Dirección

304 North Cardinal

Dorchester Center, MA 02124

Horas de trabajo

De lunes a viernes: de 7.00 a 19.00 horas

Fin de semana: 10.00 A 17.00 HORAS

Dirección

304 North Cardinal

Dorchester Center, MA 02124

Horas de trabajo

De lunes a viernes: de 7.00 a 19.00 horas

Fin de semana: 10.00 A 17.00 HORAS

Are you struggling to find strong, lightweight components for your big projects? The challenges of traditional manufacturing can be frustrating.

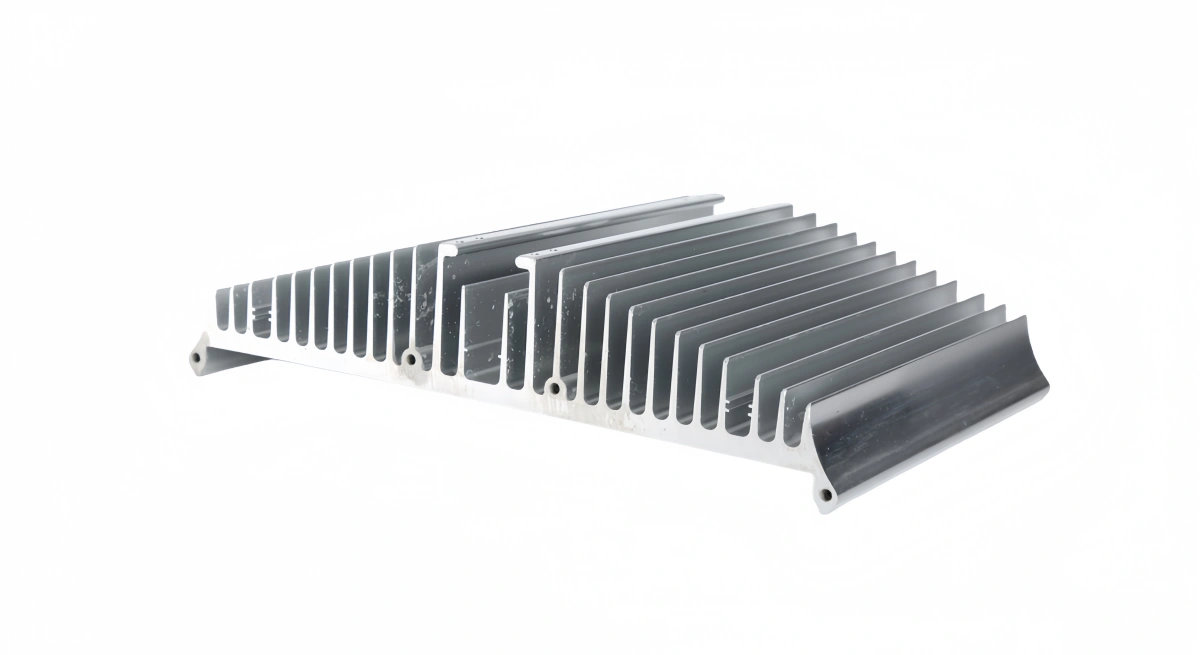

Large aluminum extrusions offer a superior solution for demanding applications, providing high strength-to-weight ratios and design flexibility that conventional materials cannot match, proving essential for modern industrial needs.

Let’s explore how large aluminum extrusions can unlock new possibilities for your toughest designs.

Are you wondering what makes an aluminum extrusion “large”? It’s more than just a matter of size, isn’t it?

Large aluminum extrusions are defined by their cross-sectional dimensions, typically exceeding 6-8 inches, or requiring high tonnage presses for production. These substantial profiles are critical for applications demanding significant structural integrity and broad spans.

