Adresse

304 Nord Kardinal

St. Dorchester Center, MA 02124

Arbeitszeiten

Montag bis Freitag: 7AM - 7PM

Am Wochenende: 10AM - 5PM

Adresse

304 Nord Kardinal

St. Dorchester Center, MA 02124

Arbeitszeiten

Montag bis Freitag: 7AM - 7PM

Am Wochenende: 10AM - 5PM

Are you tired of parts that weigh too much or corrode too quickly? I’ve seen many clients struggle with these issues, impacting their final product’s performance and costs.

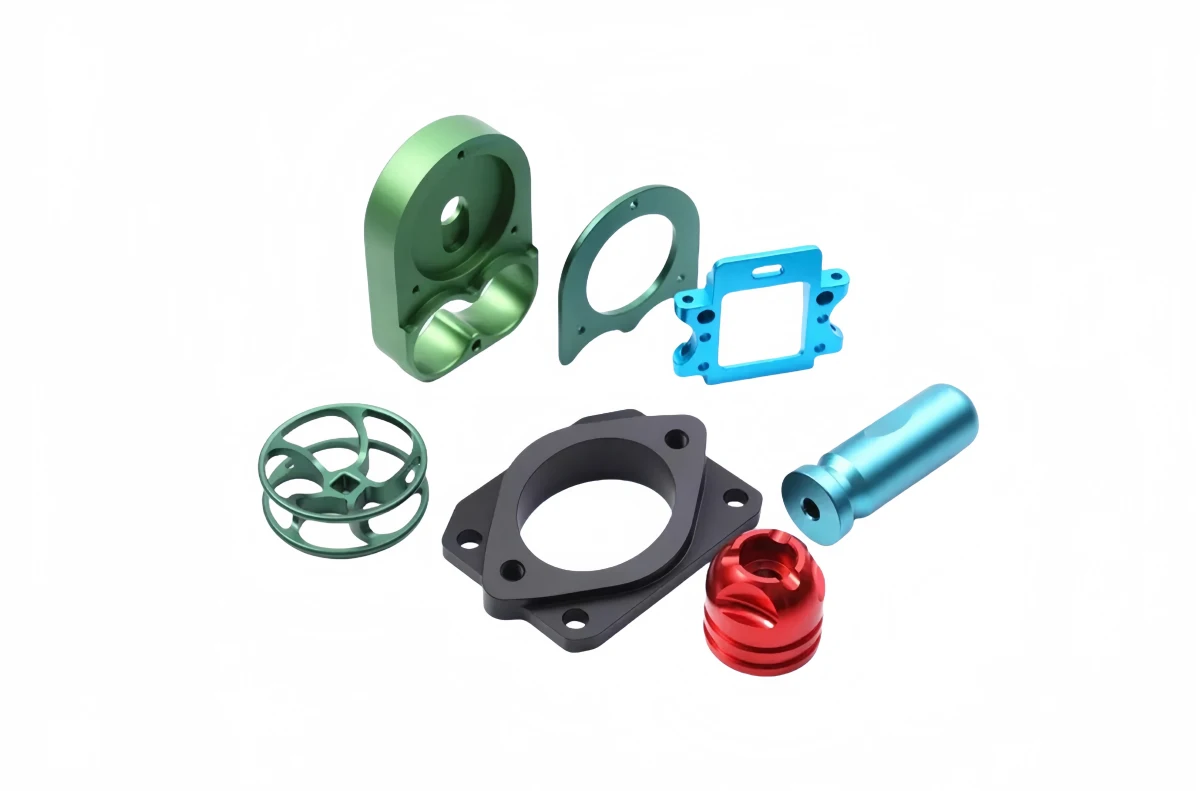

Aluminum parts offer a fantastic solution due to their light weight, excellent corrosion resistance, and high strength-to-weight ratio. These qualities make them ideal for various applications, enhancing product efficiency and longevity while often reducing overall project costs when sourced effectively.

I understand that finding the right material and a reliable supplier is crucial. Let’s explore why aluminum parts might be the perfect fit for your needs and how we, at ALUT, ensure you get the best quality and service.

Are you wondering if switching to aluminum parts is worth it? I often speak with purchasing managers who are looking for an edge, and the benefits of aluminum are compelling.

