Adresse

304 Nord Kardinal

St. Dorchester Center, MA 02124

Arbeitszeiten

Montag bis Freitag: 7AM - 7PM

Am Wochenende: 10AM - 5PM

Adresse

304 Nord Kardinal

St. Dorchester Center, MA 02124

Arbeitszeiten

Montag bis Freitag: 7AM - 7PM

Am Wochenende: 10AM - 5PM

Struggling with standard profiles that just don’t fit your vision? I’ve seen how this limits creativity. But what if you could get the perfect edge, every single time?

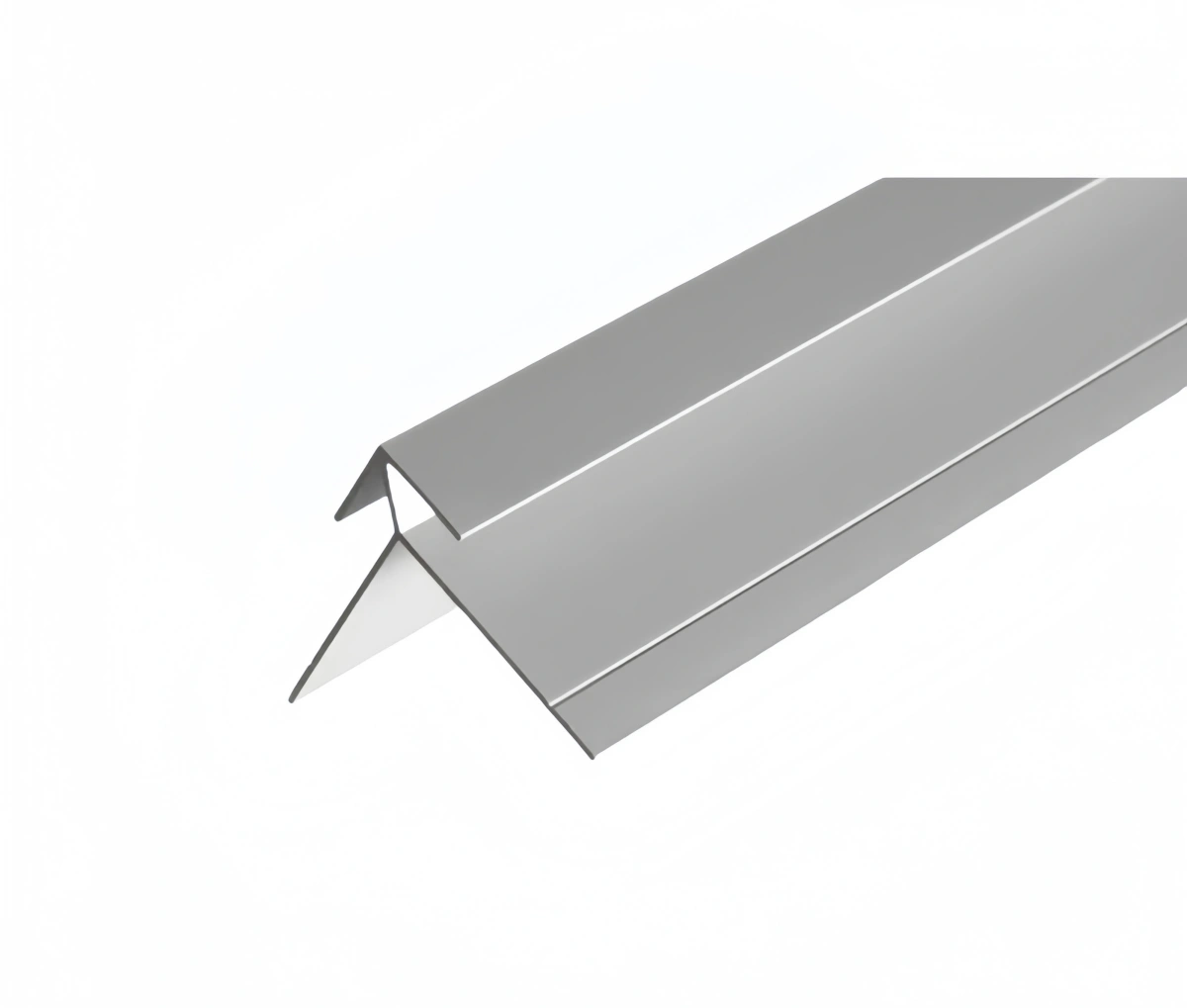

Custom aluminum corner profiles offer unparalleled versatility for architectural and industrial designs. They are specifically engineered to meet precise project requirements, ensuring a perfect fit and finish where generic options fall short, thus enhancing both aesthetics and functionality.

