Dirección

304 North Cardinal

Dorchester Center, MA 02124

Horas de trabajo

De lunes a viernes: de 7.00 a 19.00 horas

Fin de semana: 10.00 A 17.00 HORAS

Dirección

304 North Cardinal

Dorchester Center, MA 02124

Horas de trabajo

De lunes a viernes: de 7.00 a 19.00 horas

Fin de semana: 10.00 A 17.00 HORAS

Tired of seeing kinked or cracked aluminum pipes in your projects? This common failure wastes time and money. I will show you the professional approach to get it right.

In my professional experience, the ultimate secret to flawless bending of aluminum pipe is not one trick, but a system: selecting the right method like mandrel bending, using proper internal support to prevent kinking, and respecting the material’s properties by avoiding unnecessary heat.

Let’s dive into the specifics. By understanding these key areas, you can ensure the custom aluminum parts you order meet the high-quality standards your projects demand.

Are you getting inconsistent results from your current fabrication methods? Choosing the wrong process for bending aluminum pipe is a direct path to poor quality and rejected parts.

I always tell my team that for high-quality, precision work, mandrel bending is the best method. It provides internal support to create a smooth, round bend without collapsing the pipe, which is critical for our clients’ demanding applications.

The method used for bending aluminum pipe directly impacts the final part’s structural integrity and appearance. As a purchasing manager, you don’t need to operate the machine, but understanding the different methods helps you specify your requirements clearly. A cheap quote might come from a supplier using an inferior method, which can lead to quality problems. At our facility, we match the bending method to the part’s specific requirements, including its diameter and wall thickness. This ensures we deliver consistent quality for every order involving the bending of aluminum pipe.

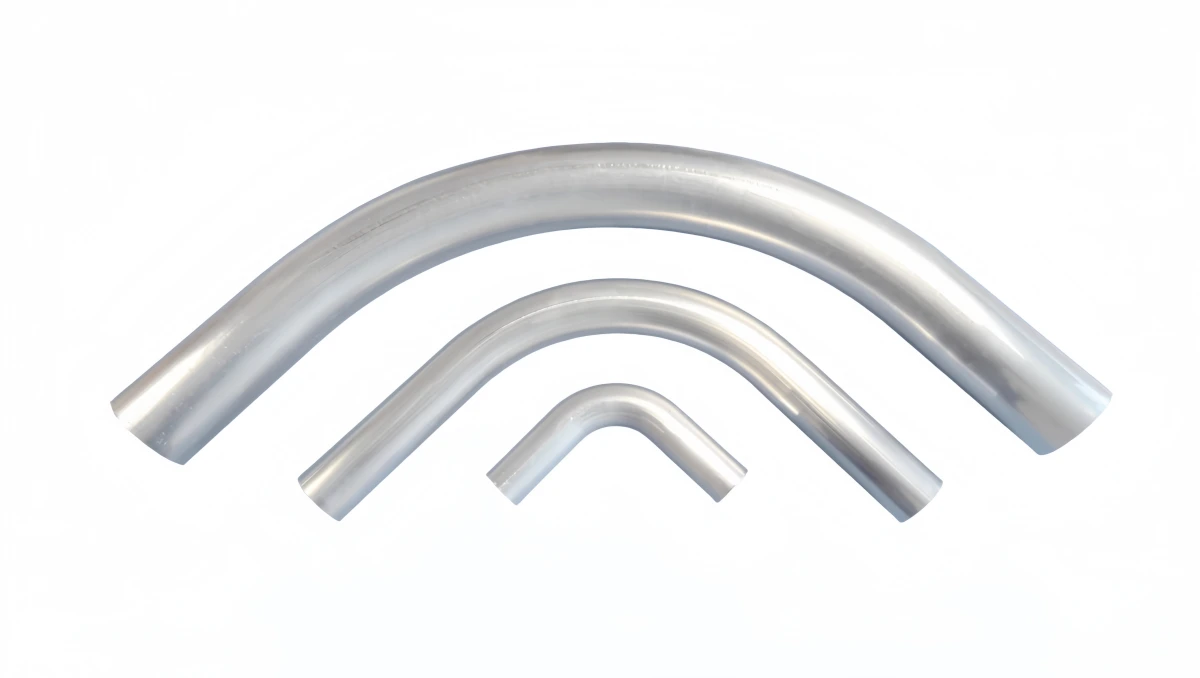

For any high-stakes bending aluminum pipe project, mandrel bending is the premier choice for achieving tight radii and maintaining a perfectly round profile. The process involves inserting a flexible rod (the mandrel) inside the pipe. This rod supports the pipe’s inner wall and prevents it from collapsing. This method is essential for applications where the flow of liquid or air through the pipe is critical. It is a more complex process, but it delivers unmatched quality.

