Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

I know the frustration of seeing product markings fade over time. You need durable parts that look professional, but standard printing often fails. Let me show you why laser engraving anodized aluminum is the ultimate answer for your needs.

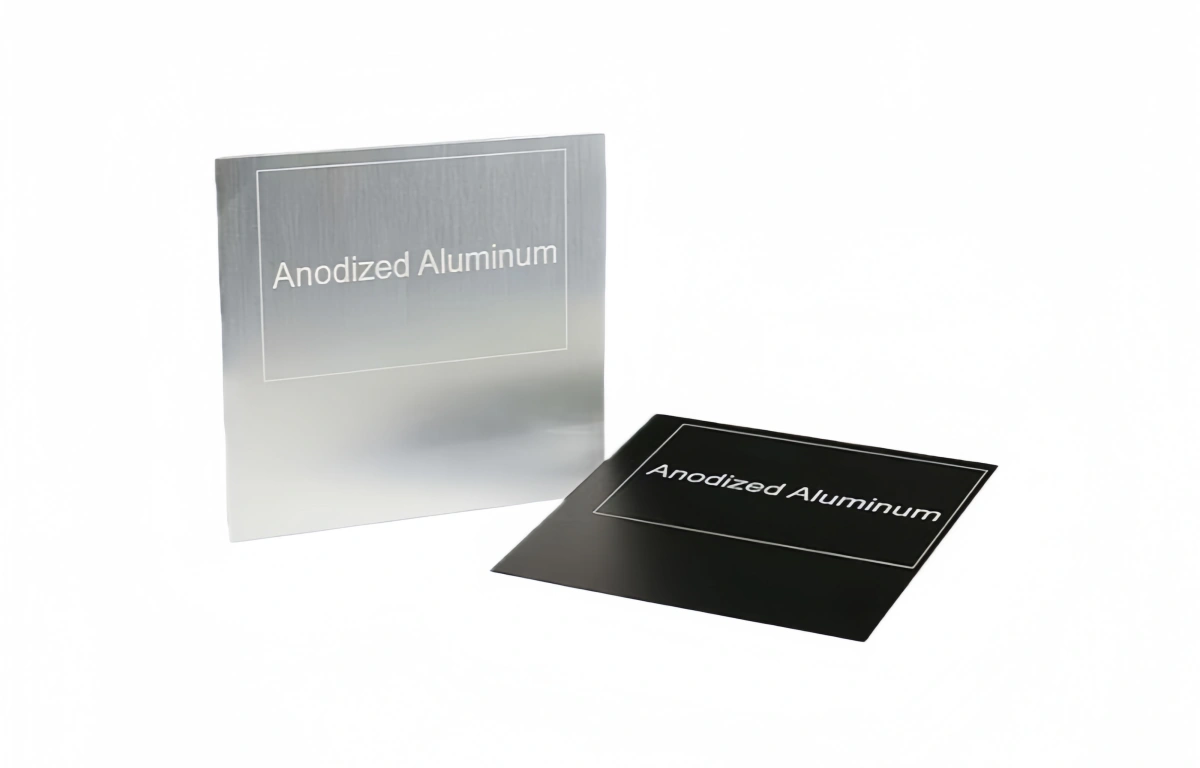

Laser engraving anodized aluminum creates permanent, high-contrast marks by removing the pigment without damaging the metal underneath. It offers superior durability and precision compared to screen printing, making it ideal for industrial parts and custom branding that must withstand harsh environments.

Read on to discover the exact steps and settings we use at our factory to guarantee perfect results every time you request laser engraving anodized aluminum for your orders.

You might worry that the laser will ruin the surface finish. I have heard this fear from many clients before they see our actual samples.

Yes, you can successfully perform laser engraving on anodized aluminum with excellent results. The laser beam bleaches or removes the dye layer, revealing a stark white or gray contrast against the colored background. It is highly effective for serialization, barcodes, and logos.

When we discuss manufacturing custom parts, the longevity of the logo or text is crucial. Many purchasing managers ask me if the engraving will last as long as the part itself. The answer lies in the unique nature of the material. When we perform laser engraving anodized aluminum, we are not adding ink to the surface. Instead, we are modifying the existing finish. This is a subtractive process. It strips away the color to show the base material or a bleached oxide layer.

There are three main reasons why laser engraving anodized aluminum is a successful method for industrial applications. First, it is permanent. Unlike stickers or ink, it cannot peel off. Second, it is fast. We can process hundreds of parts in a short time. Third, it is clean. There are no consumables like inks or solvents involved.

At ALUT, we often compare laser engraving anodized aluminum to other marking methods to help clients decide. If you are buying parts for electronics or machinery, you need to know the trade-offs.

| Feature | Laser Engraving | Screen Printing | CNC Engraving |

| Durability | Very High | Medium | High |

| Speed | Fast | Slow (drying time) | Slow |

| Detail Level | High (fine text) | Medium | Low (limited by tool) |

| Surface Feel | Smooth/Flat | Raised Ink | Deep Cut |

| Cost | Low (no tooling) | Medium (screens) | High (machine time) |

As you can see, laser engraving anodized aluminum strikes the best balance for most volume orders. It provides a premium look without the high cost of physical machining. It handles complex data like QR codes much better than CNC tools. For parts made in China or Vietnam, this efficiency helps keep your unit costs down while maintaining high quality.

Understanding the science helps you design better parts. Let me explain the mechanism simply so you can specify it correctly in your drawings.

