Adresse

304 North Cardinal

St. Dorchester Center, MA 02124

Heures de travail

Du lundi au vendredi : de 7h00 à 19h00

Le week-end : 10H00 - 17H00

Adresse

304 North Cardinal

St. Dorchester Center, MA 02124

Heures de travail

Du lundi au vendredi : de 7h00 à 19h00

Le week-end : 10H00 - 17H00

Frustrated with finding the right finish for your designs? I’ve seen many projects struggle with this. The solution might be simpler and more elegant than you think: high-quality aluminum trim profiles.

Aluminum trim profiles are versatile extrusions used to provide clean edges, protect surfaces, create decorative accents, or conceal joints and gaps in various architectural, construction, and manufacturing applications. They offer both functional and aesthetic enhancements to a final product.

In this article, I’ll walk you through what makes aluminum trim profiles such a valuable component. We’ll explore their uses, types, benefits, and how to install them correctly. Let’s dive in.

I often hear from clients, “Where exactly can I use these?” You might be surprised by their versatility. Understanding their applications can spark new design ideas for your own projects.

Aluminum trim profiles are commonly used for edge protection on panels, flooring transitions, framing for screens or displays, decorative finishes on furniture and cabinetry, tile edging in kitchens and bathrooms, and architectural details on building facades.

When I talk with purchasing managers and product designers, the conversation often starts with a specific need. Perhaps they need a clean edge for a newly designed electronic enclosure, or a durable transition strip for a high-traffic commercial space. Aluminum trim profiles can meet these diverse needs.

Let’s break down some of the most popular uses:

“Okay, I see they’re useful, Wilson, but what are my options?” This is a common follow-up question I get. The variety can seem daunting, but it actually means more tailored solutions for you.

