Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

As a buyer, I know how frustrating it can be to find the right materials. I understand the pain of dealing with poor quality and missed deadlines. Polished aluminum tubing might just be the solution you need.

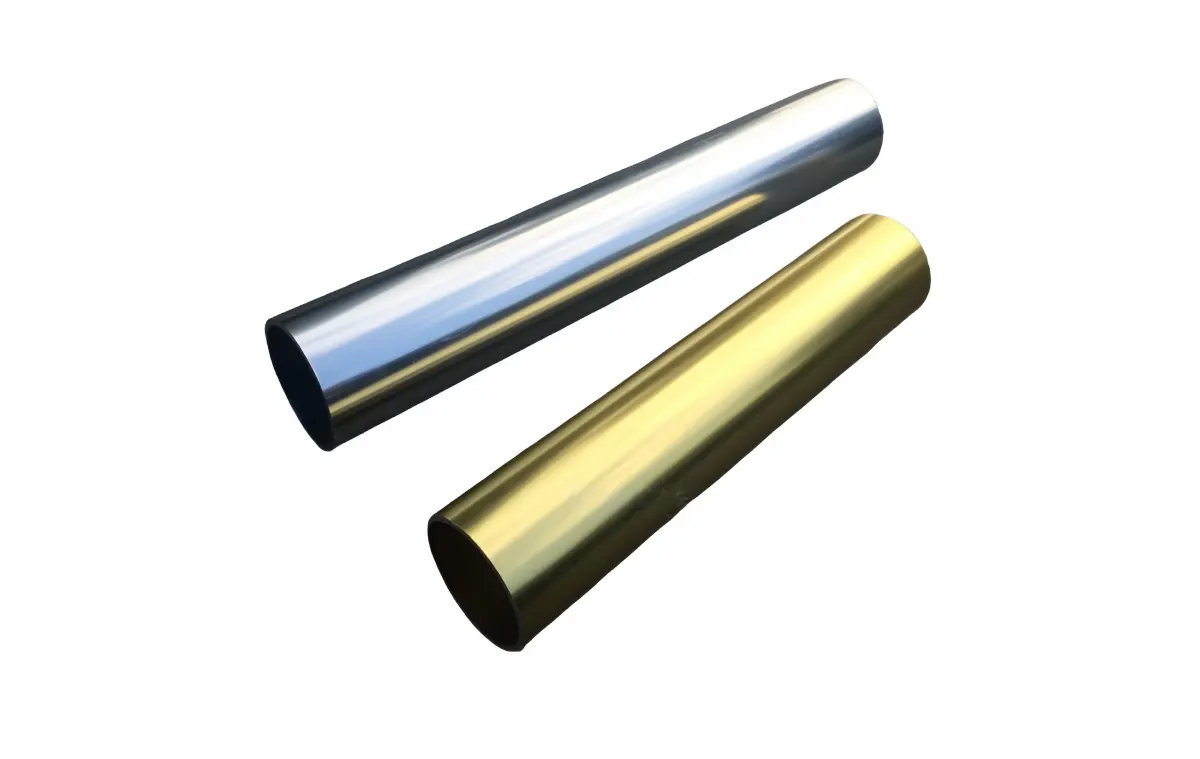

Polished aluminum tubing offers excellent corrosion resistance, a beautiful finish, and a high strength-to-weight ratio. I often recommend it for projects where aesthetics and performance are key. It’s a versatile material that can truly elevate your products.

Let’s dive deeper into why this material could be the perfect fit for your next project. Keep reading to see how polished aluminum tubing can make a difference.

I often get asked about material choices. I’ve seen many projects struggle because of the wrong selection. But when it comes to polished aluminum tubing, I can tell you it stands out.

Polished aluminum tubing is a preferred choice due to its light weight, durability, and attractive appearance. I have seen it enhance the look and longevity of many products, making it a reliable option for various applications. It simply offers a great balance of features.

Many factors make polished aluminum tubing an excellent choice for a variety of industrial and aesthetic uses. First, its light weight is a major benefit. Aluminum is naturally much lighter than steel or copper. This makes polished aluminum tubing easier to handle, transport, and install. For products like LED lights or industrial machines, reducing overall weight can improve efficiency and lower shipping costs. This is a critical advantage for many of our clients.

Second, the durability of polished aluminum tubing is impressive. Aluminum forms a natural oxide layer when exposed to air. This layer protects the metal from rust and corrosion. This means polished aluminum tubing lasts longer, even in harsh environments. My experience shows that this corrosion resistance is very important for products used outdoors or in humid conditions. It means less maintenance and a longer product lifespan.

Third, the aesthetic appeal of polished aluminum tubing is unmatched. The polishing process gives it a bright, reflective surface. This makes it look sleek and modern. For consumer products or visible parts of machinery, the appearance really matters. I have seen how a high-quality finish can make a product more attractive to buyers. This can increase its market value.

