Adresse

304 Nord Kardinal

St. Dorchester Center, MA 02124

Arbeitszeiten

Montag bis Freitag: 7AM - 7PM

Am Wochenende: 10AM - 5PM

Adresse

304 Nord Kardinal

St. Dorchester Center, MA 02124

Arbeitszeiten

Montag bis Freitag: 7AM - 7PM

Am Wochenende: 10AM - 5PM

Are you struggling to find the right partner for your custom aluminum extrusion companies needs? I understand how frustrating it can be when suppliers miss the mark on quality or communication. This crucial decision can truly make or break your project, so let’s navigate this together.

I often see companies facing delays and quality issues due to poor supplier choices. Selecting a reliable custom aluminum extrusion company is essential for maintaining your production schedule and ensuring product integrity, impacting your bottom line.

Don’t let these common pitfalls derail your progress. Continue reading to discover how to avoid these issues and make an informed choice that benefits your business.

Do you know all the services a good extrusion partner can provide? I’ve seen many clients unaware of the full scope, missing out on valuable support that could streamline their operations.

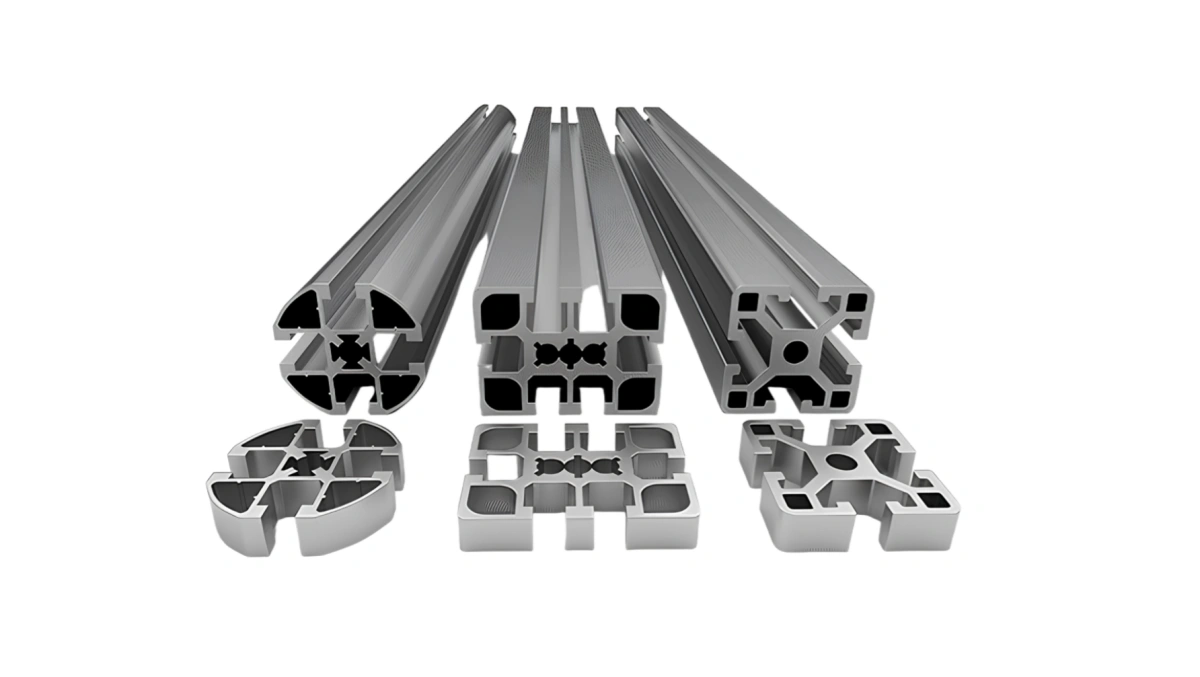

A good custom aluminum extrusion companies offers more than just shaping metal. They provide design assistance, material selection, advanced prototyping, and quality control, ensuring your project meets precise specifications.

