Adresse

304 Nord Kardinal

St. Dorchester Center, MA 02124

Arbeitszeiten

Montag bis Freitag: 7AM - 7PM

Am Wochenende: 10AM - 5PM

Adresse

304 Nord Kardinal

St. Dorchester Center, MA 02124

Arbeitszeiten

Montag bis Freitag: 7AM - 7PM

Am Wochenende: 10AM - 5PM

Struggling with heavy, cumbersome materials for your builds? Feeling frustrated by complex assembly processes? I’ve discovered that aluminum structural profiles offer incredible versatility and strength, simplifying many challenges.

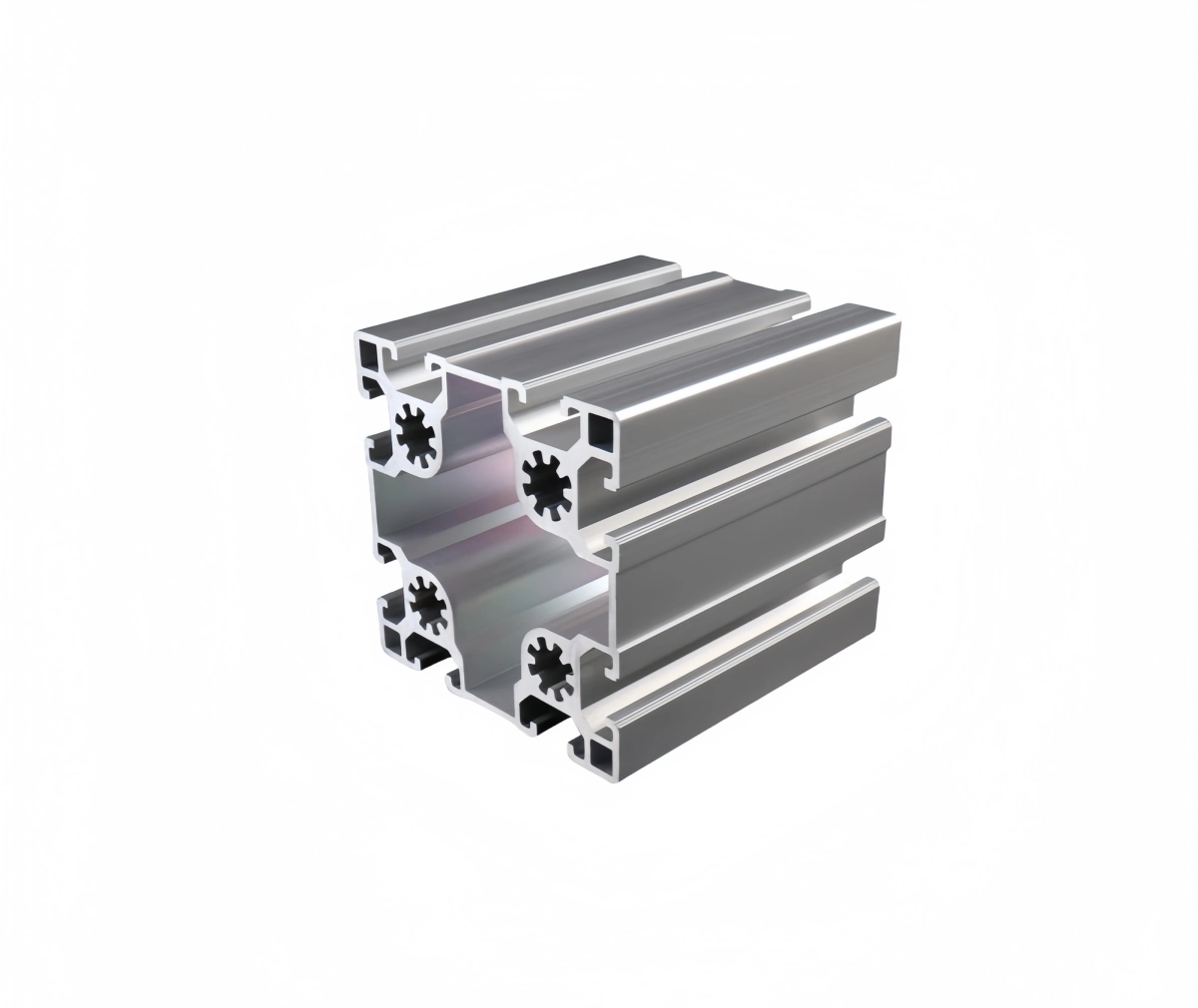

From my extensive experience in the aluminum industry, I can confidently say that aluminum structural profiles are a superb choice. These are precisely engineered extruded aluminum shapes, designed for construction and framing. They deliver an outstanding mix of lightness, robustness, and corrosion resistance, making projects using aluminum structural profiles both easier to manage and more durable.

