Dirección

304 North Cardinal

Dorchester Center, MA 02124

Horas de trabajo

De lunes a viernes: de 7.00 a 19.00 horas

Fin de semana: 10.00 A 17.00 HORAS

Dirección

304 North Cardinal

Dorchester Center, MA 02124

Horas de trabajo

De lunes a viernes: de 7.00 a 19.00 horas

Fin de semana: 10.00 A 17.00 HORAS

Struggling with unfinished edges on your projects? It’s frustrating when a small detail compromises the entire look. I believe the solution lies in versatile j channel aluminum extrusions.

Yes, I absolutely think so. For years, I’ve seen j channel aluminum extrusions provide a clean, durable, and professional finish to countless projects. Their unique shape perfectly hides raw edges, adding structural support and a polished look that’s hard to beat.

But knowing they are useful is just the first step. To truly get the most out of them, you need to understand what they are, their real benefits, and how to use them correctly. Let’s dive in.

Heard the term but not sure what it is? This confusion can stop you from choosing the best part for your design. I’ll explain it simply, so you know exactly what you’re working with.

From my experience in the factory, j channel aluminum extrusions are simply profiles shaped like the letter ‘J’. I see them used daily to cap panels, trim edges, or create a sliding track. The design is simple but incredibly effective.

A j channel aluminum extrusion might seem basic, but its design is very specific and functional. To really understand it, let’s break it down. As a manufacturer, I see these parts every day, and their simple elegance comes from how they are made and structured.

The profile has three main parts:

These parts are formed from a single piece of aluminum. The process we use is called extrusion. We heat a solid cylinder of aluminum, called a billet, and then use a powerful hydraulic press to push it through a steel die. The die is cut into the precise shape needed to form perfect j channel aluminum extrusions. This process allows us to create very long, continuous pieces with a consistent profile. The most common alloys we use for j channel aluminum extrusions are 6063 and 6061 aluminum, known for their great finish and strength.

You can find standard-sized j channel aluminum extrusions for common panel thicknesses. However, most of our B2B clients have unique products. Their designs often require a specific dimension that isn’t standard. This is where custom extrusion becomes essential, ensuring the j channel aluminum extrusions fit their product perfectly—a critical part of quality control.

Wondering if it’s worth adding another component to your design? Choosing the wrong material can lead to rust, damage, and costly replacements. I’ll show you why this choice is a smart, long-term investment for quality.

In my opinion, the biggest benefits are durability and a clean aesthetic. I’ve found that j channel aluminum extrusions protect vulnerable edges from impact while providing a professional, finished look. They are also lightweight, corrosion-resistant, and incredibly versatile for many applications.

When a purchasing manager or engineer is deciding on components, they have to weigh the pros and cons of different materials. I have seen firsthand why aluminum is so often the best choice for manufacturing j channel aluminum extrusions. The benefits go beyond just how it looks.

Aluminum has a fantastic natural quality: it creates its own protective layer. When exposed to air, the surface of the aluminum reacts with oxygen to form a thin, hard layer of aluminum oxide. This layer seals the metal underneath from moisture and air, preventing rust and corrosion. This is a huge advantage over other materials. For a product that needs to last, using j channel aluminum extrusions is a reliable choice.

