Adresse

304 North Cardinal

St. Dorchester Center, MA 02124

Heures de travail

Du lundi au vendredi : de 7h00 à 19h00

Le week-end : 10H00 - 17H00

Adresse

304 North Cardinal

St. Dorchester Center, MA 02124

Heures de travail

Du lundi au vendredi : de 7h00 à 19h00

Le week-end : 10H00 - 17H00

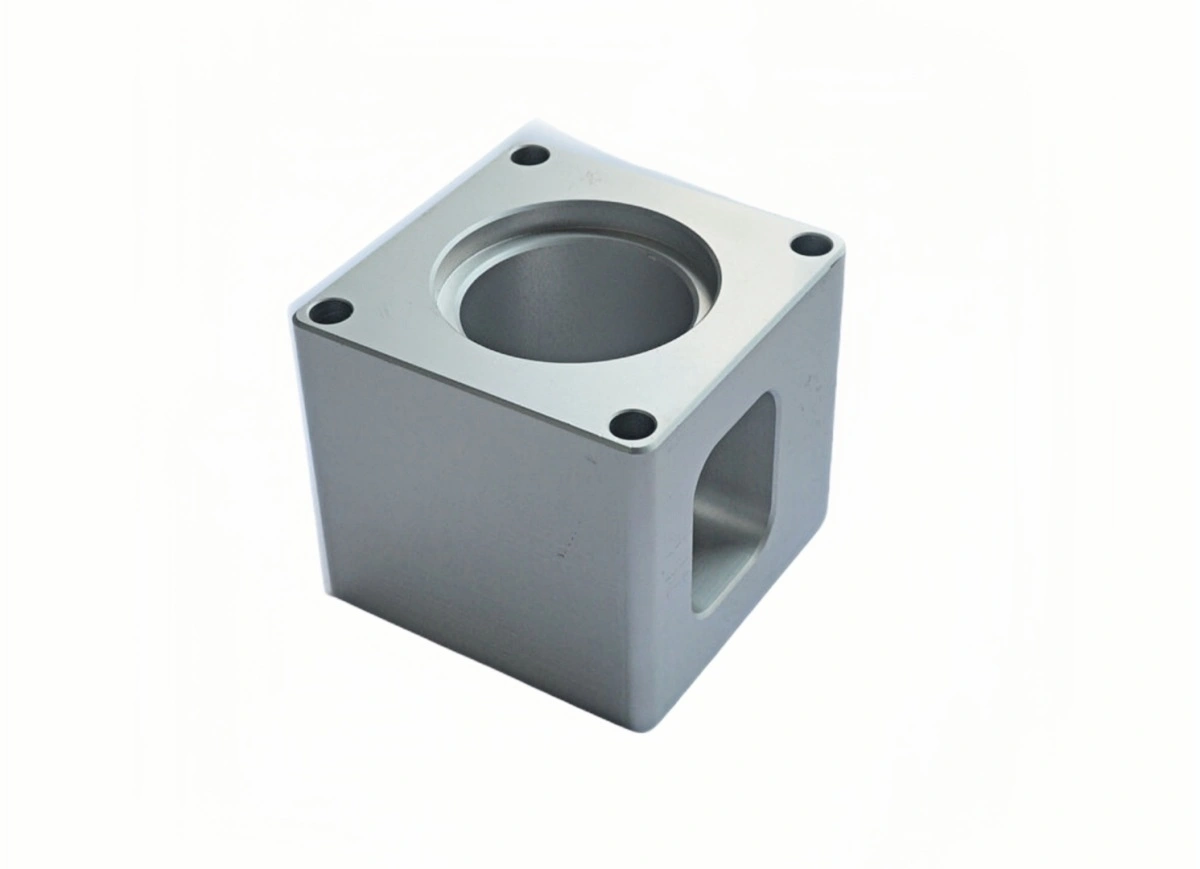

Are you struggling to find the ideal aluminum block for your CNC projects? I know that feeling – it can be a real headache. But don’t worry, I’m here to help!

The ultimate secret to finding the perfect block of aluminum for CNC, in my experience, isn’t just one thing. It’s a blend of understanding specific aluminum grades, clearly defining your project’s mechanical needs, and partnering with a knowledgeable supplier. I always tell my clients this is key.

Choosing the right material is just the start. Let’s break down how to navigate the options and ensure you get exactly what your CNC machine and project demand. This ensures your investment in a block of aluminum for cnc yields the best possible outcome.

Overwhelmed by aluminum types for your CNC work? I get it; the choices seem endless. Picking wrong means wasted material and effort, but the right one makes a huge difference for your block of aluminum for cnc.

From my perspective, the ‘best’ types of aluminum block for CNC really depend on your specific application. However, 6061 is incredibly versatile and popular for general use, while 7075 offers superior strength. I often guide clients to 6061 for its excellent machinability and good strength-to-weight ratio when they need a reliable block of aluminum for cnc.

When we talk about the “best” types, it really comes down to what you need your final part to do. I’ve worked with countless clients, and the conversation always starts with the application. Is it a structural part needing high strength? Or perhaps a part that needs good corrosion resistance? Maybe it’s a prototype where ease of machining is paramount. Each scenario points to a different “best” block of aluminum for cnc.

