Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

I often hear questions about how to protect aluminum while keeping its shine. It’s a common challenge we face in manufacturing.

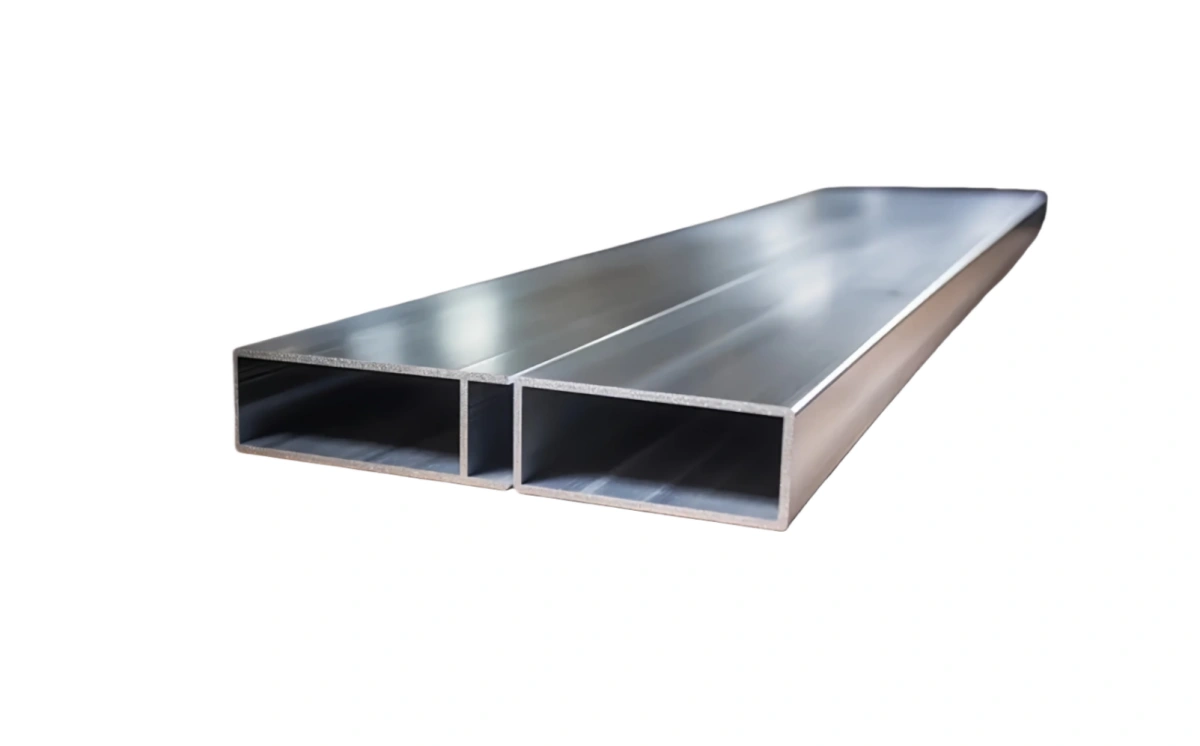

Clear anodizing polished aluminum is a fantastic process that uses an electrochemical method to grow a protective oxide layer on the aluminum’s surface. This layer significantly increases corrosion resistance and hardness, all while preserving the metal’s attractive, polished look.

Let’s explore further how this powerful combination works and why it might be the perfect solution you’ve been searching for.

I’ve seen many clients struggle with aluminum finishes. They want durability but don’t want to lose that beautiful luster.

Clear anodizing polished aluminum involves creating a transparent, durable, and protective oxide coating on aluminum through an electrolytic process. This method maintains the aluminum’s original polished appearance while greatly improving its surface properties.

Clear anodizing polished aluminum is a two-step process. First, we polish the aluminum. This makes the surface smooth and shiny. Polishing removes small scratches and marks. It prepares the aluminum for the next step. Then, we do the clear anodizing. Anodizing is an electrochemical process. We put the aluminum into an acidic solution. We pass an electric current through it. This grows a clear, hard oxide layer on the aluminum’s surface. This layer is part of the aluminum itself. It is not just a coating that sits on top. Because it is clear, the polished look of the aluminum still shows through. The oxide layer makes the aluminum much more resistant to scratches. It also protects against corrosion. This means the aluminum will last longer. It will look good for a longer time. Many industries use this process.

The protective layer formed during anodizing is aluminum oxide. This is a very hard material. It is harder than the base aluminum. This extra hardness helps prevent scratches. It also makes the surface less prone to wear. Think of it like a shield. This shield is clear, so you can still see the shiny aluminum underneath. The anodized layer also acts as a barrier. It stops chemicals and moisture from reaching the aluminum surface. This prevents corrosion. Without this layer, polished aluminum can tarnish or corrode over time. The clear anodized layer keeps it looking new.

| Feature | Description |

| Enhanced Durability | The surface becomes much harder, resisting scratches and abrasion. |

| Corrosion Resistance | Forms a barrier against oxidation, moisture, and chemical attack. |

| Aesthetic Appeal | Preserves the bright, reflective finish of polished aluminum. |

| Electrical Insulation | The oxide layer is non-conductive, offering some electrical insulation. |

| Easy Maintenance | The smooth, hard surface is easier to clean and maintain. |

Many of my manufacturing partners wonder about the steps involved. It’s crucial to understand for quality control.

The process for clear anodizing polished aluminum typically involves cleaning, etching, desmutting, anodizing in an acid bath, and then sealing the porous oxide layer. Each step is carefully controlled to create a uniform, durable, and transparent finish.

