Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

I know the frustration of seeing expensive metal parts corrode or scratch too quickly. You need a manufacturing solution that lasts, but choosing the right surface treatment often feels overwhelming and risky.

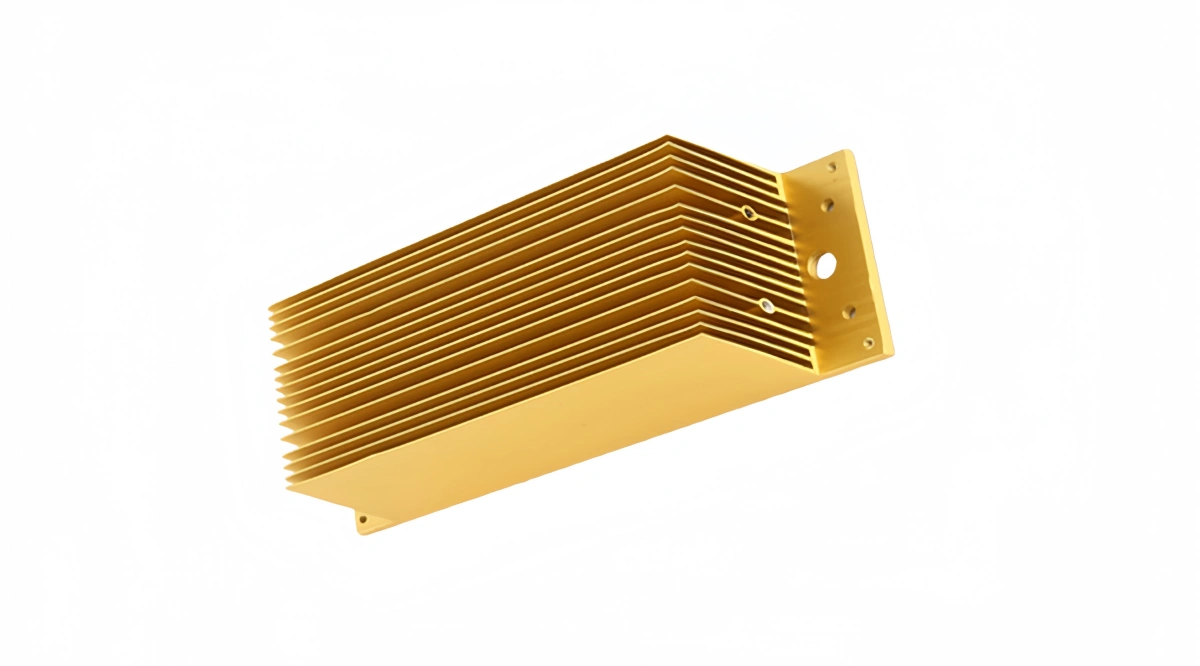

An anodized aluminum finish is an electrochemical process that converts the metal surface into a decorative, durable, corrosion-resistant, anodic oxide finish. It integrates with the aluminum substrate, meaning it cannot chip or peel like paint, making it ideal for tough industrial and architectural applications.

Let’s dive into exactly how this finish works and why it might be the perfect fit for your next project.

You might think all anodizing is the same, but I have seen many buyers make expensive mistakes here. Selecting the wrong type for your specific application can ruin your product’s performance and longevity.

There are three main types of anodized aluminum finish: Type I (Chromic Acid), Type II (Sulfuric Acid), and Type III (Hard Coat). Type II is the standard for coloring and general protection, while Type III offers the highest wear resistance for heavy-duty industrial parts and engineering applications.

When we discuss the types of anodized aluminum finish, we are really talking about the thickness and the density of the oxide layer. This is not just a cosmetic choice. It is an engineering decision. I often see drawings come into my factory with just “anodize” written on them. This is dangerous. You must specify the type to get the result you need.

This is the thinnest form. It creates a very soft and thin layer. We mostly see this in the aerospace industry. Why? Because it provides basic corrosion resistance but does not change the dimensions of the part very much. If you have a part with very tight tolerances, Type I is a safe bet. However, it is not good for dyeing. It is usually gray and does not look very decorative.

This is the most common type I deal with at ALUT. If you see a colored aluminum part, it is likely Type II. It balances cost, protection, and looks. The coating is thicker than Type I. It is porous enough to hold dye well. We can make it black, red, blue, or clear. It is hard enough for most consumer electronics and general machinery parts.

This is for the tough jobs. Type III is performed at lower temperatures and higher voltages. The result is a very dense and hard surface. It is almost as hard as diamond. We use this for gears, pistons, and military equipment. It is not about looks here. The color is usually dark gray or brown, and it is hard to dye brighter colors. But if wear resistance is your priority, this is the only choice.

Below is a comparison to help you choose the right spec for your order:

| Feature | Type I (Chromic) | Type II (Sulfuric) | Type III (Hard Coat) |

| Typical Thickness | 0.00005″ – 0.0002″ | 0.0002″ – 0.001″ | 0.001″ – 0.004″ |

| Wear Resistance | Low | Moderate | Excellent |

| Coloring Potential | Poor | Excellent | Limited (Dark colors) |

| Primary Use | Aerospace, tight tolerances | General manufacturing, cosmetic | Heavy machinery, friction parts |

I often tell my clients that choosing a cheap finish actually costs more in the long run. You want a product that looks professional and withstands harsh environments without constant replacement.

The main benefits of an anodized aluminum finish include superior corrosion resistance, enhanced durability, and electrical insulation. It also offers a metallic appearance that does not fade easily and provides a better surface for bonding primers and glues compared to bare metal or other plating methods.