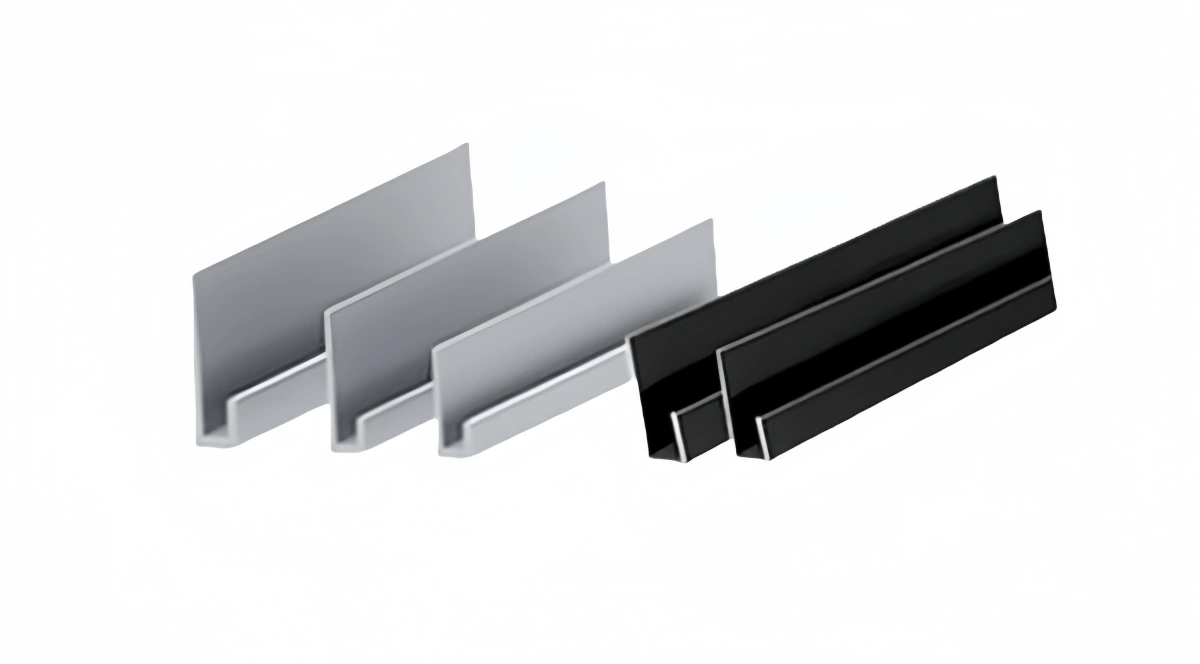

The clean lines of an extruded profile are hard to match. It gives a very modern, professional look to any edge it finishes. Beyond looking good, it’s also highly functional. We’ve produced j channel aluminum extrusions for a wide range of applications, and they can be finished in various ways—anodized, powder-coated, or painted—to match any design’s color scheme.

| Característica | J Channel Aluminum Extrusions | Steel J-Channel | Plastic J-Channel |

| Weight | Ligero | Heavy | Very Lightweight |

| Resistencia a la corrosión | Excelente | Poor (unless treated) | Excelente |

| Fuerza | Bien | Excelente | Bajo |

| Cost | Moderado | Bajo | Bajo |

| Finish Options | Many (Anodizing, etc.) | Limited (Paint, Plating) | Limited (Colored plastic) |

This simple table shows why j channel aluminum extrusions often hit the sweet spot for many projects. They offer a great balance of performance and cost.

Worried about a difficult installation process? A bad installation can ruin the part and the entire project, wasting time and materials. I’ll walk you through the simple, key steps for a perfect, secure fit every time.

I always advise my clients to focus on three things for a proper installation: precise measurement, a clean cut, and the right fastener. I’ve seen the best results when the channel is secured firmly with screws or adhesive, ensuring there is no movement.

Even the best j channel aluminum extrusions can be let down by poor installation. In my years of manufacturing, I’ve also learned a lot from my customers about what works in the field. Proper installation ensures the part not only looks good but also performs its protective function correctly.

This is the most critical step. The old rule “measure twice, cut once” is very important when working with j channel aluminum extrusions. Use a quality tape measure to determine the exact length you need. Before you cut, also make sure the surface you’re attaching the channel to is clean and dry. Any dirt or oil can prevent adhesives from sticking properly.

The tool you use matters. To get a clean, burr-free cut on j channel aluminum extrusions, I recommend a miter saw equipped with a non-ferrous metal cutting blade. These blades have more teeth and a specific geometry that slices through aluminum without tearing it. A rough cut looks unprofessional and can create a gap where dirt and moisture can get in. Always wear safety glasses when cutting.

| Step # | Action | Key Tip |

| 1 | Measure the edge | Double-check your measurement before marking the channel. |

| 2 | Mark the cut line | Use a fine-tip marker and a square for a straight line. |

| 3 | Cut the channel | Use a miter saw with a non-ferrous blade for the cleanest cut. |

| 4 | Test the fit | Place the cut piece on the panel to ensure it’s the correct length. |

| 5 | Secure the channel | Use appropriate screws or adhesive based on the application. |

How you attach the j channel aluminum extrusions depends on the application. For a permanent, high-strength bond, small screws drilled through the back leg of the channel are best. If you don’t want any visible fasteners, a strong construction adhesive is an excellent choice.

Overwhelmed by different sizes and dimensions? Choosing the wrong size leads to a poor fit, returns, and project delays. I’ll give you a clear method to select the perfect size for your application.

From my experience, choosing the right size is all about the “channel opening.” I always tell my team to measure the thickness of the panel or material it will cover. The opening should be just slightly larger to allow for an easy but snug fit.

Choosing the correct size for your j channel aluminum extrusions is fundamental. This is where many projects go wrong and where a supplier’s precision really matters. As a purchasing manager, getting this right saves you from the headache of returns and production delays.

There are three measurements you must know for a j channel aluminum extrusion:

This is where professional suppliers stand out. “Tolerance” refers to the acceptable range of variation in a dimension for j channel aluminum extrusions. Poor quality control can lead to parts being outside this tolerance, causing huge assembly problems. At ALUT, we manage this with strict process controls and quality inspections, a key part of the project management service we provide.

| Panel Thickness | Recommended Channel Opening | Typical Use Case for J Channel Aluminum Extrusions |

| 1/8″ (0.125 in) | ~0.135 in | Thin acrylic sheets, signage |

| 1/4″ (0.250 in) | ~0.260 in | Standard plywood, glass panels |

| 1/2″ (0.500 in) | ~0.515 in | Thicker composite panels, shelving |

| 3/4″ (0.750 in) | ~0.765 in | Cabinetry, furniture panels |

When you cannot find standard j channel aluminum extrusions that provide the perfect fit, you need a custom solution. This is very common for original equipment manufacturers (OEMs). They send us their drawings, and we create a profile with the exact dimensions their product requires.

In short, j channel aluminum extrusions offer a superior finish and durability. Understanding them is key. For your custom projects requiring precision and reliability, my team and I at ALUT are ready to help.