I know you’re looking for solutions that truly match your unique needs. That’s why I want to explore these profiles further with you. Let’s look at what makes them so special and how they can help your projects.

Ever felt unsure about what “custom” really means for aluminum profiles? I understand the confusion. Let’s clear this up and see how it benefits your specific designs directly.

A custom aluminum corner profile is an extruded aluminum shape specifically designed and manufactured to fit unique angles, dimensions, or functional requirements in a project. Unlike standard off-the-shelf profiles, these are tailored to precise specifications provided by the client.

I’ve been in the aluminum business for a long time, and when I talk about custom aluminum corner profiles, I mean profiles that are truly born from your specific needs. It’s not just about picking a slightly different size from a catalog. It’s about us, at ALUT, taking your drawings, your samples, or even just your detailed ideas, and turning them into a physical product. This product integrates seamlessly into your larger assembly. This could be for LED lighting, industrial machines, or architectural elements.

So, what makes it “custom”? I focus on a few key areas with my clients:

As a factory with over 10,000 square meters of space, we have the capability. We manage the entire customization process for custom aluminum corner profiles. When a purchasing manager or product manager from the US or Europe comes to us, I know their needs. They’re looking for more than just a product; they’re looking for a reliable partner. They are often tired of suppliers whose sales reps lack professional knowledge. My team and I ensure we understand your technical requirements from the very start.

Here’s a simplified view of how we approach a custom order for a custom aluminum corner profile:

| Bühne | Our Focus at ALUT | Your Benefit |

| 1. Design Consultation | Understanding your exact needs, drawings, and application for the profile. | Ensures the custom aluminum corner profile is perfectly suited for its purpose. |

| 2. Die Creation | Precision engineering of the extrusion die based on your design. | Guarantees accurate profile shape and dimensions, avoiding future issues. |

| 3. Extrusion & Finishing | Using the right alloy, extruding, and applying the specified surface finish. | You receive a high-quality product meeting all your specifications. |

| 4. Quality Control | Rigorous checks for dimensional tolerances, specifications, and finish quality. | Avoids issues of non-conformance that you might have faced with other suppliers. |

| 5. Logistics Management | Ensuring timely delivery, whether to the US, Canada, or Europe. | Prevents production delays for your downstream customers and projects. |

This commitment to detail is why I believe our custom aluminum corner profiles stand out. We aim to solve your pain points. For example, we ensure dimensional tolerances are met, so you don’t face assembly issues down the line.

Are standard profiles causing design headaches or a less-than-perfect finish? I’ve seen this too often. Let’s explore why going custom can be a game-changer for your projects.

Custom aluminum corner profiles are used to achieve precise fits, unique aesthetics, and specific functionalities that standard profiles cannot offer. They optimize material use, enhance structural integrity, and allow for design innovation, leading to superior end products.

From my experience working with numerous clients, especially purchasing managers in the US and Europe, the decision to use custom aluminum corner profiles is key. These clients value engineering design and quality control highly. The choice often comes down to overcoming the limitations of standard, off-the-shelf options. I’ve seen how the “one-size-fits-all” approach just doesn’t cut it when you’re aiming for excellence in your products.

When you opt for a custom aluminum corner profile, I see several clear benefits emerge:

I often have discussions with clients about when to choose custom over standard solutions. It’s an important consideration. Here’s a simple table I use to illustrate the main differences for a custom aluminum corner profile versus a standard one:

| Merkmal | Standard Profiles | Custom Aluminum Corner Profiles |

| Fit | Approximate, may require adaptation | Precise, designed for the specific application |

| Functionality | Basic, limited by standard designs | Can integrate multiple functions specifically |

| Gestaltungsfreiheit | Restricted by available shapes/sizes | Virtually unlimited design possibilities |

| Material Efficiency | Can be inefficient, using excess material | Optimized for strength and material use |

| Initial Cost | Lower per unit (for common shapes) | Higher die cost, potentially lower overall cost |

| Vorlaufzeit | Shorter (if in stock and no mods needed) | Longer (due to die creation and customization) |

While the initial die cost for a custom aluminum corner profile is a factor, I always encourage my clients to look at the total cost of ownership. Reduced assembly time, fewer components, and improved product quality often mean that custom profiles provide better long-term value. This is especially true for B2B wholesale needs where consistency and quality are paramount. My team at ALUT is here to help you evaluate this. We want to ensure you get a solution that truly benefits your bottom line. We aim to help you avoid those frustrating supplier issues, like poor QC that lead to dimensional tolerance problems or unprofessional communication.

