Adresse

304 Nord Kardinal

St. Dorchester Center, MA 02124

Arbeitszeiten

Montag bis Freitag: 7AM - 7PM

Am Wochenende: 10AM - 5PM

Adresse

304 Nord Kardinal

St. Dorchester Center, MA 02124

Arbeitszeiten

Montag bis Freitag: 7AM - 7PM

Am Wochenende: 10AM - 5PM

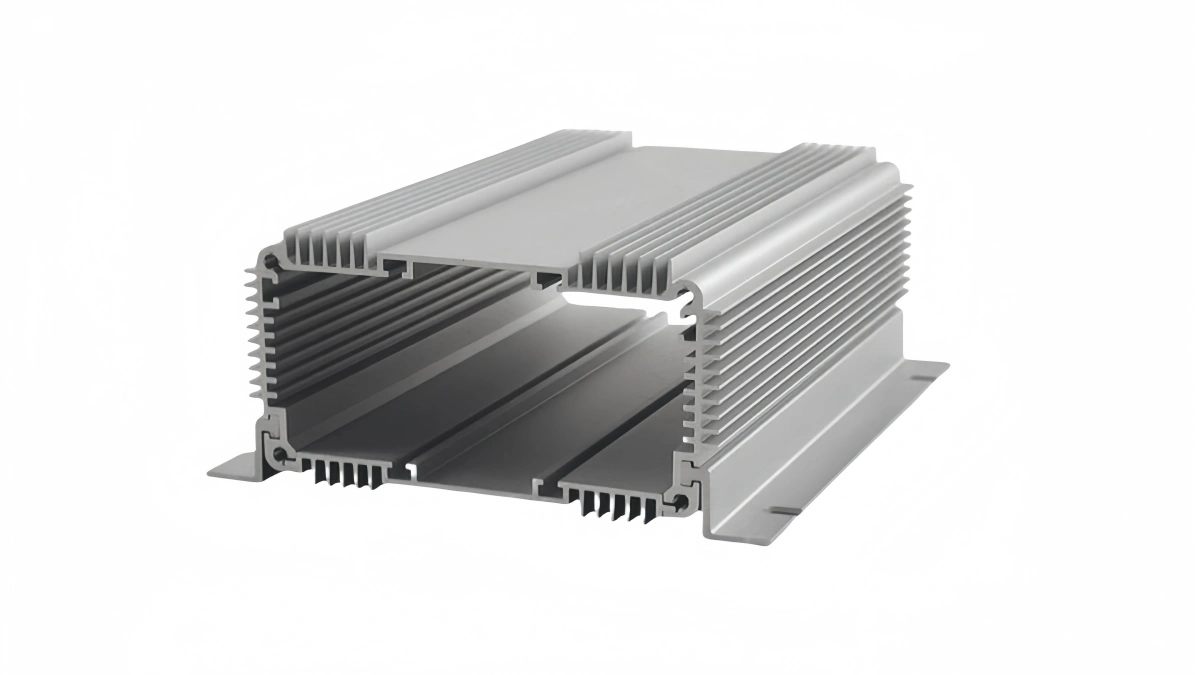

Are you worried about protecting your sensitive electronics? A flimsy case can lead to failure and costly damage. An extruded aluminum enclosure is the powerful and reliable shield your project demands.

In my years of manufacturing experience, I’ve found that an extruded aluminum enclosure is the ultimate choice because it perfectly blends high strength, light weight, and amazing heat dissipation. It offers a premium level of security and performance that other materials simply cannot match for protecting valuable components.

Now, you might be wondering what makes these enclosures so special. Let’s look closely at how they are made, the key benefits you get, and how you can select the perfect one for your specific needs.

Have you ever wondered how a solid piece of metal becomes a complex, hollow shape? The process might seem simple, but if it’s done wrong, you get weak parts. I’ll show you how we ensure it’s done right every time.

I’ve personally overseen this process thousands of times. We take a solid aluminum cylinder, called a billet, heat it to a specific temperature, and then use a powerful hydraulic press to force it through a steel die. This creates a long, perfect profile which we then cut to your exact length.

The extrusion process is a fantastic example of engineering. But to truly understand the quality of the final extruded aluminum enclosure, you need to know the key steps involved. Each step is critical for achieving the strength and precision that your project requires. As a purchasing manager, understanding this process helps you ask the right questions and identify a supplier who truly knows what they are doing.

The journey from a raw aluminum billet to a finished extruded aluminum enclosure involves several carefully controlled stages.

Controlling every step of this process is what separates a high-quality supplier from a low-quality one. For example, if the billet temperature is wrong, the surface finish will be poor. If the extrusion speed is too fast, the profile can crack. We have strict quality control at every stage. This ensures that every extruded aluminum enclosure we deliver has consistent wall thickness, precise dimensions, and the structural integrity needed to protect your products. This attention to detail prevents the very problems—like parts not fitting together—that I know cause major headaches for purchasing managers.

Your products contain valuable and sensitive components. Using a cheap plastic case is a major risk that can lead to failures in the field. An extruded aluminum enclosure provides the superior protection and peace of mind you need.

From my direct experience, the most important benefits are incredible strength, light weight, and natural heat dissipation. Aluminum is also highly resistant to corrosion and provides excellent EMI shielding, making it a reliable, long-term choice for protecting sensitive electronics.

Let’s dive deeper into these benefits. When you choose an extruded aluminum enclosure, you are not just getting a box. You are investing in a set of features that directly improve your product’s performance, reliability, and even its final cost. For a purchasing manager, understanding these benefits helps justify the choice over cheaper, less effective alternatives.

