Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Tired of cracked aluminum parts ruining your production schedule? This common issue wastes time and money. I’ll show you the professional secrets to perfect bends every time.

In my factory, successful bending aluminum sheet metal comes down to three key factors: choosing the right alloy, using the correct bend radius, and controlling the forming process. Mastering these elements is the secret to getting clean, crack-free results for any project.

These are the exact principles my engineering team applies daily for our clients in the US and Europe. Let’s break down each critical step so you can confidently source or produce perfectly formed aluminum parts.

Confused by terms like air bending and coining? Using the wrong technique causes defects and inconsistent angles. Let me clarify the best methods for flawless results.

From my factory’s perspective, the most common technique for bending aluminum sheet metal is air bending. It is versatile and requires less force. For higher precision, we sometimes use bottoming, but we choose the method based on the part’s required accuracy and design.

Choosing the right technique is a critical decision in the process of bending aluminum sheet metal. It affects everything from the accuracy of the final angle to the stress placed on the material. When a purchasing manager sends me a drawing, one of the first things my engineers determine is the best bending method. The choice depends on the project’s specific needs, like tolerance, quantity, and cosmetic appearance.

Air bending is the most widely used method in our factory. In this process, the punch presses the sheet metal into the V-die, but it does not push it all the way to the bottom. The sheet touches only three points: the tip of the punch and the two top edges of the V-die. The final angle is controlled by how deep the punch pushes the metal. This method is very flexible. We can create different angles using the same tooling, just by changing the stroke depth. However, it is very sensitive to variations in material thickness and temper.

Bottoming is a more precise technique. Here, the punch pushes the sheet metal so it makes full contact with the surfaces of the die. This reduces springback and provides much better angular consistency. It requires more force than air bending and the tooling must match the desired final angle. Coining is an even more extreme version of bending aluminum sheet metal. It uses immense force to stamp the material, thinning it at the bend and forcing it to conform to the tool’s exact angle.

Here is a comparison I often share with clients:

| Bending Technique | Precision | Tonnage Force | Springback Effect | Common Use |

| Air Bending | Good | Low | High | Most general purpose bends |

| Bottoming | Better | Medium to High | Low | High-precision angles |

| Coining | Best | Very High | Almost None | Stamping, not ideal for aluminum |

Think any old tool will work for the job? Using the wrong equipment will damage your material and potentially the machine. Let’s cover the essential tools for professional results.

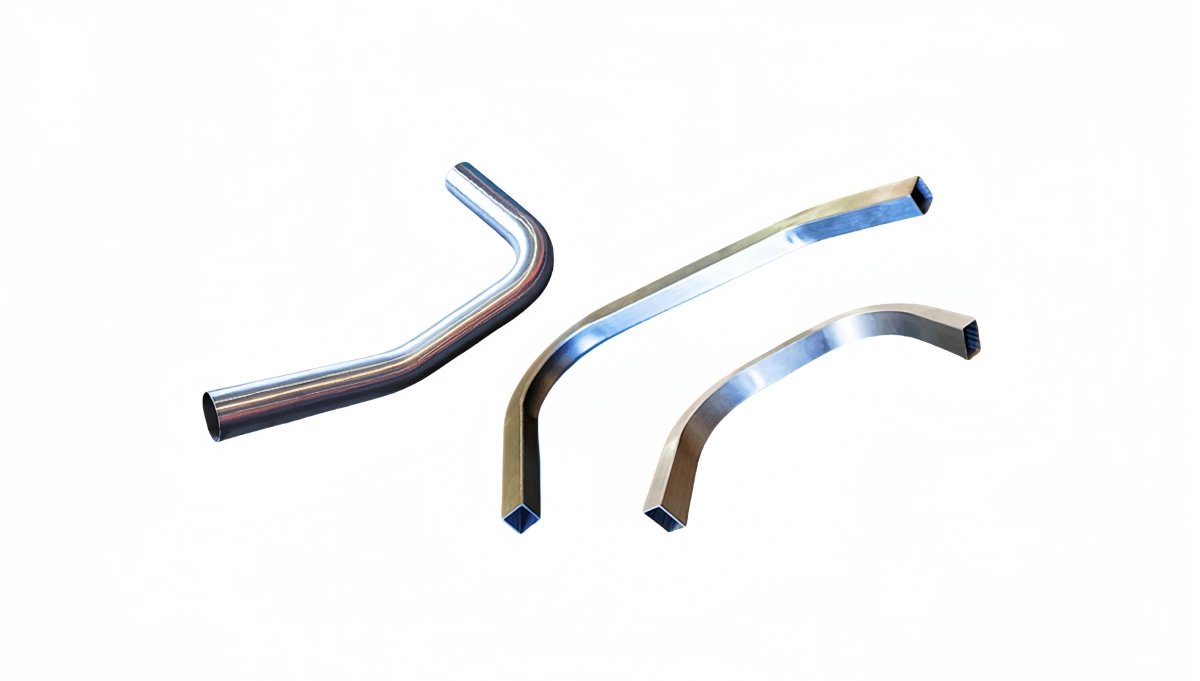

In my professional experience, the essential tools for bending aluminum sheet metal are a press brake, along with a specific punch and die set. The shape and radius of this tooling are the most critical factors for preventing cracks and achieving the correct angle.