Finally, aluminum is very easy to work with. It can be extruded into various shapes and sizes, including tubes. This allows for great design flexibility. You can get polished aluminum tubing that perfectly fits your project’s needs. The ease of fabrication also means lower production costs. This is something our clients always appreciate.

| Benefit | Description |

| Light Weight | Reduces overall product weight and shipping costs. |

| Corrosion Resistance | Protects against rust and extends product life. |

| Aesthetic Appeal | Provides a modern, high-end look. |

| Workability | Easy to shape and customize for specific needs. |

I remember visiting factories where they make metal parts. The process for polished aluminum tubing is truly fascinating. I always learn something new when I see it in action.

Polished aluminum tubing is typically manufactured through extrusion, followed by a series of polishing steps to achieve its desired shine. I have seen firsthand how precise these processes are to ensure a high-quality finish. It involves both careful shaping and surface treatment.

The manufacturing of polished aluminum tubing involves several key steps. It starts with the extrusion process. First, aluminum billets, which are solid pieces of aluminum, are heated to a high temperature. Then, these softened billets are pushed through a die. A die is a special tool with a specific opening. As the aluminum passes through the die, it takes on the shape of a tube. This is like squeezing toothpaste out of a tube. The shape of the die determines the tube’s cross-section. This step is crucial for getting the correct dimensions for the polished aluminum tubing.

After extrusion, the aluminum tubes are usually cut to the desired lengths. At this stage, the surface of the tube is still rough. It does not have the shiny, smooth finish yet. This is where the polishing process begins. Polishing is done in multiple stages.

This detailed process ensures that the polished aluminum tubing not only has the correct shape but also a flawless and attractive surface. Each step is important for the final product’s quality.

When I think about where polished aluminum tubing is used, I see it everywhere. From daily items to complex machines, its versatility always impresses me.

Polished aluminum tubing is widely used in various industries, including automotive, furniture, architectural design, and consumer goods. I have found its aesthetic appeal and structural integrity make it ideal for both functional and decorative applications. It’s a truly adaptable material.

Polished aluminum tubing finds its way into many different applications because of its unique properties. Its combination of light weight, strength, and attractive finish makes it suitable for a wide range of products.

One common area is the automotive industry. Polished aluminum tubing is used for custom exhaust systems, roll cages, and decorative trim. Its light weight helps reduce the overall vehicle weight. This can improve fuel efficiency. Its shiny surface also adds to the car’s appearance. I have seen how it can make a car look more sporty and high-end.

Another significant use is in furniture design. Polished aluminum tubing is popular for modern and contemporary furniture. It is used in chairs, tables, and shelving units. The sleek look fits well with minimalist designs. Also, its strength ensures the furniture is durable. I have personally seen furniture pieces made with this tubing that last for many years, looking as good as new.

In architectural design, polished aluminum tubing is used for railings, decorative elements, and light fixtures. Its corrosion resistance is very important here. It can withstand outdoor conditions without losing its shine or integrity. Architects like it because it offers both strength and a clean, modern aesthetic. It helps create impressive structures.

| Industry | Common Applications |

| Automotive | Exhaust systems, roll cages, decorative trim |

| Furniture | Chairs, tables, shelving units |

| Architecture | Railings, decorative elements, light fixtures |

| Consumer Goods | Sports equipment, display stands, appliance components |

Polished aluminum tubing is also common in consumer goods. This includes items like sports equipment, bicycle frames, and even parts of high-end appliances. Its light weight is beneficial for anything that needs to be portable. Its strength makes sure the products are safe and long-lasting. I always tell my clients that using polished aluminum tubing can make their products stand out in a crowded market. It truly offers both beauty and function.

When I help clients choose materials, finish is often a big discussion. The right finish can completely change a product’s look and feel. Polished aluminum tubing offers some excellent options.

Beyond a basic polish, polished aluminum tubing can come with various finishes, including mirror polish, brushed, and anodized options. I always recommend considering the specific aesthetic and protective needs of your project when choosing a finish. Each finish offers unique advantages.

Polished aluminum tubing can undergo several finishing processes to achieve different appearances and levels of protection. The choice of finish depends on the application, desired aesthetic, and environmental factors.

Each of these finishes not only changes the look of the polished aluminum tubing but also affects its performance. For example, anodizing significantly improves scratch resistance. A mirror polish, while beautiful, might require more careful handling to maintain its flawless look. Choosing the right finish is about balancing beauty with practical needs. It is important to think about where the polished aluminum tubing will be used and how it will be maintained.

Polished aluminum tubing truly is an amazing material. It offers strength, light weight, and a great look. I believe it can solve many of your project challenges and make your products shine.