You might be wondering what makes these aluminum structural profiles so effective and how they can benefit your specific applications. Let’s dive deeper into the world of these remarkable components.

Unsure what “structural profiles” truly means in this context? Confused by technical jargon when you just need clear, straightforward answers about aluminum structural profiles? I’m here to break it down simply for you.

In my work, I’ve learned that aluminum structural profiles are essentially custom-designed aluminum extrusions. They are manufactured in various cross-sectional shapes, such as T-slots, V-slots, or square tubes. These forms aren’t arbitrary; they are specifically engineered to provide structural support and enable easy connection and assembly.

To truly understand these specialized extrusions, it’s helpful to first grasp the basics of aluminum extrusion. This is a manufacturing process where aluminum alloy material is pushed through a die with a specific cross-sectional profile. Imagine squeezing toothpaste from a tube – the shape of the opening determines the shape of the toothpaste stream. Similarly, the die shapes the aluminum into long pieces with consistent cross-sections. The “structural” aspect means these aluminum structural profiles are designed to bear loads and form the skeletons or frameworks of various constructions, from machine guards to entire building facades.

The choice of aluminum alloy is crucial for the performance of aluminum structural profiles. Different alloys offer varying balances of strength, extrudability, and corrosion resistance. The most common alloys I see used are from the 6xxx series, particularly 6061 and 6063.

| Legierung | Key Properties | Typical Uses for these Profiles |

| 6061 | Good strength, weldability, corrosion resistance | Load-bearing structures, machine frames |

| 6063 | Excellent extrudability, good surface finish | Architectural applications, window frames |

| 6005A | Medium strength, good extrudability | Complex profiles, transportation |

These aluminum structural profiles can be standard, off-the-shelf designs, or they can be completely custom-made to fit unique project requirements. This is where a supplier like ALUT, with strong engineering and manufacturing capabilities, becomes invaluable. The specific shape or “profile” directly contributes to its function. For example, T-slot profiles feature T-shaped grooves along their lengths. These grooves allow special nuts and bolts to slide in and lock at any position, enabling highly modular and adjustable constructions. You can easily attach other profiles, panels, or accessories without welding or complex machining.

When compared to other traditional structural materials like steel or wood, aluminum profiles offer distinct advantages. Steel is undeniably strong, but it’s also very heavy. Wood is lighter but can be susceptible to moisture and pests. Aluminum, on the other hand, provides an excellent strength-to-weight ratio. It’s significantly lighter than steel, making handling, transportation, and installation easier and often cheaper. Plus, aluminum naturally forms a protective oxide layer, giving it superior corrosion resistance, especially important for outdoor or humid environments. This combination of features makes aluminum structural profiles a go-to solution in modern engineering and design.

Do you think these aluminum structural profiles are only suitable for small, lightweight DIY projects? Are you perhaps underestimating their potential for more demanding industrial and architectural applications? I’ve personally seen them utilized in an incredibly diverse range of robust and complex systems.

Throughout my years in the aluminum sector, I’ve witnessed aluminum structural profiles being adopted across a vast spectrum of industries. Their applications are incredibly broad, covering everything from the frames of heavy machinery and intricate automation lines in factories, to sophisticated architectural elements like window frames and curtain wall systems. You’ll also find them in retail displays, solar panel mounting structures, and custom enclosures.

The versatility of these aluminum structural profiles is one of their most compelling attributes. Let’s explore some key application areas in more detail.

In the industrial world, efficiency, adaptability, and durability are paramount. These aluminum extrusions excel here.

The aesthetic appeal, combined with durability and low maintenance, makes these profiles a favorite in construction.

Beyond these major sectors, these aluminum components are found in:

The reason these extrusions are so widely adopted is due to their inherent benefits: modularity allows for easy design changes, lightness reduces installation effort, and corrosion resistance ensures longevity, particularly in outdoor or challenging environments. The use of aluminum structural profiles significantly contributes to operational efficiency and design flexibility in many of these applications.

Feeling overwhelmed by the sheer variety of “types” of aluminum structural profiles you encounter online or in catalogs? Are you concerned you might select a profile that isn’t quite right for your specific needs? I can clarify the common categories to help you navigate the options.