The key benefits of using aluminum parts include their remarkable lightness, superior corrosion resistance, excellent thermal and electrical conductivity, and high recyclability. These factors contribute to more efficient, durable, and sustainable products, which I’ve seen make a real difference for my clients.

When I talk to clients, especially purchasing managers from the US and Europe, they often look for more than just a low price. They need parts that perform reliably and add value to their products, like LED lighting systems or industrial machines. That’s where the inherent qualities of aluminum parts truly shine.

One of the most significant advantages I always highlight is how light aluminum is. Aluminum is about one-third the weight of steel. This might not sound like much, but imagine this in an automotive application or in portable electronic devices. Less weight means better fuel efficiency or easier handling. For many of my clients who manufacture complex assemblies, reducing the weight of individual aluminum parts can lead to substantial overall weight savings. This directly impacts shipping costs and the ease of installation for their end-users.

Another point I stress is aluminum’s natural ability to resist corrosion. When aluminum is exposed to air, it forms a thin, protective layer of aluminum oxide on its surface. This layer is very durable and prevents the metal from rusting or degrading, even in moist or chemically aggressive environments. This is a huge benefit for products used outdoors or in industrial settings. You don’t have to worry about constant maintenance or replacement of corroded aluminum parts, which saves money and headaches in the long run. I’ve supplied aluminum parts for marine applications where this quality is absolutely critical.

While aluminum is light, it doesn’t mean it’s weak. Many aluminum alloys can be very strong. When we talk about the strength-to-weight ratio, aluminum parts often outperform other materials. This means you can design parts that are both light and robust enough for demanding applications. For businesses importing aluminum CNC parts to assemble into their own products, this means they can achieve structural integrity without adding unnecessary bulk.

I also like to point out a few other benefits:

Here’s a simple comparison I often share:

| Merkmal | Aluminum Parts | Steel Parts (Typical) |

| Dichte | Low (Lightweight) | High (Heavy) |

| Korrosionsbeständigkeit | Ausgezeichnet | Poor to Moderate (can rust) |

| Bearbeitbarkeit | Good to Excellent | Angemessen bis gut |

| Leitfähigkeit | High (Thermal & Electrical) | Mäßig |

| Wiederverwertbarkeit | Ausgezeichnet | Gut |

Choosing the right aluminum parts can directly address concerns about product durability and performance. We focus on providing quality that meets these expectations.

You might be asking, “Is my industry one that typically relies on aluminum parts?” I’ve worked with diverse sectors, and it’s always interesting to see the varied applications.

Aluminum parts are extensively used in the aerospace, automotive, construction, electronics, and consumer goods industries. Their unique combination of light weight, strength, and corrosion resistance makes them indispensable for manufacturing everything from aircraft components and car bodies to window frames and smartphone casings.

From my experience as a B2B supplier of customized aluminum products, I’ve seen firsthand how versatile these components are. Many of our clients in the United States and Europe are purchasing managers or product managers who need reliable parts for their specific industry needs. The demand for high-quality aluminum parts continues to grow.

These are two big ones. In aerospace, every gram matters. The lightweight nature of aluminum parts helps improve fuel efficiency and performance. Think about aircraft fuselages, wings, and interior components. Similarly, the automotive industry uses aluminum parts to reduce vehicle weight, which also improves fuel economy and handling. Engine blocks, chassis components, and body panels are often made from aluminum. I’ve supplied many CNC machined aluminum parts that go into these critical applications, where precision and material integrity are paramount.

In construction, aluminum parts are popular for window frames, door frames, roofing, and curtain wall systems. Why? Because aluminum is durable, resistant to weather, and requires little maintenance. Plus, it can be easily extruded into complex shapes, allowing for modern architectural designs. I’ve seen our extruded aluminum profiles become integral parts of impressive buildings.

Look around you. Your smartphone, laptop, or TV likely contains aluminum parts. Casings, heat sinks, and internal frames often use aluminum because it’s light, looks good, and helps dissipate heat. In the LED lighting industry, which many of our customers are in, aluminum is crucial for heat management to ensure the longevity of the LEDs. The same goes for many electric appliances and industrial machines. The ability to provide custom aluminum products means we can cater to very specific design requirements in this fast-moving sector.