When a design calls for a large, sweeping curve, roll bending is the ideal method. This process uses three rollers to gradually curve the pipe into the desired radius. It is a highly effective technique for large-scale bending aluminum pipe. Roll bending is highly controllable and can produce very consistent curves over long sections of pipe. However, it is not suitable for creating the tight, complex bends that require a different specialty within bending aluminum pipe.

Choosing the right method is a balance of quality, cost, and design requirements.

| Bending Method | Quality of Bend | Best For | Common Issues to Watch For |

| Mandrel Bending | Excelente | Tight radii, thin walls, high-spec parts | Higher cost, slower setup time |

| Curvado de rodillos | Muy buena | Large radii, gentle curves, long sections | Not suitable for tight bends |

| Ram Bending | Fair to Poor | Simple bends, non-critical applications | High risk of kinking/flattening |

Is kinking during fabrication ruining your aluminum pipes? This common problem is frustrating but completely avoidable with the right technique for bending aluminum pipe.

From my experience, the most effective way to prevent kinking is to use an internal support. This can be a flexible mandrel for professional jobs or even tightly packed sand for simpler tasks. This support stops the inner wall from collapsing on itself.

A kink is more than just a cosmetic flaw; it is a structural failure. It creates a weak point that can easily crack. For any purchasing manager, ensuring your supplier has a reliable process to prevent kinking is a critical part of quality control. The key lies in supporting the pipe from the inside during the bending aluminum pipe process. Without this internal support, the compressive forces on the inside of the bend will inevitably cause the pipe wall to buckle and fold. This is a non-negotiable step in our quality assurance process for all bending aluminum pipe orders.

The concept is simple: you must support the pipe’s interior to maintain its shape during any bending aluminum pipe task.

Even with support, you cannot ignore the physical limits of the material when bending aluminum pipe.

Are you trying to complete a project without the right equipment? Using improper tools is a guaranteed way to get poor results when bending aluminum pipe, leading to wasted material.

In our factory, the primary tool for precision work is a CNC mandrel bender. For manual jobs, a high-quality pipe bender that matches the pipe’s diameter, along with a deburring tool and measuring tools, are the absolute essentials.

Having the right tools is the difference between a professional result and a failed attempt. The tool must be designed specifically for the size and type of pipe you are working with. Using a bender designed for a different size or for steel will often damage the softer aluminum. A key part of our service is ensuring we have the correct tooling for each client’s specific project, which is fundamental to successful bending aluminum pipe.

The choice of tools depends entirely on the required precision, volume, and complexity of the bend for your bending aluminum pipe project.

The act of bending aluminum pipe is just one part of the process. Several other tools are necessary for a quality job.

| Tool | Propósito | Why It’s Important for Bending Aluminum Pipe |

| Pipe Cutter | To cut the pipe to the correct length before bending. | Provides a clean, square edge which is necessary for proper tool fit. |

| Deburring Tool | To remove the sharp burrs left after cutting. | Prevents scratching of the bending dies and ensures a safe, smooth finish. |

| Calipers | For precise measurement of diameter and wall thickness. | Confirms the pipe matches specifications before the bending process starts. |

| Protractor | To accurately measure the angle of the bend. | Ensures the final angle from bending aluminum pipe meets design requirements. |

Are you thinking about using a torch to make bending easier? Applying heat incorrectly is one of the fastest ways to destroy the structural integrity of an aluminum pipe.

Based on my two decades of experience, you should almost never use heat for bending aluminum pipe, especially for common structural alloys like 6061-T6. The heat ruins the temper and severely weakens the material. Cold bending with the correct tooling is the professional method.

This is one of the most critical quality control points in aluminum fabrication. Many people assume that since heat makes metal softer, it must make bending easier. For heat-treated aluminum alloys, the specific strength is achieved through a controlled process. Applying uncontrolled heat with a torch reverses this process, returning the metal to a soft, weak state. This is a catastrophic failure for any part that relies on the material’s strength. This is why a proper cold bending aluminum pipe process is so important.

When you heat a T6-tempered aluminum pipe during a bending aluminum pipe attempt, you are performing an uncontrolled annealing process.

There are very few situations where heat is acceptable. It is generally limited to non-heat-treatable alloys.

| Alloy / Temper | Heat Recommended for Bending? | Reason |

| 6061-T6 / 6063-T6 | NO (Critical) | Destroys the T6 temper and dramatically reduces strength. |

| 5052-H32 | No | Can be easily cold-bent; heat is unnecessary and can affect hardness. |

| 3003-H14 | No | Very formable when cold; heat offers no real benefit. |

| Any ‘O’ Temper | Yes, with extreme caution | Material is already annealed. Controlled heat can help with thick walls. |

As the table shows, for the vast majority of common tempers, heat should be avoided. A capable manufacturer relies on the right machinery and techniques for bending aluminum pipe, not on a torch.

Successful bending aluminum pipe relies on a professional process. It requires the right method, proper tools, and a deep respect for the material’s properties to achieve clean, strong, and accurate parts.