The clear anodizing polished aluminum starts with thorough cleaning. We must remove all dirt, oil, and grease from the aluminum surface. This is important for the anodizing layer to stick well. We use alkaline cleaners for this. After cleaning, the aluminum goes through an etching step. Etching uses a mild chemical solution. This step helps create a uniform surface. It also removes any small imperfections. Next is desmutting. This step removes any residues left from the etching process. These residues can be dark films or “smut.” They must be removed for a clear finish.

After the clear anodizing polished aluminum are rinsed. The final step is sealing. Sealing closes the pores in the oxide layer. This makes the layer even more protective. Without sealing, the porous layer would absorb stains. It would also be less resistant to corrosion. We can use different sealing methods. Hot water sealing is common. It uses hot deionized water. This causes the aluminum oxide to hydrate and swell, closing the pores. Nickel acetate sealing is another option. It offers very good corrosion resistance. The sealing step is critical. It determines the final performance of the clear anodized aluminum. A well-sealed part will resist corrosion and wear much better.

During the clear anodizing polished aluminum, many factors can affect the final quality. Temperature of the bath, concentration of chemicals, and electrical current density are all important. If the cleaning is not perfect, the anodized layer can be uneven. If the desmutting is not done well, the finish might not be clear. We use strict quality control checks at each stage. This ensures a consistent and high-quality finish. We check the thickness of the anodized layer. We also test for corrosion resistance. Visual inspection is also key. We look for any defects or inconsistencies in the clear finish. This careful control ensures that the final product meets high standards.

| Anodizing Step | Purpose | Key Control Points |

| Cleaning | Remove contaminants for proper layer adhesion. | Chemical concentration, temperature, contact time. |

| Etching | Create uniform surface, remove minor flaws. | Chemical concentration, temperature, time. |

| Desmutting | Eliminate residues from etching for clear finish. | Chemical composition, contact time. |

| Anodizing | Grow the protective aluminum oxide layer. | Voltage, current density, bath temperature, time. |

| Sealing | Close pores to enhance corrosion resistance and stain protection. | Sealing temperature, time, chemical purity. |

This is a frequent concern for buyers looking for both aesthetics and protection. I always tell them, yes!

Yes,clear anodizing polished aluminum can be clear anodized effectively, and this process is highly valued for combining the aesthetic appeal of a polished surface with the enhanced durability and corrosion resistance of an anodized finish. The key is proper surface preparation.

Polished aluminum can be clear anodized very well. Many people choose this finish because it looks good and is very durable. The bright, shiny surface of polished aluminum is very attractive. clear anodizing polished aluminum adds a hard, transparent layer over this polished surface. This layer protects the aluminum. It stops it from getting scratches. It also stops it from corroding. The success of clear anodizing on polished aluminum depends a lot on how well we prepare the surface. If the polishing is not done right, the anodized layer will not look as good. Any marks or imperfections on the polished surface will show through the clear anodized layer. So, a good polishing job is the first step to a good clear anodized finish. We must make sure the aluminum is very clean before anodizing. Any oil or dirt will cause problems. It can lead to an uneven finish. It can also cause the anodized layer not to stick properly.

While effective, there are some challenges. The polishing step itself can be tricky. It needs skilled workers and the right equipment. Over-polishing or under-polishing can cause issues. Also, achieving a completely uniform polished surface across large or complex parts is hard. Any inconsistencies in the polish will be visible through the clear anodized layer. Another challenge is avoiding contamination during the process. Even small dust particles can cause defects. So, we use clean rooms and strict protocols. This helps ensure a perfect finish. Despite these challenges, the benefits often outweigh the difficulties. The combination of beauty and protection is very valuable.

Many products need both a beautiful look and strong protection.

My clients often ask about practical applications. They want to see how it can benefit their products.

clear anodizing polished aluminum is typically used in applications where both high aesthetic appeal and enhanced durability are required, such as architectural components, consumer electronics, automotive trim, and high-end consumer goods, due to its protective yet transparent finish.

clear anodizing polished aluminum is used in many different places. These places need parts that look good and are strong. One main area is in buildings. Architectural components like window frames, door handles, and decorative panels often use it. It gives buildings a modern and clean look. It also protects these parts from rain, sun, and dirt. This means they last a long time without looking old. Another big use is in consumer electronics. Think about laptop casings, tablet frames, and smartphone bodies. People want these devices to look sleek and feel premium. Clear anodizing polished aluminum gives them that look. It also makes them resistant to scratches from daily use. This helps the devices stay new for longer.

| Industry | Example Products | Benefits |

| Architecture | Building facades, curtain walls, interior design elements. | Aesthetic appeal, weather resistance, long-lasting finish. |

| Electronics | Smartphone bodies, laptop enclosures, audio equipment casings. | Premium look, scratch resistance, durability, light weight. |

| Automotive | Interior trim, exterior decorative elements, car badges. | Luxurious finish, resistance to wear and fingerprints, corrosion protection. |

| Medical | Certain instrument housings, laboratory equipment parts. | Easy to clean, durable, non-reactive surface. |

| Sporting Goods | Bicycle frames, fishing reels, high-end camping gear. | Strength-to-weight ratio, corrosion resistance, attractive appearance. |

This finish is also seen in many other places where appearance matters. For example, in high-end furniture, designer lighting fixtures, and even some kitchen appliances. People are willing to pay more for products that not only perform well but also look great and last a long time. Clear anodized polished aluminum provides this combination. It solves the problem of needing a beautiful metal that is also tough. It stands up to daily use without losing its shine. This is why it continues to be a top choice for designers and engineers.

Clear anodizing polished aluminum effectively blends beauty with strength. It gives a durable, attractive finish. This makes it ideal for many demanding applications.