Dirección

304 North Cardinal

Dorchester Center, MA 02124

Horas de trabajo

De lunes a viernes: de 7.00 a 19.00 horas

Fin de semana: 10.00 A 17.00 HORAS

Dirección

304 North Cardinal

Dorchester Center, MA 02124

Horas de trabajo

De lunes a viernes: de 7.00 a 19.00 horas

Fin de semana: 10.00 A 17.00 HORAS

Struggling with cracked or uneven aluminum bends? This waste of material and time is a common frustration. I’ll show you how I get perfect results every time.

From my extensive experience, flawlessly bending aluminum plate isn’t about luck; it’s a science. It requires a deep understanding of the material’s properties, using the right tools like a press brake, and precisely controlling the bending process, especially the bend radius and speed.

Now, let’s dive into the specifics. Getting this right is crucial for any project, and I’m here to walk you through the exact steps and methods that we use in our factory to deliver top-quality parts to clients just like you.

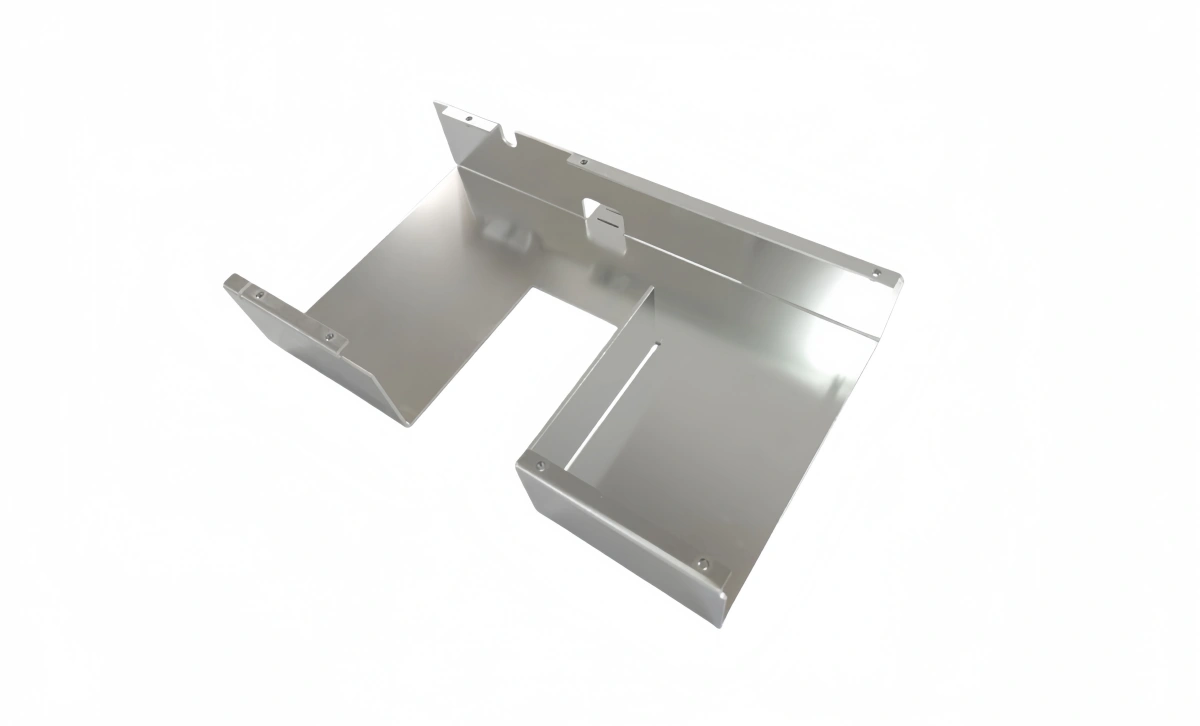

You have a design, but don’t know the exact steps to turn that flat sheet into a finished part. This uncertainty can lead to costly mistakes. I’ll outline the exact process we follow.

I always start the process by selecting the right alloy and inspecting the material. Then, my team prepares the plate, sets up the press brake with the correct tooling, and performs the bend slowly and carefully to prevent any fractures or defects.

The process for bending aluminum plate is a systematic procedure that demands precision at every stage. It’s not just about applying force; it’s about controlled deformation. Let’s break down the core steps we take to ensure high-quality results for our B2B clients who need expertly bent parts.

The first decision is always the most critical: choosing the right aluminum alloy and temper for the job. Different alloys have vastly different properties when it comes to forming. For example, 5052 aluminum is known for its excellent formability, making it a go-to choice for projects that require complex bending aluminum plate. In contrast, an alloy like 6061-T6 is much stronger but more brittle, requiring a larger bend radius to avoid cracking.

Once the material is selected, we inspect it for any surface defects. The plate’s edges are then deburred. Sharp or rough edges are stress concentration points and are a primary cause of cracking during the bend. This preparation is a non-negotiable step in our quality control for bending aluminum plate.

With the material ready, we move to the press brake. The key here is selecting the correct punch and V-die. The opening of the V-die is directly related to the inside bend radius you will achieve. A wider V-die opening results in a larger, more gradual bend radius, which is essential for successfully bending aluminum plate.

We also calculate the bend allowance. This essential calculation determines the total flat length of the material needed to achieve the desired dimensions after bending. Incorrect calculations lead to parts that don’t meet spec, a problem our clients need to avoid.

