Dirección

304 North Cardinal

Dorchester Center, MA 02124

Horas de trabajo

De lunes a viernes: de 7.00 a 19.00 horas

Fin de semana: 10.00 A 17.00 HORAS

Dirección

304 North Cardinal

Dorchester Center, MA 02124

Horas de trabajo

De lunes a viernes: de 7.00 a 19.00 horas

Fin de semana: 10.00 A 17.00 HORAS

Have you ever faced unexpected project delays or quality issues? I know how frustrating that can be. It often comes down to the right manufacturing choices.

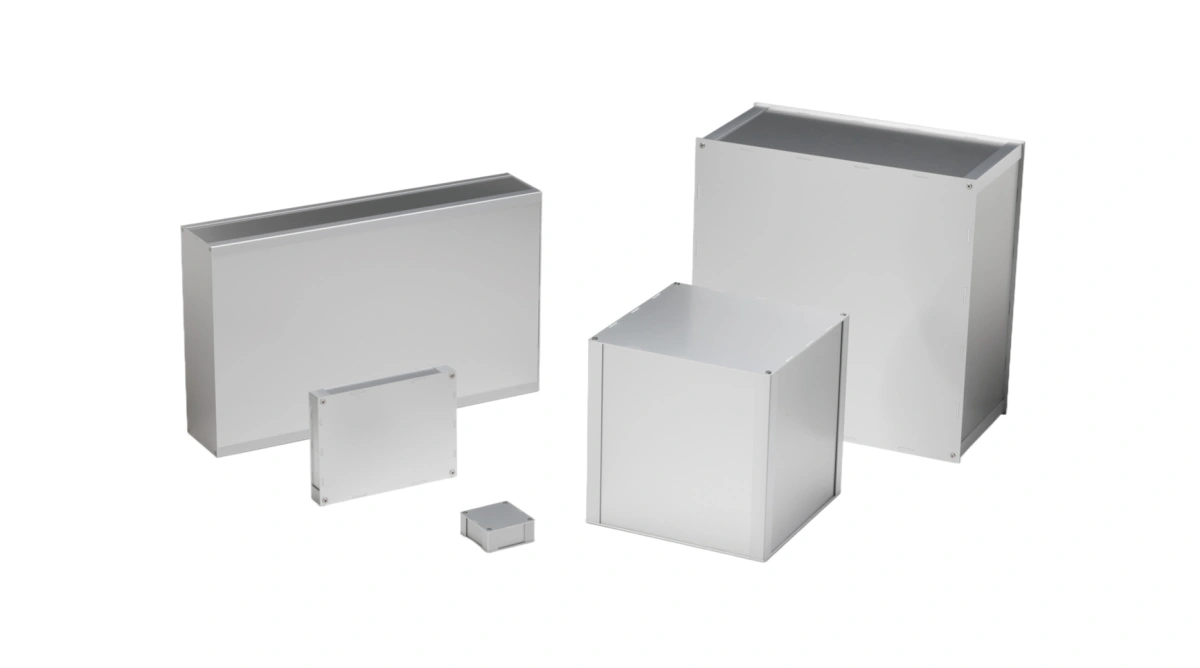

We’ve discovered that aluminum extrusion services are essential for achieving precise, high-quality components, helping projects stay on schedule and within budget. These services offer unparalleled design flexibility and material integrity for various applications.

Stay with me as we explore how these specialized services can truly transform your manufacturing process and prevent those painful project headaches.

Are you wondering how aluminum extrusion services can genuinely help your projects? I’ve seen firsthand the significant impact they make on manufacturing outcomes.

From our experience, aluminum extrusion services provide unmatched design freedom and consistent material properties, leading to stronger, lighter, and more cost-effective products. This directly improves project efficiency and overall product performance.

Aluminum extrusion services bring many benefits to your projects. First, they offer great design flexibility. You can create complex shapes and custom profiles that are hard to get with other manufacturing methods. This means your designs can be more innovative and perfectly fit your specific needs. For example, if you need a part with special grooves or channels for wiring, aluminum extrusion services can easily make it. This flexibility helps engineers and designers to think outside the box and create better products.