Die meisten custom aluminum extrusion companies offers a range of services designed to support you from concept to final product. These services go beyond just pushing metal through a die. They start with the initial design phase. Many companies have engineers who can help you refine your product design. This means they can look at your drawings or samples and suggest improvements. They might recommend changes to make the extrusion process easier. They might also suggest changes to make your product stronger or more cost-effective. This kind of early involvement can save a lot of time and money later on.

After design, material selection is another key service from a custom aluminum extrusion companies. Aluminum comes in many different alloys, each with specific properties. Some alloys are stronger, some are more corrosion-resistant, and some are easier to machine. An experienced company will guide you in choosing the best alloy for your specific application. For example, if you need a part for a marine environment, they will suggest an alloy that resists saltwater damage. If you need a lightweight but strong part, they will recommend an alloy suitable for that.

Prototyping is also a common service from a custom aluminum extrusion companies. Before full production, you often need a prototype to test the fit and function of your design. Custom aluminum extrusion companies can create prototypes quickly. This allows you to check for any issues and make adjustments before committing to a large order. This step is crucial for complex parts or new product development. It reduces the risk of errors in mass production.

Here is a table showing common services:

| Service Category | Examples of Services Offered |

| Design & Engineering | Design review, CAD support, alloy selection guidance |

| Extrusion & Fabrication | Custom profiles, cutting, drilling, bending, welding |

| Finishing & Treatment | Anodizing, powder coating, polishing, painting |

| Qualitätskontrolle | Dimensional inspection, material testing, supply chain management |

| Logistik | Packaging, shipping, global distribution |

Beyond these, many companies, like mine at ALUT, also provide comprehensive supply chain services. This means we manage the entire process from order placement to delivery. This includes quality control throughout manufacturing and managing all the logistics. We ensure the product meets your specifications and arrives on time. This integrated approach simplifies the process for you. It reduces the need to manage multiple vendors. We are a reliable custom aluminum extrusion company.

Have you ever picked a supplier only to regret it later? I’ve seen firsthand how a wrong choice leads to endless headaches and costly delays. It makes you wonder, what truly matters when making this critical decision about a custom aluminum extrusion companies?

Choosing the right custom aluminum extrusion company involves looking beyond just price. You need to assess their engineering expertise, quality control systems, project management capabilities, and communication effectiveness to ensure a successful partnership.

Selecting the right custom aluminum extrusion companies is a crucial step for your project’s success. It requires a careful evaluation of several factors. First, consider their engineering and design capabilities. Do they have experienced engineers who can understand your specific needs? Can they provide valuable input on design for manufacturability? Look for a custom aluminum extrusion companies that can work with your drawings or even develop designs based on your samples. Their ability to offer technical advice can be a huge asset, especially for complex parts.

Second, evaluate their quality control processes. This is paramount. Ask about their quality inspection procedures. Do they perform dimensional checks throughout the production process? How do they ensure material specifications are met? A good custom aluminum extrusion companies will have clear quality management systems in place. They should be able to provide reports and certifications. For us at ALUT, quality inspection is a core part of our service. We ensure product dimensional tolerances and specifications always meet your design requirements.

Third, assess their project management skills. This is vital for on-time delivery. A capable custom aluminum extrusion companies will have a clear system for tracking your order. They should provide regular updates. They should also be proactive in identifying and resolving potential issues. Delays in delivery can stop your production, causing significant losses. Look for a supplier that can demonstrate strong project management, minimizing risks of delays.

Fourth, consider their communication style and responsiveness. Do they provide professional and concise replies to your inquiries? Do their sales representatives have sufficient technical knowledge? Poor communication can lead to misunderstandings and errors. You need a partner who can clearly understand your requirements and communicate effectively. As purchasing managers often dislike unnecessary details, a professional and concise communication style is key when working with a custom aluminum extrusion companies.

Fifth, review their manufacturing capabilities and capacity. Can they handle the volume of your order? Do they have the right equipment for your specific extrusion profile? For example, ALUT has a factory in China with over 10,000 square meters. This large capacity allows us to manage substantial orders efficiently. We operate as a dedicated custom aluminum extrusion companies.