Having the right equipment is non-negotiable for quality manufacturing. For bending aluminum sheet metal, this means more than just having a machine. It means having the correct machine and the correct tooling for the specific alloy and thickness. I have seen many projects fail because a supplier tried to use steel tooling setups for aluminum parts, resulting in scratches, cracks, and incorrect angles. Our factory maintains a large inventory of tooling specifically for aluminum to avoid these issues.

The press brake is the core machine used for bending aluminum sheet metal. It is a machine that holds the punch and die and provides the controlled force needed to form the metal. Modern press brakes, like the ones we use, are CNC (Computer Numerical Control) operated. This allows us to program the exact bend angle, stroke depth, and back gauge position.

The punch is the top tool that presses down on the sheet, and the die is the bottom tool that the sheet is pressed into. They work together as a set.

| Tool Component | Primary Function | Key Consideration for Aluminum |

| Press Brake | Provides controlled force | CNC control for high repeatability |

| Punch (Top Tool) | Creates the inside of the bend | Radius must not be too sharp |

| Die (Bottom Tool) | Supports the sheet and forms the outside | V-opening width determines the bend radius |

Are cracks at the bend line a constant headache for your projects? This common failure point wastes expensive material. I will share my factory’s proven methods to eliminate it.

Based on years of troubleshooting, I can tell you that stopping cracks when bending aluminum sheet metal involves three things: using a large bend radius, bending across the grain, and selecting a softer alloy or temper. These steps are fundamental to our quality control.

Cracking is the number one enemy when bending aluminum sheet metal. It is an immediate sign that the material has been stressed beyond its limit. For a purchasing manager, receiving a batch of cracked parts is a major problem that can halt a production line. This is why we have built our entire process around preventing this single issue. It is a combination of proper design, material selection, and machine setup.

Like wood, rolled aluminum sheet has a grain direction. The grain is formed as the aluminum slab is rolled into a thin sheet. The metal is stronger and less ductile along the grain. If you try to bend parallel to the grain, you are essentially trying to split the material along these lines, which makes cracking much more likely. The correct way is to orient the part so that the bend line goes across, or perpendicular to, the grain direction. This simple step dramatically increases the chances of a successful bend. For critical parts, we always check the grain direction before bending.

Not all aluminum is the same. Some alloys are designed for strength, while others are designed for formability. Trying to make a tight bend in a high-strength alloy like 6061-T6 is a common mistake.

Here is a quick reference for common alloys:

| Aluminum Alloy | Formability/Bending | Common Temper | Primary Use Case |

| 1100 | Excellent | H14, O | General, where formability is key |

| 3003 | Very Good | H14, O | General fabrication, enclosures |

| 5052 | Excellent | H32, H34 | Marine, sheet metal, electronics |

| 6061 | Poor to Fair | T6, T4 | Structural, when bending is minimal |

Are your designs failing because the bends are too tight? Specifying the wrong radius is a costly design flaw. Let me give you the safe numbers to use for your projects.

In my factory, the minimum radius for bending aluminum sheet metal depends entirely on the alloy, temper, and thickness. For a common alloy like 5052-H32, a radius of 1 to 2 times the thickness is safe. For stronger alloys, it must be much larger.

The minimum bend radius is the smallest internal radius you can create without cracking the material on the outside of the bend. This is perhaps the most important single parameter in the entire process of bending aluminum sheet metal. When we receive a drawing from a client, this is the first thing we check. If the specified radius is too small for the chosen material, we immediately flag it for review.

The minimum bend radius is almost always expressed as a multiple of the material’s thickness (T). For example, a “2T” radius for a 2mm thick sheet would be 4mm. A smaller “T” value means the material can handle a tighter bend. Softer materials like 1100-O can sometimes be bent to a 0T radius (a sharp corner), while a hard material like 6061-T6 might require a radius of 6T or more. This rule is a fundamental part of a successful bending aluminum sheet metal operation.

When you bend a sheet, the metal on the outside of the bend stretches, while the metal on the inside compresses. If the radius is too tight, the outer surface stretches too much and exceeds its tensile strength, causing it to crack. A larger radius distributes this stretching force over a greater area, keeping the stress below the material’s failure point. This is why a generous radius is your best friend when bending aluminum sheet metal. It’s always better to design with a slightly larger radius than the absolute minimum to create a safety margin and ensure a robust manufacturing process.

Mastering the basics of technique, tooling, and material is the key. Proper bending aluminum sheet metal ensures high-quality, durable parts for any project you manage.