The process involves directing a focused beam of light onto the anodized surface. The intense heat vaporizes the organic dye within the oxide layer, turning it white. Unlike deep etching, this method leaves the protective oxide layer largely intact, maintaining corrosion resistance.

The magic happens at a microscopic level. Anodizing creates a hard, porous layer on the surface of the aluminum. We fill these pores with dye to give the part its color. When we start laser engraving anodized aluminum, the laser beam hits this colored layer. The energy is absorbed by the pigment. This energy converts to heat instantly. This heat bleaches the dye.

The result is a high-contrast mark. If the part is black, the mark looks white or silver. If the part is red or blue, the mark is also whitish. This happens because laser engraving anodized aluminum removes the color but does not cut deep into the metal. This is vital for maintaining the protective qualities of the anodization. If we cut too deep, we expose raw aluminum. Raw aluminum can oxidize or corrode. By just bleaching the dye, the hard oxide layer remains to protect the part.

We typically use two types of machines in our factory when we execute laser engraving anodized aluminum:

For most projects involving laser engraving anodized aluminum, we aim for the “bleaching” effect. This looks the crispest. It is also the smoothest to the touch. When you run your finger over the logo, you barely feel it. This is what most premium electronic brands prefer. It feels integrated into the product, not just sat on top. When you send us your CAD files, providing vector art ensures the laser path is clean and sharp.

Wrong settings lead to burnt edges or faint marks. I have spent years tuning our machines to find that “sweet spot” for production.

The best power settings depend on your laser type, but generally, high speed and low power work best for laser engraving anodized aluminum. For a 30-watt fiber laser, use 20-30% power and high speeds (1000-2000 mm/s) to bleach the dye without cutting into the raw metal.

Finding the right settings is like cooking. If the heat is too high, you burn the food. If it is too low, nothing happens. In our facility, we run tests on every new batch. Anodizing thickness varies slightly between batches. A layer that is 10 microns thick reacts differently than one that is 25 microns thick, which affects how we approach laser engraving anodized aluminum.

The goal is to effect the dye, not the metal. If we use too much power during laser engraving anodized aluminum, we destroy the oxide layer. This creates a rough texture. It also looks gray or dark instead of crisp white. If we use too little power, the mark looks faded. It might look like a ghost image.

Speed is just as important as power. Moving the laser head fast prevents heat from building up in one spot. We want the heat to dissipate quickly. This keeps the edges of your letters sharp. If the laser moves too slowly, the heat spreads. This makes fine text look blurry.

Frequency (measured in kHz) also matters. For a bright white mark on black aluminum, high frequency is usually better. It polishes the surface as it marks.

Here is a general guide we use for a standard 30W Fiber Laser when performing laser engraving anodized aluminum. Note that these are starting points. We always adjust based on the specific alloy and color depth.

| Anodize Color | Power (%) | Speed (mm/s) | Frequency (kHz) | Expected Result |

| Black | 20-30% | 1500 | 30-40 | Crisp White |

| Blue/Red | 25-35% | 1200 | 30-40 | Frosted White |

| Clear/Silver | 40-50% | 1000 | 20-30 | Dark Grey/Black |

| Hard Anodize | 40% | 1000 | 30 | Off-White |

Notice the difference with Clear Anodize. Since there is no dye to bleach, we have to burn the surface slightly to get a dark contrast. This is a different look. For colored parts, low power is king. This approach saves energy and machine wear. It also ensures your parts look uniform from the first unit to the thousandth unit of laser engraving anodized aluminum production runs.

A dirty part looks cheap, even if the engraving is perfect. I ensure every piece leaving our factory is spotless and ready for assembly.

To clean residue after laser engraving anodized aluminum, wipe the area immediately with a non-abrasive cloth and denatured alcohol or a specialized cleaner like Magic Eraser. This removes the fine dust and smoke particles created during vaporization, restoring the crisp contrast of the design.

After the laser finishes its job, the part is not quite ready. The vaporization process creates dust. This dust is actually tiny particles of burnt dye and oxide. It settles right back onto the engraved area. To the naked eye, the logo might look yellowish or dull immediately after laser engraving anodized aluminum. This is a panic moment for new operators. But it is just surface dirt.

Cleaning is a critical step in our QC process. We cannot ship dirty parts to you. If we do, your assembly line gets dirty. Or worse, the end customer thinks the product is defective. We use specific solvents that dissolve the soot but do not harm the seal created during laser engraving anodized aluminum.

We use a simple but strict protocol.

Sometimes, cleaning does not fix the look. This usually points to a setting issue, not a cleaning issue.

| Issue Description | Cause | Solution |

| Yellow Tint | Too much heat / Burned dye | Increase speed or lower power. |

| Sticky Surface | Melted coating | Check if the part has a clear coat sealant. |

| Shadow/Ghosting | Dust settled and re-burned | Improve air extraction/exhaust during lasering. |

| Dull White | Residue still in pores | Scrub gently with melamine sponge and alcohol. |

Paying attention to these details is what separates a professional supplier from a basic job shop. We verify the contrast after cleaning. We use visual aids and sample limits. If a part does not pop, it does not ship. This attention to detail ensures that when you receive your shipment in the US or Europe, the results of our laser engraving anodized aluminum are ready for immediate use.

The technique of laser engraving anodized aluminum offers unbeatable durability and precision. At ALUT, we ensure precise results for your custom parts through strict process control. Contact me today to discuss your manufacturing needs.