Aluminum is famous for being both strong and light. An extruded aluminum enclosure can withstand significant impacts and vibrations, protecting the delicate circuit boards and components inside. This is crucial for industrial equipment or portable devices that might be dropped or handled roughly. At the same time, its low weight helps reduce shipping costs and makes the final product easier for your customers to handle. This combination is very difficult to find in other materials.

Many electronic components generate a lot of heat. If that heat is not managed properly, it can reduce performance and lead to premature failure. An extruded aluminum enclosure acts as an excellent heat sink. The metal naturally draws heat away from the components and dissipates it into the surrounding air. We can even design the extrusion profile with integrated heat sink fins to make this process even more efficient, eliminating the need for a separate fan or heat sink and saving you assembly time and cost.

Aluminum naturally forms a thin, tough layer of aluminum oxide on its surface. This layer protects the metal from rust and corrosion, even in damp or harsh environments. This means your enclosure will look good and perform well for years. Furthermore, a metal box like an extruded aluminum enclosure creates a Faraday cage. This blocks electromagnetic interference (EMI) from getting in or out, which is essential for many sensitive electronics, especially in communications and medical devices.

Here is a simple breakdown of how these features benefit you:

| Merkmal | Benefit for Your Project |

| Leichtgewicht | Lowers your shipping costs and makes handling easier. |

| Hohe Festigkeit | Protects your components from impact and vibration. |

| Heat Dissipation | Prevents your electronics from overheating and failing. |

| Korrosionsbeständigkeit | Ensures a long product life, even in tough conditions. |

You know that a one-size-fits-all approach rarely works for specialized products. You need an enclosure that fits your design perfectly. Using a generic, off-the-shelf box often leads to compromises in size, function, or appearance.

In my work helping clients, I see many different types. The most common are standard rectangular boxes, U-shaped channels, and multi-piece interlocking enclosures. But the real power is that we can create completely custom profiles based on your drawings, designed to fit your product’s unique shape and needs.

Choosing the right type of extruded aluminum enclosure is a key decision. It affects how your components will fit, how the product is assembled, and its final look and feel. Let’s explore the main options available to you, from standard shapes to fully customized solutions.

Standard profiles are a great starting point for many projects. They are based on common shapes that are versatile and cost-effective. These are often available in stock sizes or can be cut to a specific length quickly. They are perfect for prototypes or applications where a simple, functional housing is all that is needed. An extruded aluminum enclosure of this type is a workhorse for the electronics industry.

This is where an extruded aluminum enclosure truly shines. Instead of trying to fit your design into a standard box, we can create a box that is part of your design. We work from your CAD drawings to create a unique extrusion die. This process allows you to integrate features directly into the enclosure’s profile. For example, you can have internal slots for sliding in a PCB, external fins to act as a heat sink, or special channels for mounting. This level of integration simplifies your assembly process, reduces the number of parts you need to manage, and results in a more professional and streamlined final product. A custom extruded aluminum enclosure shows a high level of design quality.

Here is a look at some common types and where they are used:

| Enclosure Type | Beschreibung | Gemeinsame Anwendungen |

| One-Piece Tubular | A simple, hollow rectangular or square shape. | Power supplies, small project boxes, converter housings. |

| Two-Piece “Clamshell” | Two interlocking halves that slide or snap together. | Test equipment, handheld devices, portable meters. |

| U-Channel | An open-sided profile, often closed with end plates. | Mounting circuit boards, DIN rail components, amplifiers. |

| Custom Profile | Designed specifically to match your product’s shape. | Integrated housings, LED light fixtures, complex machinery. |

Choosing the wrong enclosure can create serious problems. It can lead to production delays, components that don’t fit, and even product failure. Making the right choice from the beginning is critical to avoid these expensive issues.

I always advise my clients to focus on four key areas. First, the size and shape you need. Second, the environment where it will be used. Third, your thermal needs. And fourth, the level of customization you require. Getting these right is the key to success.

Selecting the perfect extruded aluminum enclosure is a methodical process. As a purchasing manager, you need to balance cost, performance, and design requirements. By asking the right questions upfront, you can ensure that the enclosure you source will meet all your specifications and prevent downstream problems. Let’s break down the factors you should consider.

This seems obvious, but it’s easy to get wrong. You need to think about the internal dimensions required to house your components, including the PCB, connectors, and any wiring. Leave enough clearance for assembly and airflow. Also, consider the external dimensions. Will the extruded aluminum enclosure need to fit inside a larger assembly? Make sure to provide your supplier with clear drawings that specify all critical dimensions and tolerances.

Where will your product be used? An enclosure for an indoor office device has very different requirements than one for outdoor industrial machinery. Consider if you need protection from dust or water. This is often defined by an IP (Ingress Protection) rating. If the enclosure will be exposed to chemicals or salt spray, you should also consider a protective surface finish like anodizing or powder coating for your extruded aluminum enclosure.

The extrusion process creates the profile, but most enclosures require more work. Do you need holes drilled for connectors, vents cut for airflow, or threaded holes for screws? This is done through secondary CNC machining. You also need to choose a surface finish. Anodizing provides a hard, corrosion-resistant surface and can be done in different colors. Powder coating offers a durable, decorative finish in a wide range of colors. Planning for these steps early ensures your extruded aluminum enclosure arrives ready for assembly.

This checklist can help guide your decision:

| Consideration | Key Questions to Ask Yourself |

| Size | What are the exact internal dimensions my components need? |

| Environment | Will the enclosure be used indoors, outdoors, or in a harsh setting? |

| Heat | How much heat will my electronics generate, and do I need heat sink fins? |

| Access | How often will I need to open the enclosure for service or assembly? |

| Fertigstellung | Do I need a specific color, a protective coating, or custom graphics? |

Choosing the right extruded aluminum enclosure is a critical decision. With a knowledgeable partner, you get a strong, reliable, and perfectly customized solution to ensure your project’s ultimate success.