The widespread use of aluminum parts across these sectors underscores their adaptability. As a factory with an extensive area and a dedicated service team, we are equipped to handle orders for customized aluminum products for almost any industry. We focus on providing complete supply chain services, ensuring that the aluminum parts you receive meet your exact specifications. This is essential, as I know delays or quality issues can cause significant problems, like production stoppages for your downstream customers.

“How do these versatile aluminum parts actually get made?” That’s a great question I often get, especially from purchasing managers looking to understand the capabilities of their suppliers.

Aluminum parts are typically manufactured through processes like extrusion, casting (die casting, sand casting), CNC machining, forging, and sheet metal fabrication. The choice of method depends on the part’s complexity, required strength, quantity, and cost considerations, which we always discuss with our clients.

As a factory based in China, with capabilities to also produce in Vietnam, we at ALUT specialize in customized aluminum products. This means we are deeply familiar with these manufacturing methods. Understanding them helps our clients, who are often purchasing managers or product managers, make informed decisions. They value our engineering design input and project management, especially when it comes to selecting the optimal manufacturing process for their aluminum parts.

Let me break down some of the common methods we use:

This is like squeezing toothpaste from a tube. Heated aluminum billet is forced through a shaped die to create long profiles with a consistent cross-section.

This involves pouring molten aluminum into a mold and letting it solidify.

Computer Numerical Control (CNC) machining involves using computer-controlled machines to remove material from a solid block or a pre-formed aluminum part (like an extrusion or casting) to achieve the final shape.

Aluminum is shaped by localized compressive forces, often using a hammer or a press.

This involves cutting, bending, and assembling aluminum sheets to create parts.

Here’s a quick overview of which process might suit different needs:

| Manufacturing Process | Komplexität | Band | Stärke | Cost (per part) | Typical Aluminum Parts |

| Extrusion | Med-High | Med-High | Gut | Low-Med | Profiles, heat sinks |

| Druckgießen | Hoch | Hoch | Gut | Low (at high vol) | Housings, complex shapes |

| CNC-Bearbeitung | Sehr hoch | Low-Med | Varies | Med-High | Precision components |

| Schmieden | Med | Med | Sehr hoch | Hoch | Critical load-bearing |

| Sheet Fabrication | Low-Med | Low-High | Mäßig | Low-Med | Enclosures, brackets |

We work closely with our customers to select the best manufacturing route for their specific aluminum parts, considering their design, quantity, and budget. Our service team provides complete supply chain services, including order management and quality control, to ensure the final aluminum parts meet every requirement.

This is a common question I hear: “Are aluminum parts really as strong as steel, or even stronger?” It’s an important consideration, especially for load-bearing applications.

While steel is generally denser and has higher tensile strength by volume, certain aluminum alloys, when considering their much lower weight, offer an excellent strength-to-weight ratio. This means aluminum parts can be designed to be very strong and durable for many applications where weight is a critical factor.

In my experience working with clients who import aluminum CNC parts, the discussion often revolves around achieving the necessary performance without unnecessary bulk. It’s not just about absolute strength, but smart design and material selection. As a supplier valuing engineering design and quality control, we help navigate these choices.

When we talk about “strength,” it can mean a few things:

Generally, if you take a piece of common steel and an equally sized piece of common aluminum, the steel will be stronger in terms of tensile and yield strength. It’s also generally harder.

However, this doesn’t tell the whole story for aluminum parts.

I always advise my clients, particularly purchasing managers concerned with specifications not meeting design requirements, that proper material selection and precise manufacturing are key. We ensure that the aluminum parts we supply, whether standard or custom, meet the agreed-upon strength and dimensional tolerance requirements through rigorous quality control. It’s about providing the right strength for the application, efficiently. For many projects, aluminum parts offer the perfect balance.

In conclusion, I believe aluminum parts offer remarkable versatility and performance. From their light weight to their manufacturing flexibility, they solve many common design and production challenges effectively.

This article has been generated by an AI and is for informational purposes only. While ALUT (lt-aluminum.com) specializes in customized aluminum products, please consult with our experts for specific advice related to your projects.