Let’s look at some popular choices:

Here’s a quick comparison:

| Alloy Type | Key Strengths | Common Uses for a block of aluminum for cnc | Usinabilité |

| 6061-T6 | Versatile, good strength, good machinability | General structural, machine parts, electronic enclosures | Excellent |

| 7075-T6 | Very high strength | Aerospace, high-stress parts, molds | Fair to Good |

| 2024-T3 | High strength, good fatigue resistance | Aircraft structures, transportation | Bon |

| 5052-H32 | Excellent corrosion resistance, good formability | Marine parts, sheet metal, tanks | Bon |

Understanding these basic differences is the first step. I always advise my clients to clearly define their project needs before settling on a type. This helps narrow down the options for their block of aluminum for cnc significantly.

Choosing an aluminum grade feels complex, right? I know the fear of picking a grade that’s tough to machine or doesn’t meet strength needs. Let’s clarify this for your block of aluminum for cnc.

In my professional opinion, the ‘ideal’ aluminum block grade for CNC machining balances machinability with the final part’s requirements. For many projects, 6061-T6 is a fantastic choice due to its excellent machinability and good mechanical properties. I’ve seen it work wonders time and again when selecting a block of aluminum for cnc.

When I talk about an “ideal” grade for CNC machining, several factors come into play. It’s not just about how easily the material cuts, but also about the quality of the finished part and the overall efficiency of the manufacturing process. A good block of aluminum for cnc in the right grade can save time and money.

While 6061-T6 is a great all-rounder, let’s touch on others:

The temper designation (like -T6 or -H32) is also crucial. It indicates the heat treatment or strain hardening process the aluminum has undergone, which significantly affects its mechanical properties and machinability. For example, 6061 in an annealed state (-O temper) will be much softer and gummier to machine than 6061-T6. So, when discussing a block of aluminum for cnc, specifying both the alloy and the temper is vital. I always ensure my clients understand this distinction.

Feeling unsure how to actually select the block once you know the type and grade? I’ve seen clients get stuck here. Don’t let this slow you down; I can guide you in choosing the right block of aluminum for cnc.

When I help clients select an aluminum block for CNC projects, I advise them to first consider the end-use, required strength, and desired surface finish. Then, we look at budget and machinability. This systematic approach I use ensures we pick the best material fit for their block of aluminum for cnc.

Selecting the right block of aluminum for cnc is a critical step that can significantly impact the success of your project. It’s not just about picking a material that “works”; it’s about optimizing for performance, cost, and manufacturability. I’ve developed a kind of mental checklist over the years that I walk through with my clients.

Beyond the material itself, consider your supplier:

Here’s a simple decision helper table:

| Consideration | If YES, lean towards… (Examples) |

| High Strength Needed? | 7075-T6, 2024-T3 for your block of aluminum for cnc |

| Corrosion Resistance? | 5052-H32, 6061-T6 (good, but 5052 better in marine) |

| Best Machinability? | 6061-T6, 2011-T3 (if RoHS not an issue) |

| Budget Conscious? | 6061-T6 often offers best value for general use |

| Welding Required? | 5052, 6061 for your block of aluminum for cnc |

| Extreme Stability? | MIC-6 or similar cast tooling plate |

By systematically going through these points, you can confidently select the most appropriate block of aluminum for cnc for your specific needs. It’s a process I find very effective.

Wondering if you can even get an aluminum block in the size you need? It’s a common concern I hear. Let’s talk about typical dimensions and custom options for your CNC work when sourcing a block of aluminum for cnc.

Aluminum blocks for CNC come in a wide array of standard sizes, and I often tell my customers this. From small, pre-cut pieces to large billets, many options exist. Plus, custom cutting to specific dimensions is very common for a block of aluminum for cnc, something we handle regularly.

The availability of different sizes for a block of aluminum for cnc is crucial for efficient manufacturing. You don’t want to buy a massive block if you only need a small piece, as that means more machining time and wasted material. Conversely, for large parts, you need to ensure you can source a block big enough.

Aluminum suitable for CNC machining typically comes in several forms:

When you order a block of aluminum for cnc, it’s important to understand tolerances. Standard mill tolerances for thickness, width, and length can be quite broad. If you need precise starting dimensions, you’ll often order it “oversized” and then machine it down to your final dimensions. For example, if you need a finished part that is 1.000″ thick, you might start with a block that is 1.125″ thick to allow for facing operations on both sides. I always advise my clients to account for this “clean-up” stock.

This is where a good supplier adds a lot of value. We at ALUT, for example, offer precision cutting services. This means you can order a block of aluminum for cnc cut to very near your required net size, with much tighter tolerances than standard mill stock. This can save you:

So, while there are “standard” sizes, the reality for most CNC projects is that the block of aluminum for cnc is custom cut from larger stock to meet the specific job requirements. Always discuss your size and tolerance needs with your supplier.

Picking the right block of aluminum for CNC is key. Understand types, grades, and selection for great results. We can help you succeed with your next project involving a block of aluminum for cnc.