Here is a comparison table for evaluating potential suppliers:

| Evaluation Factor | What to Look For | Warum es wichtig ist |

| Engineering Expertise | Design review, DFM suggestions, CAD support | Ensures product is manufacturable and optimized |

| Qualitätskontrolle | Inspection procedures, certifications, material testing | Prevents product defects, ensures specifications are met |

| Project Management | Order tracking, regular updates, problem-solving | Guarantees on-time delivery, avoids production delays |

| Kommunikation | Professional, concise, knowledgeable sales team | Prevents misunderstandings, streamlines problem-solving |

| Manufacturing Capacity | Factory size, equipment, ability to scale | Ensures order volume can be met, supports growth |

| Supply Chain Services | Logistics, customs, global shipping experience | Reduces complexity, manages tariffs, ensures smooth delivery |

Have you ever wondered why so many industries choose custom aluminum extrusions? I see businesses constantly looking for ways to get a competitive edge. The answer often lies in the unique advantages these custom parts offer. A custom aluminum extrusion companies can explain these benefits.

Custom aluminum extrusions provide unmatched design flexibility, allowing for complex and precise shapes tailored to specific needs. They offer excellent strength-to-weight ratios, corrosion resistance, and cost-effectiveness, making them ideal for diverse applications across many sectors.

Custom aluminum extrusions offer many benefits that make them a popular choice for various industries. One of the main advantages is their incredible design flexibility. Aluminum can be extruded into almost any shape imaginable. This allows engineers to create complex profiles that precisely meet their product’s functional and aesthetic requirements. Unlike other manufacturing methods, extrusion can integrate features like screw ports, heat sinks, or mounting brackets directly into the profile. This reduces the need for secondary machining, simplifying assembly and cutting costs. For example, if you need a specific enclosure for an electronic device, custom extrusion allows you to design a perfect fit. This ensures optimal protection and heat dissipation. A good custom aluminum extrusion companies makes this possible.

Another significant benefit is the excellent strength-to-weight ratio of aluminum. Aluminum is much lighter than steel but still offers considerable strength. This characteristic is crucial in industries where weight reduction is vital. Consider the automotive or aerospace industries. Lighter components mean better fuel efficiency and reduced emissions. In consumer products, lighter parts make items easier to handle and transport. This balance of strength and lightness helps in creating durable yet efficient products. This is a core offering from a custom aluminum extrusion companies.

Corrosion resistance is also a key advantage. Aluminum naturally forms a passive oxide layer when exposed to air. This layer protects the metal from rust and further corrosion. This makes aluminum extrusions suitable for outdoor applications or environments with high humidity or chemical exposure. Anodizing or powder coating can further enhance this resistance. This extends the product’s lifespan and reduces maintenance needs. For instance, in marine applications or outdoor lighting fixtures, this resistance is indispensable. This benefit is something any custom aluminum extrusion company will highlight.

Here are some core benefits summarized:

| Nutzen Sie | Beschreibung | Impact on Product/Project |

| Flexibilität bei der Gestaltung | Create complex, custom cross-sections with integrated features | Allows for innovative designs, reduces part count, simplifies assembly |

| Kraft/Gewicht | High strength with low density | Improves fuel efficiency (automotive), easier handling (consumer goods) |

| Korrosionsbeständigkeit | Natural oxide layer protects against rust; enhanced by finishes | Increases product lifespan, reduces maintenance, suitable for harsh environments |

| Kosten-Wirksamkeit | Lower unit cost for complex profiles, reduced assembly needs | Optimizes production costs, enhances profitability, efficient for volume |

| Wärmeleitfähigkeit | Excellent heat transfer properties | Critical for electronics cooling, LED lighting applications |

Furthermore, aluminum’s excellent thermal conductivity makes it ideal for heat management applications. This is why it is commonly used for heat sinks in electronics and LED lighting. The metal efficiently dissipates heat, preventing overheating and extending the life of electronic components. The recyclability of aluminum also adds an environmental benefit. It can be recycled repeatedly without losing its properties. This supports sustainable manufacturing practices. These combined benefits truly make custom aluminum extrusions a versatile and valuable solution for many product needs, a message reinforced by any good custom aluminum extrusion companies.

