In my factory, we most commonly work with two major alloy families: the 6000 series and the 7000 series. For over 90% of applications, I recommend either 6063 for its excellent finish or 6061 for its superior structural strength. The choice depends entirely on the part’s final use.

The alloy you choose for your aluminum extrusion products is one of the most important decisions in your design. It determines key properties like strength, machinability, corrosion resistance, and surface finish.

While there are hundreds of alloys, a few have become industry standards. As a supplier, my team’s first job is to help you select the alloy that provides the performance you need without over-engineering and adding unnecessary cost.

This is one of the most popular extrusion alloys in the world, alloyed with magnesium and silicon. 6063 is known for its excellent surface finish and high corrosion resistance. This makes it the top choice for architectural applications and decorative trim. If your product needs to look good and withstand the elements, 6063 is almost always my first recommendation.

When strength matters more than a perfect finish, 6061 is the answer. It contains more magnesium and silicon, plus copper. This gives 6061 significantly higher tensile strength, making it a workhorse for structural applications. I see it used for machine frames, automotive parts, and any part that must bear a significant load.

While 6063 and 6061 cover most applications, other alloys are used for specific needs. 6005A offers a good compromise of strength and extrudability. For the highest strength requirements, alloys from the 7000 series (like 7075) are used. These are common in aerospace, but they are more expensive.

| Lega | Key Characteristic | Typical Application |

| 6063 | Excellent surface finish | Window frames, trim, enclosures |

| 6061 | High structural strength | Machine frames, automotive parts |

| 6005A | Good balance of strength/extrudability | Rail car components, tubing |

| 7075 | Extremely high strength | Aerospace, high-end sporting goods |

Understanding the examples, benefits, manufacturing, and alloys of aluminum extrusion products is key. It empowers you to make smarter, more cost-effective sourcing decisions for your company’s projects.