When we talk about large aluminum extrusions, we are often looking at profiles that cannot be made on standard presses. The size and complexity demand specialized equipment and deeper engineering knowledge. Typically, an extrusion is considered large when its circumscribing circle diameter (CCD) is greater than 8 inches. The CCD is the smallest circle that can completely enclose the cross-section of the extrusion. Some large aluminum extrusions can have a CCD of over 20 inches. This requires powerful presses with capacities ranging from 3,000 to over 10,000 tons. These presses exert immense force to push aluminum through the die.

The manufacturing process for large aluminum extrusions is more complex than for smaller ones. The dies are larger and more expensive to produce. They also experience more stress during extrusion. This means that die design and material selection are crucial. Cooling rates for large profiles are also different. They need careful control to ensure consistent metallurgical properties throughout the length. This prevents warping or internal stresses. We ensure that our large aluminum extrusions meet precise specifications. Our quality control team checks every step. This commitment helps us avoid the common pain point of product dimensional tolerances not meeting design requirements.

Consider the distinctions below:

| Characteristic | Standard Extrusions | Large Aluminum Extrusions |

| CCD (Circumscribing Circle Diameter) | Up to 8 inches | Over 8 inches (often 12-24 inches or more) |

| Press Tonnage | Typically 1,000-3,000 tons | Often 3,000-10,000+ tons |

| Die Size/Cost | Smaller, lower cost | Larger, higher cost, complex design |

| Typical Wall Thickness | Thinner | Thicker, up to several inches |

| Aplicaciones | General purpose, consumer goods | Structural, heavy industry, transportation |

These factors highlight why large aluminum extrusions are a specialized product. They require manufacturers with specific expertise and equipment.

Are you curious about where large aluminum extrusions are actually used? Their applications are surprisingly diverse, aren’t they?

Large aluminum extrusions are vital for industries requiring robust, lightweight structural components, including transportation, construction, marine, and renewable energy sectors, where they provide superior strength and design integration.

Large aluminum extrusions find their place in a wide range of demanding applications. Their unique combination of strength, light weight, and corrosion resistance makes them ideal for sectors where performance is critical. In transportation, they are used for railway cars, truck trailers, and bus frames. They reduce the vehicle’s weight. This improves fuel efficiency. It also increases payload capacity. In the construction industry, large aluminum extrusions form structural elements for buildings. They are used in curtain walls, bridge decks, and large architectural facades. Their ability to create complex, integrated profiles simplifies construction and improves aesthetics.

One key advantage in these applications is the ability to consolidate multiple parts into a single large aluminum extrusion. For instance, a single profile can integrate structural support, mounting channels, and thermal management fins. This reduces the number of parts to assemble. It lowers production costs. It also improves the overall integrity of the final product. Our company focuses on providing these customized solutions. We understand that purchasing managers need parts that perform reliably in their end products, whether those are LED lights, electric appliances, or industrial machines.

Here is a table showing typical uses:

| Industry Sector | Example Applications for Large Aluminum Extrusions | Beneficio clave |

| Transportation | Railway car bodies, truck chassis, bus frames | Weight reduction, fuel efficiency, structural integrity |

| Construction | Building facades, bridge decks, structural beams | Design flexibility, corrosion resistance, ease of assembly |

| Renewable Energy | Solar panel frames, wind turbine structures | Durability, weather resistance, structural support |

| Industrial Equipment | Machine frames, heavy-duty enclosures, automation bases | Strength, rigidity, integrated functionality |

The diverse uses of large aluminum extrusions demonstrate their value. They are an essential component for many advanced industrial products.

Are you feeling overwhelmed trying to pick the right supplier for large aluminum extrusions? Finding a capable partner can be a big challenge, right?

Selecting manufacturers for large aluminum extrusions requires focusing on their press capacity, engineering expertise, advanced quality control, and experience with complex profiles, ensuring they can meet your project’s specific demands.