From my experience handling countless projects, I’ve found that we can generally categorize aluminum structural profiles based on their cross-sectional shape and intended connection system. The most prevalent types I work with include T-slot profiles, V-slot profiles, standard square or rectangular tubes, and various angled or channel profiles. Each of these types offers unique connection methods and distinct structural characteristics tailored for different purposes.

Understanding these different types of aluminum structural profiles is key to selecting the right profile for your project. Let’s break them down.

These are perhaps the most widely recognized type, especially for modular constructions. T-slot profiles feature one or more T-shaped grooves running along their lengths. These grooves are designed to accept specialized T-nuts, which can slide along the slot and be tightened at any point to secure connecting elements, brackets, or other profiles. This system allows for incredible flexibility in assembly and modification without needing to drill or weld. T-slot aluminum structural profiles come in various series (e.g., 20-series, 30-series, 40-series, 45-series), where the number usually refers to the metric dimension of the profile’s basic width (e.g., 20mm, 40mm).

V-slot profiles are similar to T-slots but incorporate V-shaped grooves on their faces. These V-grooves are specifically designed to act as linear rails for V-wheels. This makes V-slot profiles ideal for applications requiring smooth and precise linear motion.

These are simpler, hollow profiles without the specialized slots of T-slot or V-slot systems. They offer good all-around strength and are often used for general structural purposes where high modularity isn’t the primary concern. Connection usually involves welding, bolting through drilled holes, or using internal connectors.

Angle profiles (L-shapes) and channel profiles (U-shapes or C-shapes) are basic structural elements used for bracing, edging, mounting, or forming simpler frames. They are versatile and can be combined with other profile types.

Here’s a quick comparison of different profile types:

| Profil Typ | Hauptmerkmal | Allgemeiner Anwendungsfall |

| T-Slot Profiles | High modularity, easy T-nut connections | Machine frames, automation, workstations |

| V-Slot Profiles | V-grooves for linear motion with V-wheels | 3D printers, CNC routers, linear guides |

| Square/Rectangular Tubes | General strength, simpler design | Basic frameworks, structural supports |

| Angle/Channel Profiles | Basic shapes for bracing, edging, support | Brackets, simple frames, reinforcements |

Beyond these standard types, there’s also the vast world of custom aluminum structural profiles. At ALUT, we frequently collaborate with clients who have unique design requirements that off-the-shelf profiles can’t meet. We can design and manufacture dies to produce profiles with virtually any cross-sectional shape, tailored to specific functional or aesthetic needs. Choosing the right type of aluminum structural profile depends heavily on the load requirements, the need for adjustability, the type of connections desired, and the overall application.

Is there a lingering doubt that aluminum, being so lightweight, might not be truly “strong” enough for your needs? Are you questioning if it can handle the demanding structural requirements of your project? I can assure you, when aluminum structural profiles are properly selected and designed, their strength-to-weight ratio is truly impressive.

From my professional standpoint as a supplier of these materials, the strength of aluminum structural profiles is quite remarkable, especially when you consider their low density. While it’s true that, volume for volume, steel generally offers higher absolute tensile strength, aluminum’s excellent strength-to-weight ratio means it can support significant loads effectively. The specific aluminum alloy used and the geometric design of the profile itself are critical factors influencing this strength.

The concept of strength-to-weight ratio is key here. An aluminum profile might weigh only a third as much as a steel profile of similar dimensions, yet it can still provide ample strength for many structural applications. This weight saving translates into easier handling, reduced transportation costs, and often less substantial supporting structures.

Several elements determine how strong an aluminum extrusion will be:

Here’s a simplified look at how some common alloys and tempers compare for these profiles:

| Alloy & Temper | Approximate Yield Strength (MPa) | Approximate Tensile Strength (MPa) | Anmerkungen |

| 6063-T5 | 145 | 186 | Good for complex shapes, moderate strength |

| 6061-T6 | 241 | 262 | Excellent strength, common for structural |

| 6005A-T5 | 200 | 260 | Good balance of strength and extrudability |

While steel boasts higher absolute strength figures, it’s important to consider the application. For many structures, the incredible strength of steel is overkill, and the weight penalty is significant. Aluminum structural profiles can achieve comparable structural integrity for the intended loads with significantly less material weight. This is evident in large machine frames that withstand constant vibrations and in complex architectural structures exposed to various environmental forces.

In summary, aluminum structural profiles deliver exceptional versatility, impressive strength-to-weight, and remarkable ease of use for a wide array of projects. Definitely consider aluminum structural profiles for your next innovative build!