Have you ever looked around and realized how many things are made from custom aluminum extrusions? I certainly have. It’s fascinating how widely this material is adopted across seemingly unrelated sectors. It makes you wonder what industries truly rely on them and the custom aluminum extrusion company that provides them.

Custom aluminum extrusions are vital across a vast array of industries due to their versatility and unique properties. They are extensively used in construction, automotive, electronics, aerospace, and consumer goods, offering tailored solutions for specific functional and aesthetic demands.

Custom aluminum extrusions find their way into a surprising number of industries. Their unique properties, such as being lightweight, strong, corrosion-resistant, and highly customizable, make them indispensable. Every custom aluminum extrusion company serves diverse markets.

Die construction industry is a major user. Custom extrusions are used for window frames, door frames, curtain walls, and structural components. Their ability to form complex shapes allows for intricate architectural designs. Their durability means buildings last longer with less maintenance. They are also used in solar panel frames and supports. This helps in the growing renewable energy sector. A custom aluminum extrusion company plays a role here.

Die automotive industry relies heavily on aluminum extrusions. Car manufacturers use them for chassis components, engine parts, and body structures. The lightweight nature of aluminum helps reduce vehicle weight, improving fuel efficiency and reducing emissions. This is critical for meeting modern environmental standards. Custom shapes allow for complex safety features and aerodynamic designs. Many choose a custom aluminum extrusion company for these parts.

In the electronics industry, aluminum extrusions are essential for heat sinks, enclosures, and casings. As electronic devices become more powerful and compact, effective heat dissipation is crucial. Aluminum’s excellent thermal conductivity ensures components stay cool. Custom enclosures protect sensitive electronics while also providing aesthetic appeal. Examples include laptop casings, server racks, and LED lighting fixtures. A specialized custom aluminum extrusion company caters to this need.

Die aerospace industry benefits from aluminum’s high strength-to-weight ratio. Aircraft components, such as fuselage sections, wing parts, and interior structures, often use custom aluminum extrusions. Every kilogram saved in an aircraft translates to significant fuel savings and increased payload capacity. Precision engineering is also critical in aerospace, and aluminum extrusions can meet very tight tolerances. This industry heavily relies on a skilled custom aluminum extrusion companies.

Die consumer goods sector also widely uses custom aluminum extrusions. Products like furniture, sports equipment, and household appliances benefit from their versatility and appearance. For example, bicycle frames, tent poles, and camera tripods often feature custom aluminum profiles. The ability to create sleek, modern designs with various finishes makes aluminum a preferred material. Any good custom aluminum extrusion company can help design these.

Other notable industries include:

Each industry leverages the customizability of aluminum extrusions to solve specific challenges. From creating a lightweight frame for a drone to a sturdy, weather-resistant window frame for a skyscraper, custom aluminum extrusions provide tailored solutions that are both functional and cost-effective. A competent custom aluminum extrusion company is a partner in these innovations.

Choosing the right custom aluminum extrusion company is a pivotal decision for your project’s success. By focusing on expertise, quality, and communication, you can ensure a smooth process and high-quality results.

##About my business

Name: Wilson Yau

E-Mail: [email protected]

Website: https://www.lt-aluminum.com

Brand name: ALUT

Country: China

Products: customized aluminum products

Business model: B2B, wholesale only. We are our factory with an area of more than 10,000 square meters, with factories in China. Customers place orders with us, and our service team provides complete supply chain services, including order management, quality control, and logistics management.

Current operations: Headquartered in China, China (200 employees).

Main export countries: United States, Canada,Europe

Potential customer profile: Buyers or executives of large companies, purchasing managers, or product managers of manufacturers.

Product features: Made in Vietnam or Made in China, standard products can be provided or customized according to drawings or samples provided by customers.

Marketing channels: website, Alibaba, LinkedIn

Our services: supplier procurement, supplier audit, contract manufacturing, process control, quality