In my experience running a factory, the biggest benefit customers look for is protection. Aluminum naturally forms an oxide layer, but it is thin and uneven. Anodizing makes this layer much thicker and uniform. This acts as a barrier. It stops moisture and salt from eating away at the raw metal. If you ship products to humid places like Southeast Asia or coastal areas in the US, an anodized aluminum finish is essential.

Unlike paint, anodizing does not cover up the metal texture. It celebrates it. The finish is part of the metal, not just a sticker on top. This gives your products a premium “metallic” look that plastic or painted steel cannot match. For my clients making high-end audio equipment or medical devices, this premium look allows them to sell their products at a higher price point.

This is a technical point that many purchasing managers overlook. The anodized surface is porous before we seal it. This structure acts like a sponge. It grabs onto lubricants, adhesives, or primers. If you need to glue two parts together, or if you need to paint over a part later, an anodized base ensures the bond is strong. It prevents the top layer from peeling off later.

Many plating processes are dirty. They use heavy metals and dangerous chemicals that are hard to dispose of. Anodizing is water-based. It is generally safe for the environment compared to other finishing processes. The byproduct is mostly aluminum hydroxide, which is harmless. If your company has strict sustainability goals, this finish is a smart choice.

Here is how anodizing stacks up against other common finishes:

| Feature | Anodized Finish | Powder Coating | Wet Paint |

| Integration | Integrated with metal | Surface layer only | Surface layer only |

| Chip Resistance | Will not peel | Can chip or peel | Can chip or scratch |

| Look | Metallic, premium | Plastic-like, thick | Variable |

| UV Stability | Very Good (Inorganic) | Good | Fair to Good |

You need to know if your investment will survive ten or twenty years in the field. I understand that replacing parts due to surface failure is a logistical nightmare and damages your brand reputation.

A high-quality anodized aluminum finish typically lasts between 10 to 20 years, depending on the thickness of the coating and the environment. In controlled indoor settings, it can last indefinitely, while harsh coastal environments may shorten its lifespan without proper maintenance and cleaning.

When a client asks me, “Wilson, how long will this last?”, I have to ask them where they will use it. The lifespan of an anodized aluminum finish is not a fixed number. It depends heavily on the “sealing” process we do at the factory and the environment where the product lives.

After we anodize the aluminum, the surface has millions of tiny pores. If we leave them open, dirt and oil will get inside and ruin the look. We must seal these pores. We use hot water or nickel acetate to close them. A well-sealed part locks the color in and keeps corrosion out. If a factory rushes this step to save money, the lifespan drops significantly. At ALUT, we monitor sealing time strictly because we know this determines the life of the part.

Sunlight is a major factor. Ultraviolet (UV) light can fade the dye used in Type II anodizing over time. If your product sits outside in Arizona or Spain, organic dyes might fade in a few years. For these cases, we recommend “electrolytic coloring” (2-step sealing) which is much more stable against UV light.

Salt is the other enemy. In coastal regions, salt spray attacks metal. A standard Type II coating might show pitting after 5 to 8 years near the ocean. However, a thicker Type III coating can resist this for much longer.

The finish is hard, but it is not magic. If the part rubs against other metal parts constantly, it will eventually wear down. Type III (Hard Coat) handles this much better than Type II. For static parts, like window frames or electronics housings, the finish will likely outlast the internal components of the device.

To ensure you get the maximum lifespan, you need to specify the right thickness in your purchase order. A thin class might be cheaper now, but if it fails in 3 years, the warranty costs will destroy your profit.

I have seen great products look terrible after just one year because of bad cleaning habits. You want to keep your parts looking new without damaging the protective layer with the wrong chemicals.

To clean an anodized aluminum finish, use a neutral pH detergent mixed with water and a soft cloth or sponge. Avoid acidic or alkaline cleaners, steel wool, or abrasive pads, as these can permanently damage the oxide layer and ruin the appearance.

Maintenance is simple, but it requires discipline. The anodized layer is a ceramic-like material. It is hard, but it is chemically sensitive to high and low pH. The biggest mistake I see is people using strong industrial cleaners used for masonry or steel. These will eat the aluminum oxide instantly.

You must use a neutral cleaner. Look for a pH between 6 and 8. Dish soap is usually a safe choice. If you use a cleaner that is too acidic (like vinegar) or too alkaline (like bleach or strong degreasers), you will see “etching.” This makes the smooth, shiny surface look cloudy and rough. Once this happens, you cannot fix it. You would have to strip the part and re-anodize it, which is very expensive.

Do not use abrasive tools. I know it is tempting to use a green scrubbing pad to remove a tough stain. Do not do it. It will scratch the surface. Use a soft sponge or a microfiber cloth.

If your parts are outside, clean them more often. Dirt and grime hold moisture against the metal. This moisture can be acidic (acid rain) or salty. Cleaning it off every six months helps the anodized aluminum finish do its job. If you ignore it for years, the dirt becomes a crust that traps corrosive elements, and the coating will eventually fail.

Here is a quick guide to share with your maintenance team:

| Do This | Do Not Do This |

| Use neutral pH soap (pH 6-8) | Use acid or bleach (pH <5 or >9) |

| Use soft sponges or cloth | Use steel wool or sandpaper |

| Rinse with fresh water | Leave soap residue on the part |

| Clean regularly (every 6 months) | Use a pressure washer at high power |

Anodized aluminum finish provides unmatched durability and style. By choosing the correct type and maintaining it properly, your products will last for decades. At ALUT, we ensure every specification is met precisely.