The final step is the actual bending. The aluminum plate is carefully positioned on the V-die. The press brake ram descends, pushing the punch into the plate. The key here is control. We apply pressure slowly and steadily. Rushing the bending aluminum plate process can shock the material, increasing the likelihood of fractures. After the initial bend, we use a protractor to check the angle and make micro-adjustments to meet the exact design requirements.

There seem to be several ways to bend metal, but which one is right for your project? Choosing the wrong one can ruin your parts and your budget. I’ll tell you the most reliable method.

In my professional opinion, using a press brake is the best method for bending aluminum plate in a manufacturing setting. It provides the precision, control, and repeatability that our clients demand for their high-quality custom products.

When a purchasing manager asks for a “bent aluminum part,” they are almost always picturing a component formed on a press brake. This machine is the industry standard for bending aluminum plate for a reason. Its superiority lies in its versatility and precision, which are essential for the custom parts we produce for clients in the US and Europe.

Inside the world of press brake operations, there are three primary techniques for bending aluminum plate. The choice depends on the required precision, material, and tooling.

| Bending Method | Descripción | Best For |

| Air Bending | The punch presses the plate into the V-die, but it doesn’t touch the bottom. The bend angle is controlled by how far the punch descends. | The most common and flexible method for bending aluminum plate. Good for most applications and requires less tonnage. |

| Bottoming | The punch presses the material fully against the walls of the V-die. This “sets” the material and reduces springback. | Applications needing higher precision and a more defined radius than air bending. |

| Coining | An extremely high-force method where the punch tip penetrates and thins the material at the bend line, stamping the radius permanently. | Very high precision and repeatability, but requires immense force and specific tooling. It is less common for aluminum. |

For most projects involving bending aluminum plate, we rely on air bending. It provides an excellent balance of precision and efficiency. It allows us to use one set of V-dies to create a variety of bend angles simply by adjusting the stroke depth of the ram. This flexibility is key in a custom manufacturing environment where part designs vary greatly. Bottoming is reserved for jobs where springback is a major concern.

You think you can just grab a hammer and a vise? Using the wrong equipment for bending aluminum plate will lead to poor results and can even be dangerous. Here is the essential toolkit I use.

For a professional job, I always rely on a press brake as the primary machine. Equally important are the specific punches and dies matched to the job, plus precision measuring tools like digital calipers and protractors.

Having the right tools is non-negotiable for quality and safety. In our factory, we view our tooling as an investment in our clients’ success. A project’s quality is directly tied to the quality of the tools used to produce it. Let’s look at the essential equipment for bending aluminum plate.

The press brake is the heart of the operation. Modern CNC press brakes, like the ones we use at ALUT, have revolutionized the task of bending aluminum plate. We can program the exact bend angle, back gauge position, and ram speed. This automation ensures that every part in a production run is identical. This repeatability is something purchasing managers value highly, as it guarantees consistency in their final assembled products like LED lights or industrial machines.

The punch and die are what shape the metal. They are not one-size-fits-all. The selection is critical when bending aluminum plate.

Here is a simple guide we often refer to:

| Aluminum Thickness | Recommended V-Die Opening |

| 1.5 mm (0.060 in) | 12 mm (0.472 in) |

| 3.0 mm (0.125 in) | 25 mm (1.000 in) |

| 6.0 mm (0.250 in) | 50 mm (2.000 in) |

You cannot control what you cannot measure. After bending aluminum plate, every part is checked. We use:

That dreaded cracking sound is the noise of wasted money and time. It’s a frustrating problem. I’ve learned the secrets to prevent this, and I’ll share them with you now.

From years of trial and error, I can tell you that the secret to preventing cracks when bending aluminum plate is to always bend across the grain, use a large bend radius, and choose a softer, more formable alloy.

Preventing cracks is the true test of a fabricator’s skill. It’s where deep material understanding separates the experts from the amateurs. For our clients, receiving cracked parts is unacceptable, as it compromises the integrity of their final product. Let’s explore the key factors in crack-free bending aluminum plate.

Like wood, rolled aluminum has a grain direction. This is the direction in which the material was stretched during the rolling process. Bending parallel to this grain forces the material to separate along these lines, leading to cracks.

The solution is simple: always orient the part so the bend line goes across the grain. This forces the grains to stretch together. Understanding this is a professional secret for successful bending aluminum plate. Sometimes, the grain is not visible, so we perform a test bend on scrap to confirm orientation.

The single biggest cause of cracking when bending aluminum plate is trying to create a bend that is too sharp. A sharp bend concentrates stress into a tiny area. A larger, more gradual bend radius distributes that stress, greatly reducing the risk of failure. A generous bend radius is the most important safety measure for bending aluminum plate.

| Alloy & Temper | Minimum Bend Radius (Rule of Thumb) | Formability |

| 5052-H32 | 1-2 x Thickness | Excelente |

| 3003-H14 | 0-1 x Thickness | Excelente |

| 6061-T4 | 2-3 x Thickness | Bien |

| 6061-T6 | 5-7 x Thickness | Poor |

Forcing a 6061-T6 plate into a sharp bend is a guaranteed failure. We always advise our clients on realistic bend radii for their chosen materials during the design review. This is part of the professional service that prevents problems down the line.

Mastering the art of bending aluminum plate requires the right knowledge, tools, and technique. Focus on these fundamentals—material choice, bend radius, and process control—and your projects will be a success.