Choosing the right manufacturer for large aluminum extrusions is a critical decision. It impacts the quality, cost, and timely delivery of your components. The first thing to check is their equipment. Do they have the high-tonnage presses needed for large profiles? Manufacturing large aluminum extrusions requires presses with capacities of 3,000 tons or more. Without this equipment, they simply cannot produce the parts. Next, evaluate their engineering team. Large extrusions often have complex designs. You need a manufacturer who can provide design assistance. They should help optimize your profile for both performance and manufacturability. This avoids costly redesigns later.

My company, ALUT, understands these challenges well. We are a B2B wholesaler based in China. We operate a factory over 10,000 square meters. We specialize in customized aluminum products, including large aluminum extrusions. Our service team provides complete supply chain management. This includes order management, quality control, and logistics. We export to the United States, Canada, and Europe. We know that clear communication and precise quality control are vital, especially for large and complex parts.

Here is a table to guide your selection process:

| Factor | What to Look For | Why It Matters |

| Equipment & Capacity | High-tonnage presses, large ovens, long beds | Directly impacts ability to produce large aluminum extrusions |

| Technical Knowledge | Experienced engineers, DFM services, alloy expertise | Ensures optimal design and prevents production issues |

| Quality Assurance | ISO certification, strict inspection, material traceability | Guarantees parts meet specifications and prevents defects |

| Logistics Support | Packaging expertise, international shipping experience | Ensures safe, on-time delivery of large, often heavy, parts |

| Communication | Responsive team, clear reporting, English proficiency | Prevents misunderstandings, especially with overseas suppliers |

By focusing on these key areas, you can select manufacturers for large aluminum extrusions that will be a reliable partner for your most demanding projects.

Are you unsure how different aluminum alloys affect the performance of large extrusions? The right alloy choice is critical, isn’t it?

Aluminum alloys significantly impact large aluminum extrusions’ performance by determining their strength, corrosion resistance, weldability, and thermal properties, making careful selection crucial for meeting specific application requirements.

The choice of aluminum alloy is a fundamental decision when working with large aluminum extrusions. Each alloy possesses a unique blend of mechanical, physical, and chemical properties. These properties directly influence how the large extrusion will perform in its intended application. For example, some alloys are designed for maximum strength, while others prioritize corrosion resistance or weldability.

The selection of the alloy directly affects the part’s integrity and lifespan. For example, a large aluminum extrusion used in a marine environment will need excellent corrosion resistance. This points to a 6xxx series alloy. A part for an aircraft might need maximum strength, leading to a 7075 alloy. We work closely with our clients to specify the best alloy for their large aluminum extrusions.

Here is a quick reference for alloy impacts:

| Alloy Type | Primary Impact on Performance | Ideal for Large Aluminum Extrusions in… |

| 6061 | Good balance of strength, corrosion resistance, weldability | Structural, general engineering, transportation |

| 6063 | Excellent surface finish, good corrosion resistance, moderate strength | Architectural, decorative, visible components |

| 6005/6005A | Higher strength than 6063, good formability | Heavy-duty structural, railway, industrial machinery |

| 7075 | Very high strength, fatigue resistance | Aerospace, high-stress, critical applications |

Understanding these alloy differences is key to optimizing the performance of your large aluminum extrusions.

Large aluminum extrusions are game-changers for demanding industries. Choose a manufacturer with robust capabilities and expertise to ensure project success.

Name: Wilson Yau

Correo electrónico: [email protected]

Website: https://www.lt-aluminum.com

Brand name: ALUT

Country: China

Products: customized aluminum products

Business model: B2B, wholesale only. We are our factory with an area of more than 10,000 square meters, with factories in China. Customers place orders with us, and our service team provides complete supply chain services, including order management, quality control, and logistics management.

Current operations: Headquartered in China, China (200 employees).

Main export countries: United States, Canada,Europe

Potential customer profile: Buyers or executives of large companies, purchasing managers, or product managers of manufacturers.

Product features: Made in Vietnam or Made in China, standard products can be provided or customized according to drawings or samples provided by customers.

Marketing channels: website, Alibaba, LinkedIn