Second, using aluminum extrusion services leads to products with a high strength-to-weight ratio. Aluminum is naturally light, but the extrusion process makes it very strong. This is important for many industries, like aerospace and automotive, where reducing weight is crucial for fuel efficiency and performance. Imagine making a frame for an electronic device. If it’s light but strong, the device is easier to handle and more durable.

Third, aluminum extrusion services can help reduce costs. Even though the initial tooling cost might seem high, the long-term savings are significant. This is because aluminum extrusion services allow for mass production of consistent parts, reducing material waste and assembly time. For example, if you design a complex part that needs many individual pieces welded together, an extruded profile can make it as one piece. This saves time and money on assembly. Also, aluminum is recyclable, which lowers material costs over time and is better for the environment.

Here is a simple breakdown of the benefits:

| Beneficio | Descripción |

| Flexibilidad de diseño | Create complex, custom shapes and profiles. |

| Strength-to-Weight | Get strong parts that are also light. |

| Cost Efficiency | Reduce material waste and assembly time, lower production costs. |

| Durability | Extruded parts are robust and last longer. |

| Acabado superficial | Good surface for anodizing or painting. |

Finally, aluminum extrusion services ensure consistent quality. The extrusion process is highly controlled, which means every piece you get will meet the exact specifications. This is vital for maintaining product quality and reliability, especially in critical applications. For example, if you are making parts for medical equipment, precision and consistency are not just important; they are mandatory. Aluminum extrusion services help meet these strict requirements every time.

Are you curious about the different kinds of aluminum extrusion services out there? I often get asked this question, and the variety is truly impressive.

Based on our extensive experience, aluminum extrusion services range from standard profile creation to complex custom designs, including various finishing options like anodizing and powder coating, ensuring a perfect fit for diverse project needs.

Let’s look at the main types of aluminum extrusion services that can serve your project’s unique demands.

There are many types of aluminum extrusion services, each designed for specific needs. The most common type is direct extrusion. In direct extrusion, a heated aluminum billet is pushed through a die opening. This creates a continuous profile. This method is good for making solid and hollow shapes. It is widely used for architectural components, heat sinks, and structural parts. For example, window frames are often made using direct extrusion because it can create long, consistent pieces.

Another type is indirect extrusion. With indirect extrusion, the die moves through a stationary billet. This process creates less friction and needs less force. This means it can produce more consistent profiles and parts with better surface finishes. Indirect extrusion is often used for specialized applications where high precision is important. It is less common than direct extrusion but offers advantages for certain designs.

Beyond the basic extrusion process, aluminum extrusion services also include many secondary operations. These operations add value and make the extruded parts ready for use. One important secondary service is cutting. Extruded profiles come in long lengths, but most projects need shorter, precise pieces. So, cutting services cut the profiles to the exact length you need. This often involves very accurate saws.

Here are some common secondary services:

Finally, some aluminum extrusion services offer assembly and packaging. They can put together different parts to create a complete product. Then, they package it for shipping. This full-service approach can save you time and effort. It streamlines your supply chain. When you choose aluminum extrusion services, you consider all these options to find the best fit for your project.

Are you trying to figure out what drives the costs of aluminum extrusion services? I know how critical it is to manage budgets, and understanding these factors is key.

I’ve observed that aluminum extrusion service costs are primarily affected by die complexity, alloy type, order volume, and any required secondary operations like finishing or machining, making a detailed quote essential for accurate budgeting.

Let’s break down the main factors that impact the price you’ll pay for aluminum extrusion services.

Several factors influence the costs of aluminum extrusion services. Understanding these helps you manage your budget better. First, the complexity of the die design is a major cost driver. The die is the tool that shapes the aluminum. If your profile is very simple, the die will be cheaper to make. If it has many intricate details, sharp corners, or hollow sections, the die will be more expensive. This is because complex dies need more precise engineering and manufacturing. For example, a simple square tube die costs less than a complex heat sink profile die.

Second, the type of aluminum alloy used affects the cost. Different aluminum alloys have different properties and prices. Some common alloys are 6061 and 6063. Alloy 6063 is often used for architectural purposes because it has a good surface finish and is easy to extrude. Alloy 6061 is stronger and used for structural applications. More specialized or stronger alloys generally cost more per pound. So, choosing the right alloy means balancing performance needs with cost.