Curious about the magic behind creating a perfectly shaped aluminum profile from scratch? I understand it can seem complex. Let’s demystify the manufacturing process together, step by step.

Custom aluminum corner profiles are primarily made through the aluminum extrusion process. This involves heating an aluminum billet and forcing it through a shaped die. Subsequent steps include cutting, heat treatment (tempering), surface finishing, and fabrication if needed.

As someone who oversees a factory that specializes in customized aluminum products like custom aluminum corner profiles, I can tell you that making them is a precise and fascinating process. It’s not just about pushing metal through a hole. It’s a careful blend of engineering, metallurgy, and skilled craftsmanship. I want to walk you through how we at ALUT bring your designs for a custom aluminum corner profile to life. We ensure the quality control that you, as a purchasing manager or product manager, rightly demand from your suppliers.

The heart of creating any custom aluminum corner profile is the extrusion process. Here’s how I explain it to my clients when they ask:

Making the raw custom aluminum corner profile is just the start. Several other steps are crucial for the final product:

I know that insufficient supplier quality control is a major pain point for many purchasing managers. That’s why, throughout this entire manufacturing process for every custom aluminum corner profile, my team implements rigorous quality checks. From die design review to final inspection of the finished parts, we monitor dimensions, tolerances, surface finish, and material properties. This is how we ensure that the parts you receive from ALUT meet your exact design requirements. This prevents costly assembly problems or product failures on your end. We can provide products made in China. We can also explore options for products made in Vietnam through our network, to help you navigate tariffs and diversify your supply chain.

Feeling limited by the usual L-shapes when you think of corner profiles? I’ve seen many clients surprised by the sheer variety possible. Let’s explore the diverse world of custom aluminum corner profiles together.

Custom aluminum corner profiles exist in countless variations beyond simple L-shapes. Types include unequal leg L-profiles, lipped corners, coved corners, sharp corners, radiused corners, and complex multi-functional profiles with integrated channels, screw ports, or decorative features.

When I talk to purchasing managers and product designers about custom aluminum corner profiles, one of the first things I like to clarify is important. “Custom” means we’re not confined to a pre-set catalog of shapes that you must choose from. While the basic concept is a profile designed for a corner, the actual forms these can take are incredibly varied. They are driven entirely by your specific application and design intent. At ALUT, we’ve produced a vast array of these profiles over the years, each tailored to a unique need.

While every custom profile is unique to the client’s project, I can group them into some general categories. These are based on common design needs I’ve seen for a custom aluminum corner profile:

To give you a better idea of the versatility, here are some common applications for which I’ve supplied custom aluminum corner profiles:

| Application Area | Type of Custom Corner Profile Often Used | Key Benefits Realized by Client |

| LED Lighting Fixtures | L-profiles with channels for LED strips, integrated heat sink features | Secure LED mounting, effective thermal management, clean and modern aesthetics |

| Electronic Enclosures | Lipped or grooved profiles for panel mounting, features for EMI shielding | Easy assembly, secure panel fitting, protection for sensitive internal components |

| Retail Displays & Fixtures | Decorative L-shapes, profiles with slots for signage or shelving supports | Enhanced visual appeal of display, structural support, versatility in design |

| Machinery & Equipment | Robust L-profiles with specific mounting holes, protective edge profiles | Durability in industrial environments, precise component mounting, operator safety |

| Architectural Elements | Sharp or radiused corners, reveal profiles, custom angle L-shapes | Aesthetic precision in building design, unique design features, weather resistance (with appropriate finish) |

| Furniture | Lightweight L-profiles with smooth finishes, integrated connection features | Modern design possibilities, structural integrity, ease of assembly for manufacturers |

As your supplier, my primary goal at ALUT is to understand your exact needs for any custom aluminum corner profile. Whether you’re importing parts for assembly into LED lights, consumer appliances, or industrial machines, we can create the profile that fits perfectly. We place a strong emphasis on quality control and proactive project management. This helps avoid those common supplier frustrations like unprofessional responses, unexpected quality issues, or delayed delivery. We are comfortable working from your detailed drawings or samples. We ensure the final product, whether it’s made in China or potentially through our contacts in Vietnam, meets your company’s high standards.

I trust this gives you a clearer view of custom aluminum corner profiles and their potential. My team at ALUT and I are ready to help you achieve the perfect fit and function for your projects.