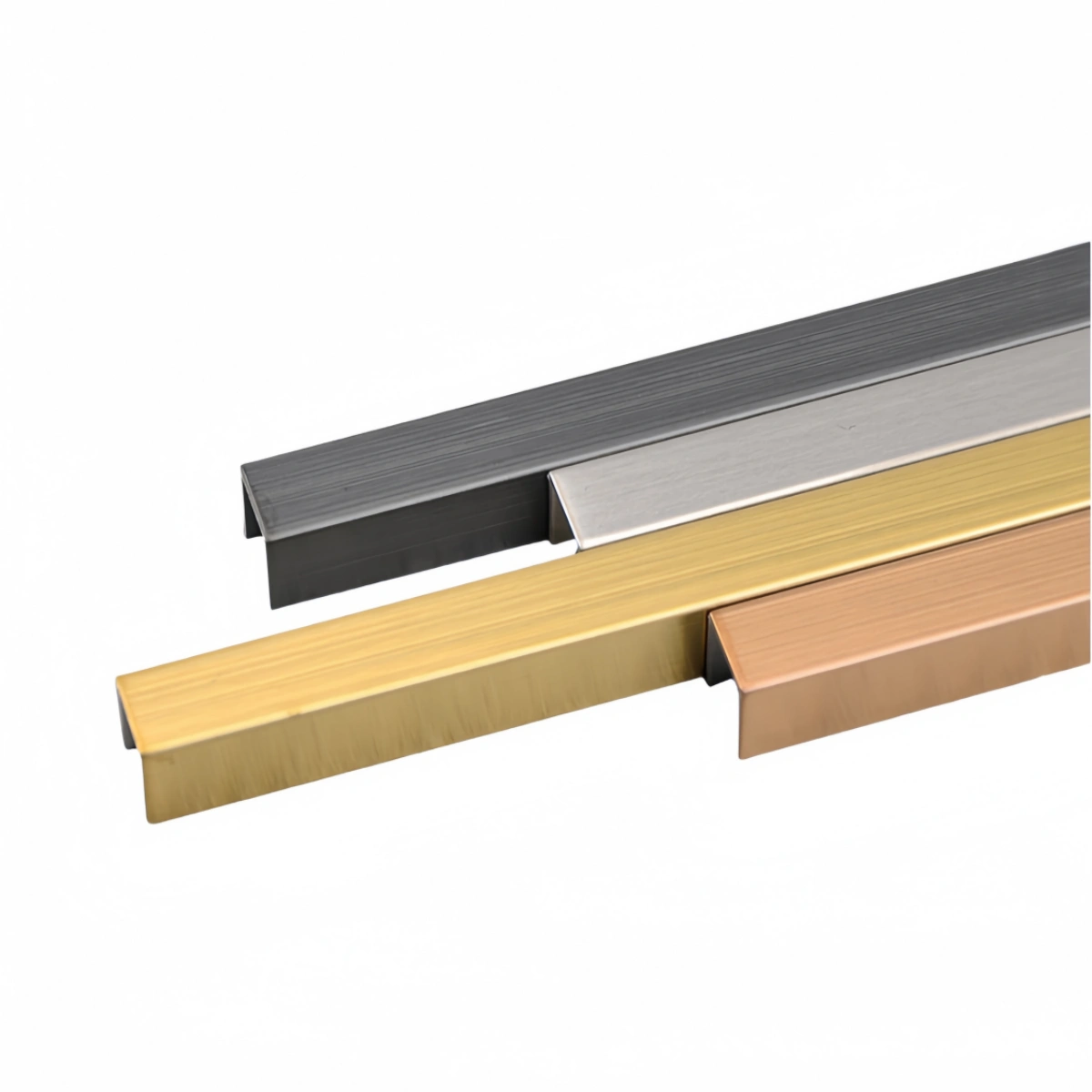

Different types of aluminum trim profiles include L-shapes, U-channels, T-shapes, F-shapes, H-shapes, round tubes, square tubes, and custom-designed extrusions. Each type serves specific functional or aesthetic purposes in various applications.

Understanding the basic shapes and their typical uses is the first step. From there, we can explore specific alloys, finishes, and even custom designs to meet precise project needs. My team and I work closely with purchasing managers to ensure they get the exact aluminum trim profiles that match their design specifications and quality expectations.

Here’s a breakdown of some standard types of aluminum trim profiles:

| Profile Shape | Common Names | Typical Uses |

| L-Shape | Angle Trim | Edge protection, corner guards, structural support, framing. |

| U-Shape | Channel Trim | Edge capping for panels (glass, wood), track for sliding doors, cable ways. |

| T-Shape | Tee Section, T-Bar | Joining two panels, covering gaps, decorative dividers, floor transitions. |

| F-Shape | – | Typically for specific glazing or panel mounting applications. |

| H-Shape | H-Channel, Joiner | Connecting two panels side-by-side, often in display systems. |

| Round Tube | Pipe | Handrails, structural elements, decorative features, conduit. |

| Square Tube | Box Section | Framing, supports, architectural elements, display stands. |

| Flat Bar | Strip | Decorative accents, support braces, edge banding. |

“Why should I choose aluminum over other materials, Wilson?” This is a crucial question for any purchasing manager focused on value and performance. I always emphasize that the material choice impacts not just cost, but also longevity and design.

The benefits of using aluminum trim profiles include their light weight, high strength-to-weight ratio, excellent corrosion resistance, recyclability, ease of fabrication, and wide range of available finishes, offering both durability and aesthetic versatility.

From my experience working with clients across the US, Canada, and Europe, these benefits directly address common manufacturing and design challenges. For example, the light weight of aluminum trim profiles can reduce shipping costs and make installation easier, while their corrosion resistance ensures longevity, even in demanding environments.

Let’s explore these benefits in more detail:

“I’ve chosen my aluminum trim profiles, Wilson. What’s the best way to install them to ensure they look good and last long?” Proper installation is key to realizing the full benefits. I’ve seen firsthand how incorrect installation can undermine even the best quality profiles.

To install aluminum trim profiles correctly, first ensure the surface is clean and level. Measure and cut the profile accurately. Then, depending on the type, secure it using appropriate fasteners like screws, adhesives, or a snap-fit mechanism, ensuring a snug fit.

Here’s a more detailed guide to help you or your teams install aluminum trim profiles:

| Aspect | Recommendation | Why it’s important |

| Measurement | Double-check all measurements before cutting any aluminum trim profiles. | Prevents wastage and ensures a perfect fit. |

| Tools | Use sharp blades designed for aluminum. | Ensures clean cuts and prevents material deformation. |

| Fasteners | Select fasteners appropriate for the aluminum and substrate material. | Ensures secure and long-lasting installation. |

| Adhesives | Use high-strength construction adhesive if screws are not desired/practical. | Provides a strong bond for a clean, fastener-free look. |

| Finition | Deburr cut edges and consider end caps for open profiles. | Enhances safety, aesthetics, and professional appearance. |

| Alignment | Use a level and ensure profiles are straight before final fixing. | Critical for visual appeal and proper function. |

In my experience, understanding the uses, types, benefits, and proper installation of aluminum trim profiles empowers you to make better design and purchasing decisions for your projects and products.

I hope this detailed look at aluminum trim profiles has been insightful. If you have specific requirements for customized aluminum products, my team at ALUT is here to provide professional and concise solutions.