Third, the volume of your order plays a big role in pricing. Like most manufacturing processes, larger orders usually lead to lower per-unit costs for aluminum extrusion services. This is because the setup costs for the extrusion press and the die are spread over more units. Small orders might have higher per-unit costs because those fixed setup costs are divided among fewer items. If you need a small quantity of a custom profile, the cost per piece will be higher than if you order thousands of the same profile.

Here is a summary of cost influences:

| Factor | Impact on Cost |

| Die Complexity | More complex shapes mean higher die costs. |

| Aluminum Alloy Type | Specialty or stronger alloys cost more. |

| Order Volume | Larger orders reduce per-unit cost. |

| Secondary Operations | Machining, finishing, and fabrication add to cost. |

| Acabado superficial | Anodizing or powder coating increases the total price. |

Fourth, any secondary operations you need will add to the total cost. These include cutting, machining, drilling, and welding. Each additional process needs labor, specialized machines, and time, which increases the price. For instance, if you need an extruded profile to be cut to specific lengths and then drilled with precise holes, these steps add to the base extrusion cost. We offer many of these services.

Fifth, surface finishes also affect the cost. Options like anodizing, powder coating, or painting provide different levels of protection and aesthetic appeal. Anodizing, for example, is a common finish that improves corrosion resistance and allows for various colors. Each type of finish has its own cost based on the materials used and the process involved. Choosing a specific finish adds to the overall price of the aluminum extrusion services. All these factors combine to determine the final price of your extruded parts.

Are you wondering how to pick the perfect aluminum extrusion service provider? I’ve seen many businesses struggle with this, and making the right choice is absolutely critical for project success.

From my extensive background, selecting the best aluminum extrusion service provider requires evaluating their engineering expertise, quality control systems, project management capabilities, and overall commitment to reliable logistics and clear communication.

Let’s explore the key steps to finding a provider that truly meets your needs and avoids common pitfalls.

Choosing the best aluminum extrusion service provider is very important for your project’s success. First, look at their engineering design capabilities. A good provider should have experienced engineers who can help with your design. They should be able to give advice on how to optimize your profile for extrusion. This means making sure your design is both functional and cost-effective to produce. For example, if your design has very thin walls, they might suggest a slight change to improve manufacturability without changing its function. This kind of expertise helps avoid problems later.

Second, assess their quality control system. Quality is key. You need a provider who can ensure that all parts meet your exact specifications. Ask about their quality inspection processes. Do they do checks at every stage of production? Do they use advanced measuring tools? For instance, we have a robust quality control system to ensure product dimensional tolerances and specifications meet design requirements. This prevents issues like delayed delivery or products that do not fit.

Third, consider their project management and communication skills. You need a provider who is easy to work with and communicates clearly. This means they should give you regular updates and respond quickly to your questions. A provider with strong project management skills will keep your project on track and on time. Poor communication from a sales representative can lead to misunderstandings and delays, which can stop your production. We focus on clear and professional communication.

Here is a checklist for choosing a provider:

| Criterion | Questions to Ask |

| Engineering Expertise | Can they help optimize my design for extrusion? |

| Control de calidad | What are their quality inspection processes? |

| Project Management | How do they manage timelines and communicate progress? |

| Supply Chain Services | Do they offer logistics, order management, and quality control? |

| Experience & Reputation | How long have they been in business? Can they provide references? |

Fourth, look at their supply chain services. Do they offer more than just extrusion? A comprehensive provider can help with supplier procurement, supplier audits, contract manufacturing, and logistics management. This means they can handle the entire process from start to finish. For example, we offer complete supply chain services, including order management, quality control, and logistics management. This makes the whole process smoother for you.

Finally, think about their location and production capacity. If you are looking to purchase from China or Vietnam, like many buyers today, find a provider with factories in those regions. This can help with tariffs and shipping costs. Also, make sure they have the capacity to handle your order size, whether it’s large or small. We have factories in China and export to the United States, Canada, and Europe. By carefully considering these points, you can choose an aluminum extrusion service provider that is a reliable partner for your projects.

Choosing the right aluminum extrusion services is vital. It impacts design flexibility, cost, and overall product quality. Focus on expertise, quality control, and strong communication for success.